Choosing the best chainsaw chain

Finding the right chain for your chainsaw is very important. Not only the efficiency of work depends on this, but also the ability to efficiently cut various species and types of wood. The main problem is that even professionals do not always remember which chain to take for their saw. This may be due to the fact that chain wear, with regular seasonal use, takes several years.

Finding the right chain for your chainsaw is very important. Not only the efficiency of work depends on this, but also the ability to efficiently cut various species and types of wood. The main problem is that even professionals do not always remember which chain to take for their saw. This may be due to the fact that chain wear, with regular seasonal use, takes several years.

Experts recommend having a set of several chains. This allows them to be replaced as needed. Also, this approach takes advantage of all the advantages of mechanical sharpening.

Varieties of chains for chainsaws

First, you should understand the types of chains for chainsaws, before proceeding with their choice.

First, you should understand the types of chains for chainsaws, before proceeding with their choice.

The types of saw headsets are as follows:

- household;

- semi-professional;

- professional.

Not only the quality and used material depends on the design features, but also other parameters of the chain. In your choice, you must rely mainly on the characteristics of the chainsaw. Otherwise, an incorrectly selected saw headset can put too much stress on the engine and the owner will soon need to make a major overhaul.

Saw chains are of the following types:

- Chippers are universal. They are used in everyday life and individual construction. They are also chosen for cutting logs into boards by professionals. As a rule, the latter install them on LOGOSOL sawmills. Corresponding to the correct sharpening angle (about 10 °) allows the chains to cut fairly quickly along the wood fibers, which is why they are especially appreciated in sawmills.

- Chizselnye - show themselves well in cross-section. Most often used by professionals. The chisel chain does a good job of cutting across. However, when sawing lengthways, it is less efficient than a chipper, even when sharpened correctly.

The differences between the chains lie in the types of teeth, which, depending on their shape, can have a noticeable effect on the possible performance parameters.

Sharpening chains for a longitudinal cut should be done in service centers. With certain skills, you can do it yourself. Since such headsets are rarely found on the free market.

There is also a separate type of chains for chainsaw, they are called special. These saw sets have a special purpose - working with concrete, aerated concrete, or carrying out rescue operations. The design of the teeth is also different, but basically all the difference is in the materials used. Sawing concrete slabs without much effort, you can chain with victorious solders. But they are expensive. So for a common man in the street, buying them may be simply inappropriate.

Most standard chains are based on chromium-nickel steel. To work with hardwood or solid wood that has sufficient density, you will need to select the option with carbide links. The high cost of which is their main disadvantage.And to sharpen them correctly, you will need equipment equipped with corundum tips.

About teeth

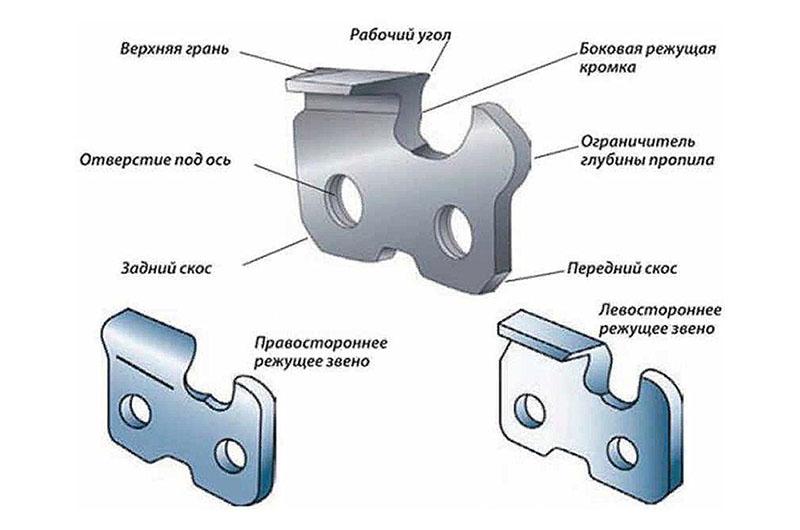

The teeth have a very specific design. To learn how to work with a chain and sharpen it correctly, you need to know the basic material. With its specificity of work, the chainsaw is a bit like a plane. Because of this, it is necessary to know which links require care.

The teeth have a very specific design. To learn how to work with a chain and sharpen it correctly, you need to know the basic material. With its specificity of work, the chainsaw is a bit like a plane. Because of this, it is necessary to know which links require care.

The design of the cutting and working links is not so simple. Each link has:

- vertical end and upper horizontal edges of the blades;

- scapula;

- base with a hole for the axle;

- stop for the set cutting depth.

It is from the presence of such parts and components that the quality of cutting materials depends.

What are the parameters for choosing a chain for a chainsaw

Depending on the basic parameters of the chainsaw, professionals choose a chain. Work attachments also differ in their characteristics, as they are designed to perform different tasks. That is why the replacement chain must be selected correctly, as well as the equipment for its sharpening. What indicators need to be taken into account?

