Do-it-yourself attic staircase for a private house

An attic staircase is a fairly simple design that is not difficult to make yourself. This element can be of a solid type made of wood or metal, and it can also be lightweight and have a folding mechanism. In this case, the main thing is to draw up a drawing correctly, calculate important parameters, choose a staircase option for the attic and make it with your own hands in a quality manner.

An attic staircase is a fairly simple design that is not difficult to make yourself. This element can be of a solid type made of wood or metal, and it can also be lightweight and have a folding mechanism. In this case, the main thing is to draw up a drawing correctly, calculate important parameters, choose a staircase option for the attic and make it with your own hands in a quality manner.

What is an attic staircase

Today, the following types of stairs are produced on an industrial scale:

- stationary;

- portable;

- foldable.

Each type of this product has its own advantages and disadvantages. It is necessary to make a choice, taking into account the area of free space, as well as the possibility of independently creating an attic staircase.

To create this structure, you will need the following set of tools:

- roulette;

- chisel;

- hacksaw;

- square;

- screwdriver;

- joiner's glue;

- polyurethane foam.

In addition, for work you will need a set of materials:

- wooden blocks;

- boards for racks (bowstrings) and steps;

- plywood sheets;

- articulated joints;

- screws and bolts;

- powerful hinges or piano designs;

- shock absorbers.

The main parameters of the future design

The main parameter that you need to pay attention to is the operating load that the staircase to the attic can withstand. In addition to the main weight of a person, additional cargo is also taken into account. The optimal parameter is 150 kg. Also, to select the type of structure, it is necessary to take into account the parameters of the room in which the hatch will be equipped. For this, the height of the ceiling, its area and the place that the staircase will occupy is taken into account.

The main parameter that you need to pay attention to is the operating load that the staircase to the attic can withstand. In addition to the main weight of a person, additional cargo is also taken into account. The optimal parameter is 150 kg. Also, to select the type of structure, it is necessary to take into account the parameters of the room in which the hatch will be equipped. For this, the height of the ceiling, its area and the place that the staircase will occupy is taken into account.

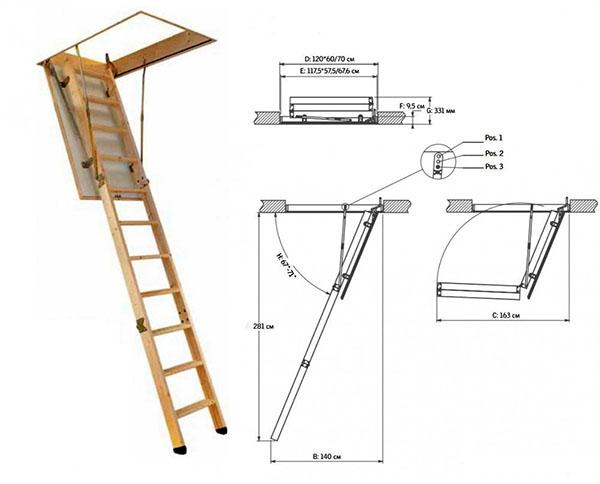

In addition, it is important to correctly determine the slope of the product, otherwise it will be inconvenient and even dangerous to climb along it. A suitable angle of inclination for an attic staircase is 45 degrees. This parameter directly depends on the height of the structure. Next, the parameters of the opening in the ceiling are calculated. It is not recommended to make the hatch too large. The width of the opening should not exceed 800 mm and the length should be about 1200 mm.

In addition, it is important to correctly determine the slope of the product, otherwise it will be inconvenient and even dangerous to climb along it. A suitable angle of inclination for an attic staircase is 45 degrees. This parameter directly depends on the height of the structure. Next, the parameters of the opening in the ceiling are calculated. It is not recommended to make the hatch too large. The width of the opening should not exceed 800 mm and the length should be about 1200 mm.

The dimensions of the attic staircase should be within 300 cm - exceeding this parameter will make the structure unsafe.

Manufacturing and installation of attic stairs

Folding ladder on attic manufactured in three separate sections. It is recommended to equip this structure with a special element that prevents slipping. Wooden products should have a corrugated surface, and metal products should have a notch. It is also extremely important to consider that it is necessary to provide for a special mechanism that will allow the stairs to open and close smoothly. For this purpose, hinge joints are installed or conventional door hinges are used.

The process of phased manufacturing and installation of an attic staircase with a hatch is as follows.

Manufacturing box and hatch

First, a box is made in which the ladder will be placed when folded. The box is installed in the ceiling opening. To make it, you need a board in width equal to the attic floor. It needs to be processed and cut into elements.Next, the elements are glued with wood glue, and then twisted with self-tapping screws (diameter - 5).

