How to build a woodshed with your own hands in a summer cottage

Most owners of suburban real estate, one way or another, are faced with the problem of storing firewood on their site. This publication will describe in detail how to create a convenient do-it-yourself woodshed, schemes and materials suitable for self-erection of a structure will be considered.

Most owners of suburban real estate, one way or another, are faced with the problem of storing firewood on their site. This publication will describe in detail how to create a convenient do-it-yourself woodshed, schemes and materials suitable for self-erection of a structure will be considered.

Read also:do-it-yourself birdhouse drawings and dimensions!

Basic requirements for the design

Despite the simplicity of the design, a number of serious requirements are imposed on this building:

- Protection of fuel supplies from atmospheric precipitation. Based on this requirement, the structure must have a roof and floor that protect the fuel from moisture.

- Free access to firewood. Before building a woodshed with your own hands, study the projects, choose a suitable place for the construction of the building.

- Good ventilation of the interior for proper air circulation in the woodpile.

- The required capacity. The structure should provide the ability to store stocks of firewood, in an amount sufficient for seasonal use.

In addition, the woodshed in the country should have an attractive appearance, for which it is often decorated with decorative trim. The area around the building is planted ivy, decorative grapes.

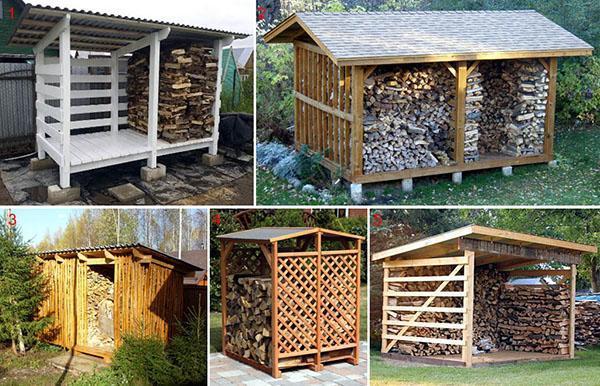

Varieties of woodburners and features of their design

Despite the variety of architectural and design solutions, woodcutters are of two types:

- freestanding;

- attached.

The simplest freestanding woodshed is a canopy on metal support posts without any kind of fencing. A wooden beam serves as a strapping for the roofing. The floor in such structures is most often made of pallets laid directly on the ground or cinder block supports. A more serious option for a firewood is a capital shed for firewood on a foundation with wooden walls in the form of a lattice.

The simplest freestanding woodshed is a canopy on metal support posts without any kind of fencing. A wooden beam serves as a strapping for the roofing. The floor in such structures is most often made of pallets laid directly on the ground or cinder block supports. A more serious option for a firewood is a capital shed for firewood on a foundation with wooden walls in the form of a lattice.

The attached structure can be made in the form of a visor fixed on the wall of a capital building or a full-fledged canopy. The wall of the structure will act as a blank fence.

The attached structure can be made in the form of a visor fixed on the wall of a capital building or a full-fledged canopy. The wall of the structure will act as a blank fence.

Undoubtedly, the second option is much easier to perform, however, it is not recommended to attach firewoods to wooden buildings for two reasons:

- Danger of fire. A firewood is a fuel storage facility. Any spark can ignite the wood, causing a fire.

- Insects that live in abundance in wood, which can quickly destroy a wooden structure, even treated with biosecurity.

If there is no other option, such as an extension of the woodshed to the wooden wall of the house, then experts recommend isolating the surface adjacent to the structure with a steel sheet.

There is one more type of wood logs - mobile. This design is made in the form of a metal stand and is used to store firewood in the room directly near the stove or fireplace.A portable metal woodshed can be a decorative piece of furniture that fits into the overall decor of the room.

There is one more type of wood logs - mobile. This design is made in the form of a metal stand and is used to store firewood in the room directly near the stove or fireplace.A portable metal woodshed can be a decorative piece of furniture that fits into the overall decor of the room.

We build a woodshed with our own hands

Before building a woodshed, the developer will have to answer a number of questions:

- The size of the structure.

- Choosing a place to place the structure.

- The optimal type of wood log.

- Construction design.

- Selection of the necessary materials.

Let's consider the solution of some questions in more detail.

Dimensions and capacity

If the supply of firewood is supposed to be used not for seasonal heating of the house and cooking, but only from time to time to light a fire or barbecue, then very little firewood will be needed. In this case, you can limit yourself to the construction of a free-standing shed or a small shed, which will perform two functions at once: a warehouse and a utility block.

If the supply of firewood is supposed to be used not for seasonal heating of the house and cooking, but only from time to time to light a fire or barbecue, then very little firewood will be needed. In this case, you can limit yourself to the construction of a free-standing shed or a small shed, which will perform two functions at once: a warehouse and a utility block.

If full heating of a country house is planned, then a more voluminous structure should be erected, located not far from the house.

To determine the dimensions of a future building, it is enough to know the amount of fuel consumed.

The second way to determine the woodsman's garabits is the availability of material that is planned to be used for its construction.

Choosing a place on the site

Dimensions, purpose and type of future building will be decisive when choosing the location of the structure:

- If the firewood is planned to be used exclusively for kindling the barbecue, then the best option would be to build a woodshed with a lean-to roof, located in the recreation area, with your own hands.

- As a rule, a building for storing firewood is not an architectural masterpiece, so the best option for placing it is a corner in the backyard of the site.

- When designing such a structure, one should take into account the possibility of a free approach and the presence of a track with a high-quality surface. This will provide access to the woodpile during rain and winter.

- The storage place for firewood should not be located in a low area where moisture accumulates.

- The building will inevitably create shade, which can interfere with the growth of green spaces. Choose a place free of vegetation for the woodpile.

