Useful information for beekeepers: how to make a wax melter with your own hands quickly and cheaply

One of the most valuable beekeeping products is wax. How to make a wax melter with your own hands in order to obtain a high-quality substance from raw materials on your own? This issue is considered by many beekeepers, and all possible options are evaluated by them from a practical point of view. There are several simple solutions for the processing of wax raw materials, with the help of which you can establish wax production in an apiary.

One of the most valuable beekeeping products is wax. How to make a wax melter with your own hands in order to obtain a high-quality substance from raw materials on your own? This issue is considered by many beekeepers, and all possible options are evaluated by them from a practical point of view. There are several simple solutions for the processing of wax raw materials, with the help of which you can establish wax production in an apiary.

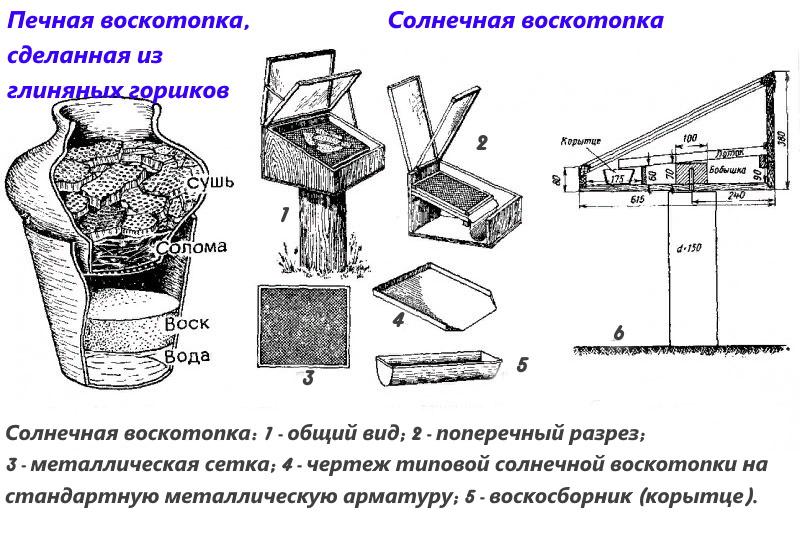

How to make a wax melter with your own hands: the principles of the main models

The moisture content of raw materials depends on the content of non-wax impurities in it - cocoons, bee bread, honey residues. If it exceeds 10%, the raw material becomes moldy, its temperature gradually rises.

Many beekeepers in our country know how to make wax pots with their own hands. They choose a suitable design, the use of which will bring them considerable benefits. Even a person who first encountered this problem can analyze the basic designs presented below and make a device on their own.

Solar wax melter: advantages and disadvantages

One of the main conditions for using this wax melting plant is the high wax content of the feedstock. Getting wax in this way is quite simple as the costs are minimal. No resource consumption, no additional power supplies are needed.

One of the main conditions for using this wax melting plant is the high wax content of the feedstock. Getting wax in this way is quite simple as the costs are minimal. No resource consumption, no additional power supplies are needed.

The solar wax melter has many advantages:

- uncomplicated design;

- compactness;

- mobility;

- the possibility of making from scrap materials.

The work of the solar wax melter does not need to be constantly monitored, it is completely safe. Its performance is quite sufficient for full-fledged maintenance of a small apiary.

But the biggest advantage of this device is its simple design. Even a person who is ignorant of construction and carpentry can easily figure out how to make a wax melter himself.

The principle of operation is as follows:

- Frames with honeycomb fixed inside the case.

- The wax melting pot is placed in an open place well-lit by the sun. Turn or move during the day.

- The sun's rays pass through the glass, due to this, the intensity of heating the honeycomb increases.

- The molten substance gradually flows into the installed reservoir, through a fine-mesh mesh, on the surface of which all the debris in the frame remains.

The resulting wax does not need to be processed additionally, since at the exit it turns out clean, without impurities. Gloves should be used in contact with the case, it can be very hot.

But, at the same time, the solar wax melter has disadvantages. In the event of a cold and humid summer, with frequent rains and prevailing cloudy weather, the device will not be useful. Even if the summer season turns out to be dry and hot, one structure is enough to serve only 50 colonies of bees. On apiaries with a large number of hives, for quick extraction of wax, several wax pots should be installed at once.

You can improve device performance in several ways:

- paint the inner surface with black paint;

- choose the best angle of inclination of the upper part of the structure;

- install glass with suitable optical properties.

If you use solar reflectors on the back to speed up the process, the output will be dark.

