What and how natural foundation is made: all production secrets

Experienced beekeepers know many ways to increase honey yield. In one of them, natural beeswax is used as part of the hives. For such a gift, the bees will say a big "thank you" in the form of a weighty honeycomb filled with fragrant amber honey.

Experienced beekeepers know many ways to increase honey yield. In one of them, natural beeswax is used as part of the hives. For such a gift, the bees will say a big "thank you" in the form of a weighty honeycomb filled with fragrant amber honey.

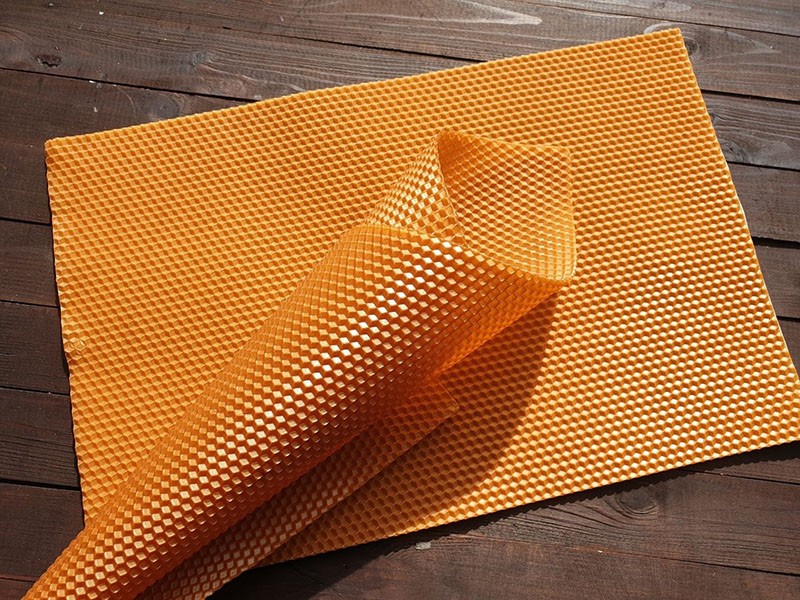

What is natural foundation and what does it look like

A good quality foundation must be able to support the weight of the filled combs and a large number of bees.

The foundation has standard dimensions - 410 by 260 mm regular and 410 by 207 thick. From 1 kg of wax can be made 14-16 plates of regular or 11-13 thickened. By the size of the cell, they are distinguished into bee and drone. The distance between the parallel sides of the bee cell is 5.37 ± 0.03 mm, and that of the drone cell is 6.87 ± 0.04 mm. The size of the angles forming the hexagon is also important. For large southern rocks, honeycombs are suitable, in which adjacent sides converge at an angle of 140 °, for small Central Russian rocks - 120 °. Honeycombs with a mesh angle of 130 ° are considered universal and the most common.

The foundation has standard dimensions - 410 by 260 mm regular and 410 by 207 thick. From 1 kg of wax can be made 14-16 plates of regular or 11-13 thickened. By the size of the cell, they are distinguished into bee and drone. The distance between the parallel sides of the bee cell is 5.37 ± 0.03 mm, and that of the drone cell is 6.87 ± 0.04 mm. The size of the angles forming the hexagon is also important. For large southern rocks, honeycombs are suitable, in which adjacent sides converge at an angle of 140 °, for small Central Russian rocks - 120 °. Honeycombs with a mesh angle of 130 ° are considered universal and the most common.

Why take away work from bees and do foundation yourself

Under natural conditions, bees build their own honeycombs, so why do you need foundation and why do beekeepers spend time making it? The answer is simple - knowledgeable beekeepers simply make the work of their wards easier. The time that the bees would spend on arranging the honeycomb will be spent on collecting nectar and other necessary work in the hive.

Under natural conditions, bees build their own honeycombs, so why do you need foundation and why do beekeepers spend time making it? The answer is simple - knowledgeable beekeepers simply make the work of their wards easier. The time that the bees would spend on arranging the honeycomb will be spent on collecting nectar and other necessary work in the hive.

Experienced beekeepers note that when using foundation:

- the size of the bee's nest increases;

- insects form swarms better in spring;

- the amount of collected honey grows significantly.

Let's find out what the foundation should be made of in order to bees took it for their own and did not reject it.

Poor-quality foundation or its lack leads to untimely swarming and weakness of the bee colony.

Types of foundation

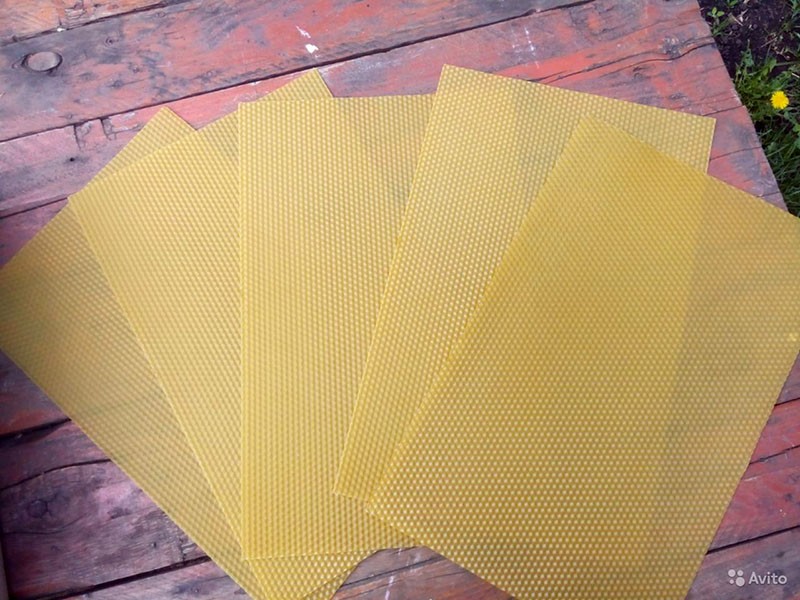

Most beekeepers prefer to deal with natural foundation, since there is no lack of wax in a good apiary. Beeswax is absolutely environmentally friendly, insects consider its smell to be "theirs" and willingly begin to master the new frame.