Despite the fact that the firewood or shed is located on its own land and is not qualified by law as a permanent structure, this structure should not be placed, guided only by your own preferences. If the building interferes with the normal use of the adjacent site, neighbors can go to court and demand the elimination of the inconvenience up to the transfer of the building, which is associated with additional financial costs.

Choosing the type of storage and materials to create it

When choosing a woodpile design, most developers start from the budget, comparing it with the desired result. The simplest construction is an attached shed with a floor and three enclosing walls.

When choosing a woodpile design, most developers start from the budget, comparing it with the desired result. The simplest construction is an attached shed with a floor and three enclosing walls.

Attached canopy

First of all, study the legislation, specifically GOST 21.501-93, GOST 21.204-93. Then:

- Draw a sketch. This will allow you to determine the dimensions of the building, the angle of inclination of the roof, the option of joining the roof with the wall of the shed.

- Prepare materials for supporting structure and roofing. Edged board or timber is the optimal material for creating a frame. The wooden batten is suitable for creating a side railing. Sheets of corrugated board, metal tiles, polycarbonate can be used to create a roof.

- Count the materials. For supporting roofs up to 5 m2, pine boards with a section of 100x50 mm can be used. If the roof area exceeds 5m2, then use a bar with a section of 100x100 mm. For all cases, wooden rafters 100x50 (per edge) are used with a crate of 100x25 mm board.

- Provide a foundation, the design of which and the depth of laying depends on the type of soil and the depth of its freezing.

Freestanding polycarbonate woodshed

The design can become not only a functional solution, but also a decoration for your site.

The design can become not only a functional solution, but also a decoration for your site.

The popularity of this material is due to its low cost and good quality characteristics. For the manufacture of the frame, a profiled pipe is used with a section of 40x25 mm. The roof support structure is constructed from a steel strip or metal corner. Polycarbonate is mounted using special fasteners.

Many domestic summer residents are interested in how to make a wood log near a bathhouse? The simplest option is to assemble a metal frame that can be sheathed with sheets of polycarbonate or corrugated board.

When creating an arched roof, the stiffness channels in the sheets of cellular polycarbonate are oriented parallel to the bending line.

Classic woodpile

In some cases, you can limit yourself to the construction of a classic cylindrical woodpile, which copes with the tasks very well.

In some cases, you can limit yourself to the construction of a classic cylindrical woodpile, which copes with the tasks very well.

Next, we'll tell you how to fold a round woodpile:

- We choose a place where water does not accumulate.

- We dig in the pole. Height above ground from 1.5 to 2 m.

- Chocks with a radius of 70 - 80 cm are laid out around the pole.

- Logs are laid out around the perimeter so that one side rests on the chocks laid out in a circle.

- Next, the second row is laid out. Firewood is stacked vertically around the pole, filling the middle of the structure.

- Every 3-4 rows, the process is repeated. Logs as a support are laid out in a circle around the perimeter, on them, chocks. The middle is filled with vertically standing firewood.

A properly assembled structure is durable, spacious, does not spoil the appearance of the site, and the firewood in such a woodpile dries quickly enough.

Pallet woodshed

One of the most budgetary ways to build a storage for a stock of firewood is a pallet firebox.

One of the most budgetary ways to build a storage for a stock of firewood is a pallet firebox.

It is very simple to assemble such a structure:

- Prepare the site.

- Lay out the pallets to act as the floor.

- At the ends, fasten them together with a solid board.

- Use vertical pallets to create the walls.

- Use metal corners to secure them to the base.

- In the front of the structure, install the board on the edge, fixing it between the side walls. It will support pallets that function as a roof.

The last step is to treat the structure with an antifungal compound.

Diy wood firebox: stages of construction

As an example, consider the stages of self-creation of a freestanding wooden structure at a summer cottage. The first thing to do is choose a place to install the structure. The best installation option is an elevation on the site. This arrangement will exclude flooding of the building.

As an example, consider the stages of self-creation of a freestanding wooden structure at a summer cottage. The first thing to do is choose a place to install the structure. The best installation option is an elevation on the site. This arrangement will exclude flooding of the building.

To assemble a firewood for a summer residence with your own hands, drawings are needed.

We present an example of a reliable and spacious design with a pitched roof and the possibility of installing doors to turn a log shed into a permanent shed:

- To create a reliable support structure, we will use metal pipes. To do this, you need to drill holes, as shown in the drawing. The depth is below the freezing point. A layer of rubble is poured at the bottom of each hole. Layer thickness - 100 mm. Pipes are installed in the prepared pits and concreted.

- After the concrete hardens, the upper frame strapping is created. To do this, use a board of 150x50 mm.

- At a height of 100 mm from the ground, a beam with a section of 100x100 mm is attached to the frame, which will be used as a lower strapping and a supporting structure.

- Logs are laid on the timber. For their manufacture, a pine board is used, 100x25 laid on the edge. The distance between the lags is 400 - 500 mm.

- A floorboard is laid on the logs. The best option is lumber with a section of 100x25 mm.

- The frame of the firewood is sheathed with an edged board. Installation is performed with gaps for better ventilation.

- To create a rafter system, lumber with a section of 100x50 mm is used. The lathing is performed with a board with a section of 100x25 mm.

To ensure the protection of firewood from moisture, overhangs must be provided in the roof structure. The minimum overhang length is 300 mm.

After the construction of the building, it is necessary to treat the lumber with an antiseptic. The last question remains: how to paint the woodshed? The correct paint should protect the wood from moisture, UV radiation, protect the material from insects and pathogenic microorganisms (fungi, mold). In addition, a good paint must be abrasion resistant and provide a decorative component over a long period of time. All of the above qualities are possessed by latex paints, which, according to professionals, have practically no drawbacks.