Depending on the basic parameters of the chainsaw, professionals choose a chain. Work attachments also differ in their characteristics, as they are designed to perform different tasks. That is why the replacement chain must be selected correctly, as well as the equipment for its sharpening. What indicators need to be taken into account?

Step

Step is one of the most important parameters. It is according to him that they are usually guided when choosing chains for chainsaws, in contrast to round links, in which the caliber is of the greatest importance. Measure the step realistically and independently. To do this, you need to apply a ruler in the direction from the first to the third link of the rivets. Data is expressed in inches. Possible production, and hence productivity, is in direct proportion to the set value.

Step is one of the most important parameters. It is according to him that they are usually guided when choosing chains for chainsaws, in contrast to round links, in which the caliber is of the greatest importance. Measure the step realistically and independently. To do this, you need to apply a ruler in the direction from the first to the third link of the rivets. Data is expressed in inches. Possible production, and hence productivity, is in direct proportion to the set value.

Choosing too large a step can create a high load on the motor, which often leads to potential breakdowns. Therefore, it is always necessary to check the power of your saw.

Standard step sizes determine the purpose of the tools and the scope of their use (see table).

| Step | Description |

| 0,25 | Rare and almost never used |

| 0,325 |

These options are intended for household and semi-professional chainsaws. |

| 0,375 | |

| 0,404 | Chains with this pitch can be used for semi-professional and professional type tools. |

| 0,75 | Used only for professional units, but it is quite difficult to buy |

Using this table, you can understand what type of saw headset the user needs at a given time, based on the step of the tool.

Shank thickness

Another point that must be taken into account when choosing chains for chainsaws is the thickness of the shank. The tail section is the section of the chain that is located inside the tire. The thickness of this part for many chains can be different, so you should choose based on the power of the chainsaw. Simply put, the smaller the installed tire, the thinner the shank should be.

Another point that must be taken into account when choosing chains for chainsaws is the thickness of the shank. The tail section is the section of the chain that is located inside the tire. The thickness of this part for many chains can be different, so you should choose based on the power of the chainsaw. Simply put, the smaller the installed tire, the thinner the shank should be.

In parallel, the step must be taken into account. The latter, in this case, remains the most important parameter. Further, you can see a table by which you can quickly understand what thickness of the shank should be selected.

| Step | Thickness |

| 0,25 | 1.1 mm |

| 0,325 | 1.3 mm |

| 0,375 | 1.5 mm |

| 0,404 | 1.6 mm |

| 0,75 | 2 mm |

Using this simple table, you can quickly understand the algorithms for the dependence of the shank thickness on the chain pitch. But that's not all. There are a few more points to consider.

Bus length

A bar, if made of quality material, can last at least twice as long as the chain with careful saw operation. The dimensions of the new chain directly depend on the length of the bar. Therefore, before going to the store for a new chain, the user will need to measure the tire first. Typically, the size is indicated on the side. Sometimes this information is written only in the saw's passport. This must always be borne in mind. After all, you can measure the tire with a ruler.

A bar, if made of quality material, can last at least twice as long as the chain with careful saw operation. The dimensions of the new chain directly depend on the length of the bar. Therefore, before going to the store for a new chain, the user will need to measure the tire first. Typically, the size is indicated on the side. Sometimes this information is written only in the saw's passport. This must always be borne in mind. After all, you can measure the tire with a ruler.

If you are going to change the bar and chain one size up, you should consider the power of the tool. This is usually done on an exceptional basis if the engine characteristics permit. There is more detailed information about this in the passport.Also, the admissible length of the bus is often written there.

Cutting depth

Large teeth provide a deep cut in one pass. Accordingly, the depth of cut directly affects the working speed. It is important to note that this parameter seriously affects the engine, and the chainsaw may not cope with the load.

Large teeth provide a deep cut in one pass. Accordingly, the depth of cut directly affects the working speed. It is important to note that this parameter seriously affects the engine, and the chainsaw may not cope with the load.

The height of the links determines the strength of the teeth. The more, the less durable they are. According to the standard, they are made in two versions: 0.635 and 0.762 mm. They are classified as low profile if the profile is small and if large as high profile. The cutting speed of wood directly depends on the depth of cut.

Sequence of teeth arrangement

The teeth in the chain can be positioned in different ways.

The teeth in the chain can be positioned in different ways.

Each type has its own characteristics:

- Standard.

- With a half-pass.

- With a pass.

The most popular options are with a pass because they load the engine less. Professional units use the standard version, but semi-skip chains can be used for semi-professional and household ones. Sometimes they are installed to unload the motor on the saws.

Chainsaw chain: sawing types

Chainsaws are mainly common, the chains of which are intended for cross-cutting. Rip cuts are needed much less frequently. Moreover, if it is necessary to use such a saw headset, it must be borne in mind that it is more difficult to acquire it, since it costs much more.

Chainsaws are mainly common, the chains of which are intended for cross-cutting. Rip cuts are needed much less frequently. Moreover, if it is necessary to use such a saw headset, it must be borne in mind that it is more difficult to acquire it, since it costs much more.

