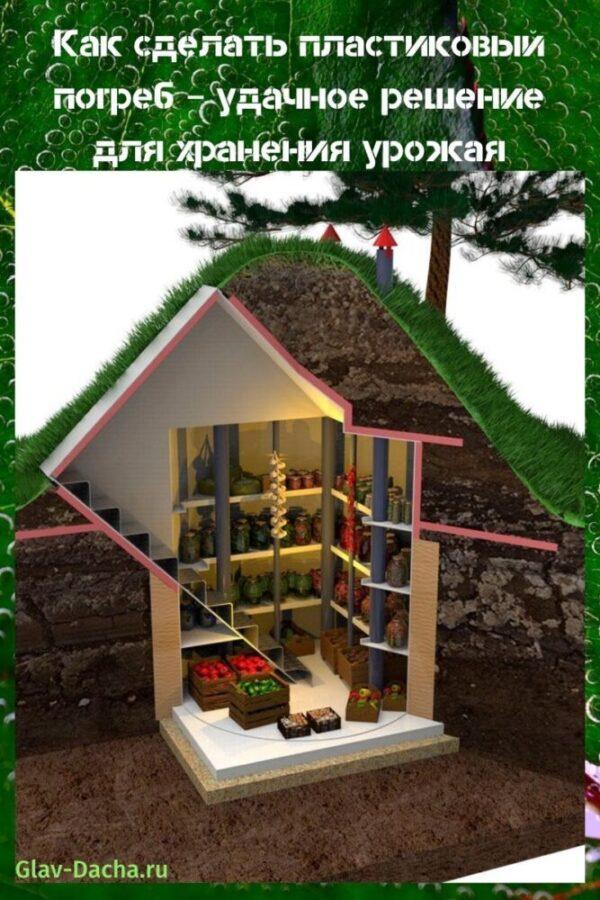

How to make a plastic cellar - a good solution for storing crops

A plastic cellar is a practical and reliable design that can be a good alternative to the traditional brick or concrete storage of crops and conservation. There are several ways how to make a plastic cellar with your own hands and install it under a private house or in another convenient place.

A plastic cellar is a practical and reliable design that can be a good alternative to the traditional brick or concrete storage of crops and conservation. There are several ways how to make a plastic cellar with your own hands and install it under a private house or in another convenient place.

What is a plastic cellar

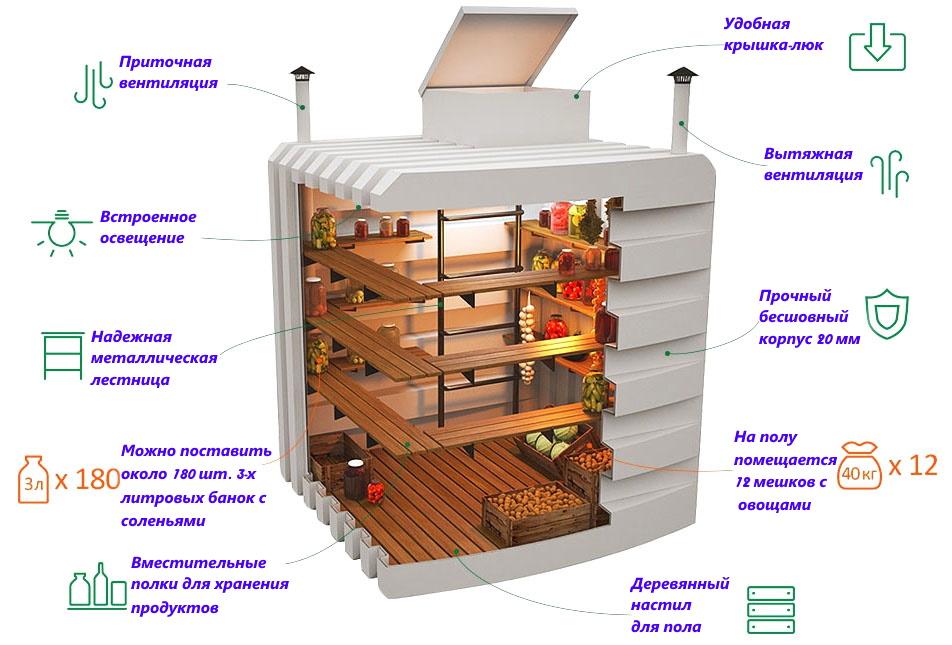

Ready-made plastic cellars are sold with all accessories:

- structure frame;

- sealed cover;

- steps;

- neck;

- shelves;

- crop storage spaces;

- ventilation system.

