Working with a megohmmeter: principles and features

All electrical installations and systems in operation require mandatory electrical measurements in order to determine the general condition, safety and performance of electrical networks, including checking the insulation resistance parameters. For these measurements, you will need to work with a megohmmeter, a device designed to timely detect insulation defects. To use a megohmmeter, it is necessary to study its technical characteristics, principle of operation, device and specific features.

All electrical installations and systems in operation require mandatory electrical measurements in order to determine the general condition, safety and performance of electrical networks, including checking the insulation resistance parameters. For these measurements, you will need to work with a megohmmeter, a device designed to timely detect insulation defects. To use a megohmmeter, it is necessary to study its technical characteristics, principle of operation, device and specific features.

Megohmmeter device

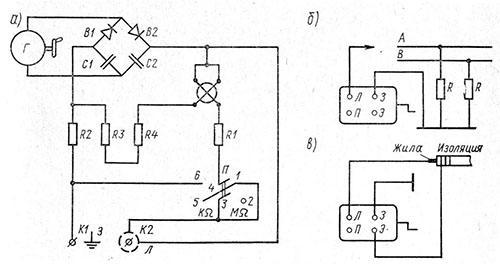

Regardless of the type, the megohmmeter device consists of the following elements:

- voltage source;

- ammeter with instrument scale;

- probes, with the help of which the voltage from the megohmmeter is transferred to the measured object.

Working with a megohmmeter is possible thanks to Ohm's law: I = U / R. The device measures the electric current between two connected objects (for example, 2 cores of a wire, core-ground). The measurements are carried out with a calibrated voltage: taking into account the known values of current and voltage, the device determines the insulation resistance.

Most models of megohmmeters have 3 output terminals: ground (Z), line (L); screen (E). Terminals З and Л are used for all measurements of the device, E is intended for measurements between two similar live parts.

Types of megohmmeters

There are two types of megohmmeters on the market today: analog and digital:

- Analog (pointer megohmmeter). The main feature of the device is the built-in generator (dynamo), which is started by turning the handle. Analog instruments are equipped with a scale with an arrow. Insulation resistance is measured by magnetoelectric action. The arrow is fixed on an axle with a frame coil, which is acted upon by the field of a permanent magnet. When the current moves along the frame coil, the arrow is deflected by an angle, the value of which depends on the strength and voltage. The indicated type of measurement is possible due to the laws of electromagnetic induction. The advantages of analog devices include their simplicity and reliability, the disadvantages are their large weight and considerable dimensions.

- Digital (electronic megohmmeter). The most common type of meters. Equipped with a powerful pulse generator using field effect transistors. Such devices convert alternating current into direct current, the source of current can be a battery or a network. The measurements themselves are carried out by comparing the voltage drop in the circuit with the reference resistance using an amplifier. The measurement results are displayed on the device screen. In modern models, the function of storing the results in memory for further data comparison is provided. Unlike an analog megohmmeter, an electronic one has a compact size and low weight.

Working with a megohmmeter

To work with the device, you need to know how to measure the insulation resistance with a megohmmeter.

To work with the device, you need to know how to measure the insulation resistance with a megohmmeter.

The whole process can be conditionally divided into 3 stages.

Preparatory. During this stage, it is necessary to make sure of the qualifications of the performers (specialists with an electrical safety group of at least 3 are allowed to work with the megohmmeter), solve other organizational issues, study the electrical circuit and turn off the electrical equipment, prepare devices and protective equipment.

Main. Within the framework of this stage, in order to correctly and safely measure the insulation resistance, the following procedure for working with a megohmmeter is provided:

- Measurement of insulation resistance of connecting wires. The specified value must not exceed the Upper Range Value (Upper Range) of the device.

- Setting the measurement limit. If the resistance value is unknown, the highest limit is set.

- Checking the object for lack of voltage.

- Disconnection of semiconductor devices, capacitors, all parts with reduced insulation.

- Grounding of the tested circuit.

- Fixation of instrument readings after a minute of measurements.

- Taking readings when measuring objects with a large capacity (for example, long wires) after stabilization of the arrow.

- Removal of the accumulated charge by grounding at the end of measurements, but before disconnecting the ends of the megohmmeter.

Final. At this stage, the equipment is prepared for power supply and the documentation for the measurements is drawn up.

Before starting measurements, you must make sure that the device is working properly!

There is a way how to check the megohmmeter for serviceability. It is necessary to connect wires to the terminals of the device and short the output ends. Then voltage is required and the results must be monitored. A working megohmmeter shows the result "0" when measuring a short circuit. Then the ends are disconnected and repeated measurements are taken. The display should show the value "∞". This is the value of the insulation resistance of the air gap between the outlet ends of the device. Based on the values of these measurements, it is possible to draw a conclusion about the readiness of the device for operation and its serviceability.

Safety rules when working with a megohmmeter

Before starting work with a resistance meter, you must familiarize yourself with safety precautions when using a megohmmeter.

Before starting work with a resistance meter, you must familiarize yourself with safety precautions when using a megohmmeter.

There are a number of basic rules:

- The probes should be held exclusively by insulated areas bounded by stops;

- Before connecting the megohmmeter, it is important to make sure that there is no voltage on the device and that there are no strangers in the work area.

- It is necessary to remove the residual voltage by touching the portable grounding of the measured circuit. The ground must not be disconnected before installing the probes.

- All work with a megohmmeter according to the new rules is carried out in protective dielectric gloves.

- After each measurement, it is recommended to connect the test leads to relieve residual voltage.

To perform work with a megohmmeter in electrical installations, the device must undergo appropriate tests and be verified.

Measurement of insulation resistance of wires and cables

A megohmmeter is often used to measure the resistance of cable products. Even for novice electricians, with the ability to use the device, it will not be difficult to check a single-core cable. Checking a multicore cable is time consuming, since measurements are taken for each core. In this case, the remaining veins are combined into a bundle.

A megohmmeter is often used to measure the resistance of cable products. Even for novice electricians, with the ability to use the device, it will not be difficult to check a single-core cable. Checking a multicore cable is time consuming, since measurements are taken for each core. In this case, the remaining veins are combined into a bundle.

If the cable is already in use, before starting to measure the insulation resistance, it must be disconnected from the power supply and the load connected to it must be removed.

The control voltage when the cable is dialed with a megger depends on the voltage of the network in which the cable is used. For example, if the wire operates at 220 or 380 volts, then for measurements it is necessary to set the voltage to 1000 volts.

To perform measurements, one probe must be connected to the cable core, the other to the armor, and then apply voltage. If the measurement value is less than 500 kΩ, then the wire insulation is damaged.

Insulation resistance test of the electric motor

Before proceeding to check the electric motor with a megohmmeter, it must be de-energized. To carry out work, it is necessary to provide access to the terminals of the windings. If the operating voltage of the electric motor is 1000 volts, it is worth setting 500 volts for measurements. For measurements, one probe must be connected to the motor housing, the other one in turn to each terminal. To check the connection of the windings to each other, the probes are installed simultaneously on a pair of windings. Contact should be with metal without traces of paint and rust.

Before proceeding to check the electric motor with a megohmmeter, it must be de-energized. To carry out work, it is necessary to provide access to the terminals of the windings. If the operating voltage of the electric motor is 1000 volts, it is worth setting 500 volts for measurements. For measurements, one probe must be connected to the motor housing, the other one in turn to each terminal. To check the connection of the windings to each other, the probes are installed simultaneously on a pair of windings. Contact should be with metal without traces of paint and rust.

This article is for informational purposes only. More detailed and accurate information is contained in the instructions for the use of megohmmeters, technical and regulatory documents.