First, a box is made in which the ladder will be placed when folded. The box is installed in the ceiling opening. To make it, you need a board in width equal to the attic floor. It needs to be processed and cut into elements.Next, the elements are glued with wood glue, and then twisted with self-tapping screws (diameter - 5).

Now the hatch itself is being made. Take five bars (two shortened and three longer) for the frame. The size of the elements is 50x50 mm. One of the long ones is attached to the center of the frame for added rigidity. The junction points are treated with wood glue.

Now the hatch itself is being made. Take five bars (two shortened and three longer) for the frame. The size of the elements is 50x50 mm. One of the long ones is attached to the center of the frame for added rigidity. The junction points are treated with wood glue.

Next, a plywood sheet (approximately 8x10 mm) is placed on a frame made of bars. The plywood sheet is screwed to the parts using 50 mm self-tapping screws.

Next, a plywood sheet (approximately 8x10 mm) is placed on a frame made of bars. The plywood sheet is screwed to the parts using 50 mm self-tapping screws.

How the attic staircase is assembled

To assemble the stairs, boards are used that are designed for racks or bowstrings. The two boards must be fastened together with tape to accurately mark the lengths of the sections, holes for fasteners and grooves for steps. In two boards, a through hole is simultaneously made in the form of a semicircle. Pivot joints are inserted into this hole.

To assemble the stairs, boards are used that are designed for racks or bowstrings. The two boards must be fastened together with tape to accurately mark the lengths of the sections, holes for fasteners and grooves for steps. In two boards, a through hole is simultaneously made in the form of a semicircle. Pivot joints are inserted into this hole.

Then a board with a hole is sawn in the center - these are the future racks (bowstrings) for the stairs. They are fastened with a mechanism that allows you to unfold the structure.

Then a board with a hole is sawn in the center - these are the future racks (bowstrings) for the stairs. They are fastened with a mechanism that allows you to unfold the structure.

The next step is the markings for installing the steps. At this stage, use a bean.

To make the markings symmetrical, it is better to make it on two boards bonded at once.

Now they make cuts, and then remove unnecessary parts with a chisel. Next, the boards for the steps are cut, mounted in grooves and fastened with wood glue.

Now they make cuts, and then remove unnecessary parts with a chisel. Next, the boards for the steps are cut, mounted in grooves and fastened with wood glue.

All steps must be secured with self-tapping screws. The remaining sections for the stairs are made in a similar way.

Proceed to fasten the hinge joints. You can buy a similar mechanism at any hardware or furniture store. But you can also make them yourself. The parts are installed on sections of the folding ladder that have been drilled in advance. The connecting bolt of the hinge mechanism is installed in the sawn groove. Similarly, hinges are installed in other sections of the ladder.

Next, go to the fasteners that will hold and open the hatch. To do this, use the piano loops. They are installed on the edge of the box with a thin drill.

Next, go to the fasteners that will hold and open the hatch. To do this, use the piano loops. They are installed on the edge of the box with a thin drill.

At this stage, the box must be securely "mounted" into the ceiling opening. It is attached to the walls of the fortified opening with nails or self-tapping screws. The resulting gaps are filled with polyurethane foam. Then hinges for the hatch are attached to the box and temporary diagonal bars are additionally installed.

A frame is installed on temporary stands, hinged hinges are mounted on its edge and screwed on. For the purpose of thermal insulation, any material for insulation is used and sheathed inside the hatch. Then the frame must be additionally covered with a plywood sheet.

A hinge mechanism is now installed that will fix the lower part of the hatch. This may be the simplest option - two metal hinges fastened together.

A hinge mechanism is now installed that will fix the lower part of the hatch. This may be the simplest option - two metal hinges fastened together.

Installation of an attic staircase

Next, proceed to the installation of the attic staircase and securing the upper section. To do this, use brackets that are screwed to the inside or outside of the structure.

Next, proceed to the installation of the attic staircase and securing the upper section. To do this, use brackets that are screwed to the inside or outside of the structure.

Finally, it is necessary to think over a mechanism that will reliably close the hatch and hold the attic staircase. As a temporary option, you can use a latch bar, which is screwed on with an ordinary self-tapping screw. If you choose a more complex option, in which this mechanism will be automated and the hatch will be held on the box. Additionally, the attic staircase is supplemented with shock absorbers (springs).

Mineral wool, foam rubber or expanded polystyrene can be used as an insulating material. And the hatch itself is sheathed with a sealed rubber sealant tape.