A plastic cellar in the country can be either traditionally rectangular or cylindrical, with a rounded structure. The second design is less common, but has its advantages. Its installation is much easier and cheaper than a cubic cellar.

A cylindrical plastic cellar is great for high groundwater and clayey soils.

Design advantages and disadvantages

Before you make your own plastic cellar, you need to familiarize yourself with the main advantages and disadvantages of this design.

Before you make your own plastic cellar, you need to familiarize yourself with the main advantages and disadvantages of this design.

Pluses of the caisson:

- The caisson can be placed anywhere, regardless of the height of the water table, soil type and other factors that often make it difficult to build a traditional storage facility.

- Installation of a plastic cellar is possible not only in an open area, but also under a house or other building.

- A construction made of plastic or fiberglass perfectly tolerates a high level of soil water, sudden changes in temperature. With the correct installation of the caisson, the quality of storage of vegetables and fruits is significantly improved.

- The walls of the plastic storage are reliably protected from insects and rodents, fungi, and mold. This material does not absorb odors; if necessary, it can be easily washed and disinfected.

- Such structures have a long service life - up to 40-50 years.

The main problems of plastic cellars are associated with their high cost and standard parameters. The price of the finished structure is 30-50% higher than the cost of building an ordinary cellar.

The standard parameters of the caisson can become a problem if a pit has already been prepared at the dacha for a cellar of a larger or smaller size. But these disadvantages are offset by the reliability, versatility and durability of the plastic construction.

The standard parameters of the caisson can become a problem if a pit has already been prepared at the dacha for a cellar of a larger or smaller size. But these disadvantages are offset by the reliability, versatility and durability of the plastic construction.

Varieties of ready-made cellars

Manufacturers offer various types of plastic cellars. Depending on the type of assembly, they can be solid (seamless) or collapsible. The shapes of such structures also differ - there are rectangular, round, cylindrical caissons on the market.

Manufacturers offer various types of plastic cellars. Depending on the type of assembly, they can be solid (seamless) or collapsible. The shapes of such structures also differ - there are rectangular, round, cylindrical caissons on the market.

The most popular and versatile is a seamless caisson - outwardly, this design looks like a tin can with a lid.Such a product can easily withstand sudden temperature changes and a high level of groundwater, protects the stored crop from fungi, mold and other microorganisms, as well as insects.

The most popular and versatile is a seamless caisson - outwardly, this design looks like a tin can with a lid.Such a product can easily withstand sudden temperature changes and a high level of groundwater, protects the stored crop from fungi, mold and other microorganisms, as well as insects.

All types of plastic cellars differ in the complexity of installation. Seamless caissons are much easier and faster to install, but they are expensive. Dismountable products are slightly cheaper, but require preliminary assembly, so installation is more difficult.

All types of plastic cellars differ in the complexity of installation. Seamless caissons are much easier and faster to install, but they are expensive. Dismountable products are slightly cheaper, but require preliminary assembly, so installation is more difficult.

Design selection rules

It is very difficult to choose a plastic cellar without knowing the basic design features, especially for a novice summer resident.

It is very difficult to choose a plastic cellar without knowing the basic design features, especially for a novice summer resident.

Therefore, you need to take into account several useful recommendations of specialists.:

- First of all, it is necessary to clarify what kind of plastic the caisson is made of. It must be environmentally friendly so as not to harm the stored food and human health.

- A plastic cellar should be bought only in specialized stores - before buying, you must make sure that you have all the quality certificates and manufacturer's guarantees. This will save you from unpleasant problems after installation.

- All types of plastic caissons are equipped with built-in standard ventilation systems. They are great for storing canned food and other foods, but vegetables and fruits release increased moisture. A standard air exchange system may not cope with this problem, so it is advisable to choose cellar models with built-in hoods.

For regions with a cold climate and sharp temperature changes, it is best to choose plastic caissons with insulated walls.