The difference between both options is the sharpening angle. The transverse angle is 25-30 °, while the longitudinal one has 10 °. Finding out what method the headset is intended for is not difficult, you just need to look at its device.

If the teeth can be heat treated, then the chain must not be sharpened. Such options usually have a very long service life, but if they are dull, they should be replaced immediately.

How to count links

Users often do not know how to count the links on a chain. And this is important, because a small mistake can buy the wrong option. It is possible that the chain will not fit on the tire and will have to be spent again.

Users often do not know how to count the links on a chain. And this is important, because a small mistake can buy the wrong option. It is possible that the chain will not fit on the tire and will have to be spent again.

There are two simple methods:

- By shanks. To avoid confusion, it is recommended to mark the first shank. For example, a marker. But a piece of paper or tape will also work.

- Recalculate all connecting links. It is advisable to remove the chain, straighten it on a flat surface. Fold in half and count them in pairs.

If, during the counting, you are mistaken in the big direction by only one link, you should not worry. This will not have a noticeable effect on work efficiency. But a downside mistake will have serious consequences, since you can buy a chain that is too short. With all the best efforts, it will not be possible to put it on the tire and install it on the chainsaw.

How to sharpen a chainsaw chain

Sooner or later, the chain will become dull during operation. You will need to sharpen it. You can understand that she needs it.

Sooner or later, the chain will become dull during operation. You will need to sharpen it. You can understand that she needs it.

The following signs will prompt:

- decrease in efficiency;

- the appearance of vibration;

- the presence of deviations from the expected cutting line;

- altered sawdust, with uneven and needle-like edges;

- the need to make serious physical efforts to perform the action.

Increased chain wear causes systematic collisions with hard materials (concrete, stone, earth, wood knots). The banal inept handling of the instrument also contributes.

Among the possible sharpening methods, several can be distinguished: using a file, a grinder and an electric sharpening machine.

We sharpen the chainsaw chain with a file

To sharpen the chain you need:

- Clamp the tire firmly (before doing this, apply the chain brake). The chainsaw must be secured carefully, it is best to clamp it in a vice. This will give a good chance for a successful sharpening.

- Position the template so that the “arrow” is directed to the “nose” of the tire. It is worth making a mark, you can use chalk.It is only necessary to mark the tooth from which the sharpening of the chain began, in order to avoid the likelihood of going in a second circle, which is highly undesirable.

- Sharpening should be directed in the direction indicated by the arrows. It must be remembered that there is a factory notch on each tooth of the chain. It indicates the maximum possible sharpening angle.

Restrictors are sharpened as needed. Usually they are processed every 2-3 sharpenings.

It is necessary to move the file "away from you" and the number of movements for each tooth should be the same.

Buying a sharpening tool should be more expensive. Since the cheap options become unusable after the first use.

Grinder for sharpening the chain

Sharpening with a grinder is carried out as follows:

- Lock the chainsaw (apply the chain brake). The chain does not need to be removed, it must remain on the tire.

- Pin on Bulgarian cutting disc for metal with a thickness of no more than 2 mm. It is desirable to take with an already worked edge.

- Sharpen at the desired angle. To do this, carefully, observing the sharpening angle, remove a small layer of metal, first from one side of the tooth, and then from the other.

With the right approach, one chain can be sharpened in this way up to 7 times. But it is worth considering - the method is dangerous, you must follow safety precautions.

Chain sharpening machine

The last method is to use a specialized electric grinder. The example will consider the option with a manual drive. It is similar in design to a bow saw. Only instead of a saw blade there is a round file, thanks to which you can quickly and easily sharpen the chain teeth.

The last method is to use a specialized electric grinder. The example will consider the option with a manual drive. It is similar in design to a bow saw. Only instead of a saw blade there is a round file, thanks to which you can quickly and easily sharpen the chain teeth.

Would need:

- Fix the chain in a vise.

- Sharpen the tooth with a few precise movements.

- Go to next.

Before that, you may need to configure all the parameters on the machine itself. The exact instructions depend on the chainsaw used and the machine model.

After finishing sharpening, it is advisable to blow the chain with compressed air. And then leave it in fresh engine oil for a while. And although no one usually does this, this approach has a good effect on the longevity of the saw headset as a whole.

What specific sharpening method to choose depends on financial capabilities. The duration of operation is determined by the quality of the chain. The accuracy of working with a chainsaw also affects.

If you are going to buy a chain for a chainsaw, you should definitely study all possible options in detail. Specialists will definitely help with this. One has only to look at the range of online stores. It is necessary to select a saw headset based on its tasks and the material with which it is planned to work. It is better to overpay a little than to buy a low-quality product, because of which the saw may stop working.

If you are going to buy a chain for a chainsaw, you should definitely study all possible options in detail. Specialists will definitely help with this. One has only to look at the range of online stores. It is necessary to select a saw headset based on its tasks and the material with which it is planned to work. It is better to overpay a little than to buy a low-quality product, because of which the saw may stop working.