Most beekeepers prefer to deal with natural foundation, since there is no lack of wax in a good apiary. Beeswax is absolutely environmentally friendly, insects consider its smell to be "theirs" and willingly begin to master the new frame.

In the manufacture of semi-artificial waxes, paraffin and other substitutes are added to the composition. Such plates are less durable, bend worse and begin to melt earlier.

The melting point of natural wax is 62–68 °, of various types of paraffin - from 45 to 65 °. On a hot afternoon, low-melting paraffin honeycomb substitutes can be severely deformed or completely deteriorate.

In retail outlets, you can find artificial foundation made of plastic. It is durable, bends easily, can be stored without problems, the shelf life of artificial foundation reaches 10 years. But beekeepers are in no hurry to use it. Plastic has its own odor, which insects may not like. This problem is solved by covering the plate with a layer of wax. Also, thin plastic breaks easily, and it is impossible to remelt it, unlike wax, at home.

In retail outlets, you can find artificial foundation made of plastic. It is durable, bends easily, can be stored without problems, the shelf life of artificial foundation reaches 10 years. But beekeepers are in no hurry to use it. Plastic has its own odor, which insects may not like. This problem is solved by covering the plate with a layer of wax. Also, thin plastic breaks easily, and it is impossible to remelt it, unlike wax, at home.

Toxic fumes from low-quality material used in the manufacture of artificial foundation can cause the death of an entire bee colony.

How to make natural foundation at home

In the factory, the production of foundation is fully automated. The wax is softened at a certain temperature, the mass is formed into sheets and passed through rollers with a honeycomb pattern.

In the factory, the production of foundation is fully automated. The wax is softened at a certain temperature, the mass is formed into sheets and passed through rollers with a honeycomb pattern.

Novice beekeepers will probably want to know how to make foundation with their own hands. Most often, craftsmen use a simple or electric press, hand rollers.

How to cast a sheet using a press

The simplest and most inexpensive device for processing wax into a plate is a manual press, which is easy to buy or make yourself. It can be made from two metal plates with sides.

The simplest and most inexpensive device for processing wax into a plate is a manual press, which is easy to buy or make yourself. It can be made from two metal plates with sides.

The thickness of the foundation must be at least 4 mm throughout the sheet. Thinner plates will not support the weight of full honeycombs and deform.

To form a cellular surface, silicone matrices with a corresponding profile are attached to both sheets of the press. After laying the dies, it is necessary to check the gap between them. It must be at least 4 mm. Also in the press, it is necessary to provide places for draining excess wax.

To find out how much wax is needed to cast 1 sheet, you should alternately weigh several finished plates of suitable size and quality and find the average value.

The required amount of wax is melted in a water bath and poured onto the lower press plate. The mass is quickly spread over the entire surface with a spatula and covered with a lid. After cooling down, the foundation sheet will be ready.

The electric press is more convenient to use. It is equipped with heating elements that will melt the wax to the desired temperature and prevent it from hardening prematurely.

How to make foundation with hand rolls

The press is good as an inexpensive tool for a small apiaries... For a sprawling honey farm, you will need a more productive device - hand rollers. Working on them resembles spinning the laundry in old washing machines.

The press is good as an inexpensive tool for a small apiaries... For a sprawling honey farm, you will need a more productive device - hand rollers. Working on them resembles spinning the laundry in old washing machines.

Before the first use, the rollers are thoroughly washed, dried and the working surfaces are treated with natural drying oil. The wax is heated and filtered to remove impurities. The refined wax is cast in special molds into sheets of standard size 1.5 cm thick. When the sheets have hardened, they are passed through smooth rollers until the thickness is reduced to 4 mm. The rolled sheets are then passed through engraving rollers.

To prevent the wax from sticking to the engraving rollers, the sheets are wrapped on both sides with cling film. Rolls are installed in front of the rollers on the axles so that they unwind as the mechanism moves.

To avoid smearing the finished surface texture, cold air is blown out of the sheets.

How natural foundation is stored

Finished sheets will last for several years without loss of quality, but storage rules must be observed:

- the foundation is wrapped in paper and folded into a cardboard box or plywood box;

- determined in a cool dry room without foreign odors;

- make sure that stocks are not spoiled by rodents.

Do not think that mice are not interested in wax. Hungry animals are able to gnaw even paraffin candles and laundry soap. A natural product with a honey scent will attract them first.

For storing foundation in winter, a place where the temperature does not drop below 0 ° C is suitable. After a series of frosts, the sheets may bend or crack. The foundation is kept upright within the frames.

The production of natural foundation is a simple and fun process that requires a modest investment and little skill. As a reward for their help in preparing the honeycomb, the bees will certainly thank the caring beekeeper with an excellent harvest of a fragrant and healthy sweet delicacy.