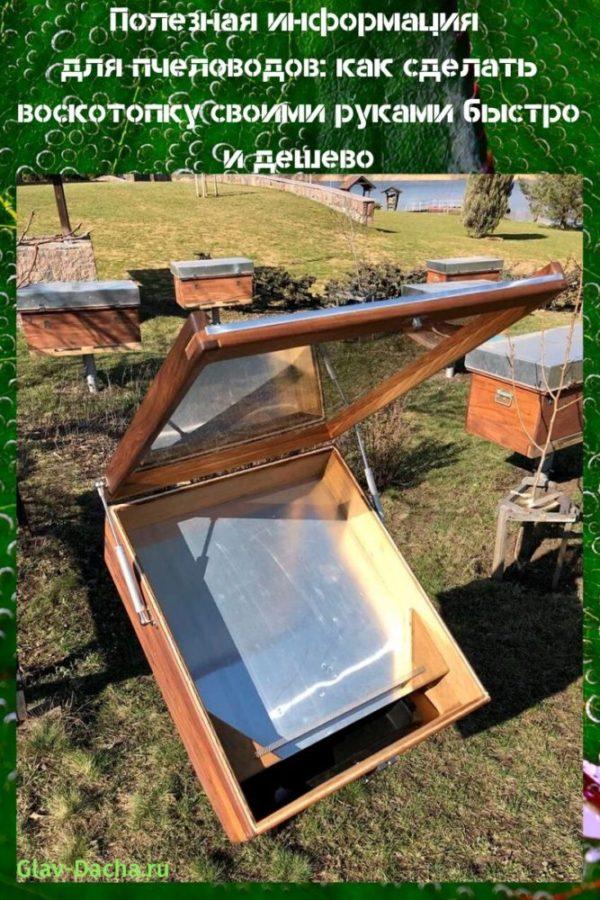

How to make a solar wax melter with your own hands according to drawings

To make this simple device, consisting of a beveled box, plywood bottom and glass lid, you do not have to purchase a lot of materials and accessories. Most of the essentials are in every household farm or in the country.

To make this simple device, consisting of a beveled box, plywood bottom and glass lid, you do not have to purchase a lot of materials and accessories. Most of the essentials are in every household farm or in the country.

For work you will need:

- penoplex, boards of small thickness, plywood for the body;

- glass;

- hammer;

- screwdriver;

- galvanized sheet;

- consumables - nails, screws, screws, hinges.

The sizes of solar wax pans vary. When self-manufacturing, you can focus on the dimensions of a standard product of 500 mm x 580 mm. Its height is within 270 mm. The glass must be 580 mm x 568 mm. In order to extend the life of the product, all materials used (except glass) are painted with safe compounds.

If the body is made of metal, its heating will increase, and, consequently, the wax heating process will go faster. But working with such a wax melter will be more difficult.

Before proceeding, mark out the body parts. Cut rectangles 580 mm x 270 mm (back wall), 500 mm x 580 mm (plywood bottom), two trapezoidal side parts 500 mm x 270 mm x 80 mm.

Phased execution:

- Details are cut and fastened together.

- The walls are reinforced with bars or fixed on a metal frame.

- Glass lid hinges are attached to the top of the back wall.

- Make a frame for glass and install on the body.

- A metal tray with curved edges and drain holes at the bottom, closed with a fine mesh, is installed inside.

The build quality is checked and assessed, after which the structure is covered with a layer of dark paint.

To preserve the quality of the finished product and prevent the ingress of dust particles, the wax melter is installed on a support or pillar. Provision should be made for fixing the glass frame in the open and closed position.

Do-it-yourself steam wax melter: device drawings

Melting wax with steam is often used by beekeepers. This method is quite effective, since the percentage of its yield depends on the duration of processing. When processed with steam, the raw materials gradually soften, the wax contained in it turns into a liquid state. Suitable for use are old honeycombs left after distilling honey, waxes and any bee waste products containing wax.

Melting wax with steam is often used by beekeepers. This method is quite effective, since the percentage of its yield depends on the duration of processing. When processed with steam, the raw materials gradually soften, the wax contained in it turns into a liquid state. Suitable for use are old honeycombs left after distilling honey, waxes and any bee waste products containing wax.

When melting wax with steam, the wax has no contact with water, so no emulsion is formed. Its composition remains as useful as possible.

Household juicers and steamers are often used as a steam wax melter. Devices are often purchased or made in-house. How to make a steam wax refinery with your own hands so that the costs are low and the return is quite satisfactory? Round-shaped models have proven themselves better than others, since it is not difficult to choose a container in this case. An old tall saucepan, a milk canister, or even a gas bottle will do.

Parts and parts of the steam wax melter:

- reliable case;

- steam generator;

- container for frames;

- a pallet onto which the wax should flow.

One of the easiest wax pots to make is a device - a barrel about водой filled with water, or a pan installed on a heat source. At the bottom there should be a support holding the stainless steel basin above the water. Above the container, wax raw materials are suspended, placed in a special basket made of stainless mesh. The tank is tightly closed with a lid.

When the water boils, hot steam envelops the basket. The wax in the raw material begins to melt and drain into the basin. Everything happens pretty quickly, so you need to make sure that the container for collecting wax does not overflow.

When the water boils, hot steam envelops the basket. The wax in the raw material begins to melt and drain into the basin. Everything happens pretty quickly, so you need to make sure that the container for collecting wax does not overflow.

For the manufacture of a frame wax pot, suitable drawings and improvised means are used:

- you will need 2 rectangular stainless steel tanks - an internal one with a mesh bottom, frames are placed in it;

- a baking sheet is installed under the inner tank, tapering to the outlet through which the wax flows;

- the structure is covered with a lid that ensures sufficient heating of the frames.

The steam source can be located at a distance from the loading chamber and connected to it with a hose.

Summing up

Making a wax melter at home is based on the methods of thermal processing of wax raw materials - dry and wet, pressing. In apiaries, various heat carriers are used, including the energy of the sun, hot steam.

Making a wax melter at home is based on the methods of thermal processing of wax raw materials - dry and wet, pressing. In apiaries, various heat carriers are used, including the energy of the sun, hot steam.

The wax obtained in the apiary must be cleaned and clarified. It is melted again, filtered through a special cloth and defended for five hours. These processes must take place at a temperature of at least 70 ° C.

To cleanse wax from chemical contaminants, solutions of many acids, including citric and acetic acids, are used.