If desired, the walls of the cellar can be insulated on their own using foam or other materials. This will ensure the reliable preservation of crops and other products.

How to make a plastic cellar with your own hands: basic installation rules

It is impossible to make a plastic cellar with your own hands, since such structures are made using complex industrial equipment, using special technology. But the installation of a finished cellar is within the power of every owner.

It is impossible to make a plastic cellar with your own hands, since such structures are made using complex industrial equipment, using special technology. But the installation of a finished cellar is within the power of every owner.

After buying a structure, many summer residents are faced with the fact that they do not know how to install it. Installation errors lead to the fact that the tightness of the cellar is broken or high groundwater pushes it to the surface. That is why it is necessary to take into account all the nuances of the installation, and it is better to first draw a drawing and draw up an action plan, which consists of several stages.

Preparation of the pit

Before you make your own plastic cellar, you need to prepare a pit. It can be dug with your own hands or with the help of an excavator or front loader.

Before you make your own plastic cellar, you need to prepare a pit. It can be dug with your own hands or with the help of an excavator or front loader.

The size of the pit should correspond to the dimensions of the plastic cellar, but it is imperative to leave a gap of about 50 cm around the perimeter. When calculating the depth of the pit, one should take into account the thickness of the pillow at the bottom, under the caisson.

At the bottom of the dug hole, you need to fill in a sand cushion up to 8-11 cm thick, and on top lay a reinforcing mesh made of steel rods with a diameter of 13-15 mm. After that, you should take care of the base for the plastic caisson. The best option is concrete, so the reinforcement must be poured with a layer concrete up to 9-10 mm.

At the bottom of the dug hole, you need to fill in a sand cushion up to 8-11 cm thick, and on top lay a reinforcing mesh made of steel rods with a diameter of 13-15 mm. After that, you should take care of the base for the plastic caisson. The best option is concrete, so the reinforcement must be poured with a layer concrete up to 9-10 mm.

Caisson installation

After preparing the pit and the concrete base, you can begin the installation of the plastic cellar. The structure must be installed strictly vertically. In the remaining gap between the plastic wall and the soil, you should fill in the soil that was dug when digging the hole. Backfilling must be carried out in layers along the entire perimeter with simultaneous compaction. Care must be taken to ensure that the plastic structure does not move or tilt.

After preparing the pit and the concrete base, you can begin the installation of the plastic cellar. The structure must be installed strictly vertically. In the remaining gap between the plastic wall and the soil, you should fill in the soil that was dug when digging the hole. Backfilling must be carried out in layers along the entire perimeter with simultaneous compaction. Care must be taken to ensure that the plastic structure does not move or tilt.

The upper half of the cellar can be installed in two ways:

- The top hatch lines up with the floor line.There is a gap between the plastic and the floor, which should be covered with sand (earth, foam or other insulation) to the required level. Then level the outer covering that was before digging the hole.

- The neck of the cellar protrudes above the surface. In this case, it is imperative to lay a shock-absorbing layer, consisting of rolled insulation and the finishing floor is laid.

At the final stage of the installation of the plastic cellar, the caisson is fixed with special slings. To create an optimal microclimate inside the storage, at the end of installation, it should be covered with soil.

At the final stage of the installation of the plastic cellar, the caisson is fixed with special slings. To create an optimal microclimate inside the storage, at the end of installation, it should be covered with soil.

After that, the installation is carried out ventilation system and supplying power to the lighting and fan. If the ready-made cellar for high groundwater does not have an automatic input switch in the kit, it is necessary to mount an electrical panel with appropriate devices equipped with an RCD.

After that, the installation is carried out ventilation system and supplying power to the lighting and fan. If the ready-made cellar for high groundwater does not have an automatic input switch in the kit, it is necessary to mount an electrical panel with appropriate devices equipped with an RCD.

A plastic cellar is a convenient and practical design. It can be a great alternative to traditional brick and concrete storage facilities. The advantages of such products are considered versatility, exceptional resistance to high groundwater and temperature extremes. And also a long service life.  The only drawbacks of the cellar are the high cost and the need to dig a pit to fit the dimensions of the finished plastic structure.

The only drawbacks of the cellar are the high cost and the need to dig a pit to fit the dimensions of the finished plastic structure.