Why and how the chainsaw carburetor is adjusted

The internal combustion engine works by burning a premixed mixture of air, oil and gasoline. Chainsaw carburetor adjustment is needed to prepare the mixture in the required proportion. It depends on the operation of the carburetor whether the engine will run at the declared power or stall.

The internal combustion engine works by burning a premixed mixture of air, oil and gasoline. Chainsaw carburetor adjustment is needed to prepare the mixture in the required proportion. It depends on the operation of the carburetor whether the engine will run at the declared power or stall.

How the carburetor works

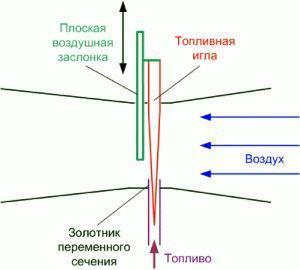

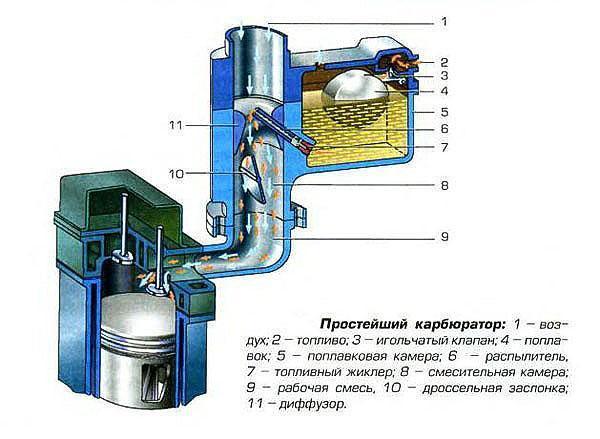

- constricted air tube;

- fuel supply system;

- regulating air damper.

Air at atmospheric pressure, passing through the air cleaner, is supplied to the narrowing zone, where its flow rate is regulated by a flat damper overlapping the section. After narrowing, a vacuum occurs in the pipe. As a result, the vacuum sucks in fuel from the fuel supply tube, the exit from which is regulated by a fuel needle connected to the float chamber by a jet. The device of a chainsaw carburetor is, in principle, no different from other fuel mixers of internal combustion engines.

The mixing principle is to regulate the air damper, float level, depending on the degree of vacuum. We open the air - more fuel comes in, the engine rises. The correct mixture ratio depends on the precise adjustment of the chainsaw carburetor. If there is a lot of air in the fuel, the power drops, the mixture is called lean. With a lack of air, there is a large fuel consumption, incomplete combustion, carbon deposits on the cylinder and exhaust of unburned fuel. This says the mixture is oversaturated.

The mixing principle is to regulate the air damper, float level, depending on the degree of vacuum. We open the air - more fuel comes in, the engine rises. The correct mixture ratio depends on the precise adjustment of the chainsaw carburetor. If there is a lot of air in the fuel, the power drops, the mixture is called lean. With a lack of air, there is a large fuel consumption, incomplete combustion, carbon deposits on the cylinder and exhaust of unburned fuel. This says the mixture is oversaturated.

Chainsaw Ural according to the instructions, requires running-in with the use of an enriched fuel mixture. Therefore, the carburetor comes from the factory with the setting for the run-in period. When switching to the operating mode, the node is reconfigured.

Signs of good chainsaw carburetor performance:

- the engine runs smoothly, sounding like a four-stroke;

- fast set of revolutions;

- the chain does not spin at idle.

When carburetor adjustment is required

The new chainsaw is adjusted to the recommended mix. All you need to do is fine-tuning with three screws; you don't need to disassemble the carburetor. The purpose of the adjusting screws:

The new chainsaw is adjusted to the recommended mix. All you need to do is fine-tuning with three screws; you don't need to disassemble the carburetor. The purpose of the adjusting screws:

- "L" regulates the fuel supply at low rpm;

- "H" is needed to regulate the maximum fuel supply;

- "T" idle speed control.

Since the carburetor of the saw is adjusted by ear with the engine running, safety measures must be observed. The saw should be positioned securely with the cutters pointed in a safe direction.

Before starting the manipulation, it is necessary to mark the initial position of the screws with paint or felt-tip pen. The exact values for setting the carburetor of the chainsaw for each model are in the instruction manual.

However, more often, a carburetor tincture is required after the instrument malfunction has been eliminated. The reasons may be:

- violation of the protective cap and imbalance of the screws;

- engine piston wear, requiring a different mixture to work;

- unsatisfactory operation of the carburetor itself.

How to adjust the carburetor to chainsaw specific model? Perform operations sequentially, guided by the instructions. Here is the algorithm, the general sequence of actions.

There are two stages of tuning:

- basic, with the engine off;

- thin - on a warm engine, idling.

The basic setting is only for the low and high speed fuel screws. Smoothly, without haste, you should completely close the flaps to the stop. Also slowly open both screws counterclockwise by 1.5 turns. Then start the engine and warm it up for 10 minutes.

The basic setting is only for the low and high speed fuel screws. Smoothly, without haste, you should completely close the flaps to the stop. Also slowly open both screws counterclockwise by 1.5 turns. Then start the engine and warm it up for 10 minutes.

How to adjust the carburetor on a chainsaw with the engine running:

- adjust the idle speed with the screw "T", turning counterclockwise until the engine runs at idle speed;

- check the speed of the set of revolutions, with slow unwinding, turn the screw L an additional 1/8 turn;

- set the highest rotation speed on the tachometer with screw H;

- check the idling of the carburetor completely.

How to find a faulty carburetor

However, the adjustment may be preceded by the repair of the carburetor itself, when it cannot fulfill its function as a fuel mixer.

However, the adjustment may be preceded by the repair of the carburetor itself, when it cannot fulfill its function as a fuel mixer.

If fuel for some reason does not enter the engine, check the condition of the fuel supply unit. Often the reason is the supply of low-quality gasoline, as a result, the fuel passages are clogged.

If the fuel mixture has stood for a long time, the additives have collapsed, the mixture can clog the passages and grate with sediment. In this case, a lengthy flushing is required, which is done with solvents in a service workshop.

Troubleshooting yourself

If the troubleshooting is done by hand, it is necessary to free up space and expand the small parts. Tool required:

- brush;

- screwdriver for cross-threaded heads;

- socket wrench or head M6;

- pure gasoline.

The main thing is to properly release the unit from the installation site, cleaning it from the outside from dirt. The air intake is removed, opening access to the carburetor and the suction draft. Remove the throttle lever by lowering the carburetor choke. Release the part by removing the choke lever, lifting the wire along with the lever towards you, picking it up on the left.

The main thing is to properly release the unit from the installation site, cleaning it from the outside from dirt. The air intake is removed, opening access to the carburetor and the suction draft. Remove the throttle lever by lowering the carburetor choke. Release the part by removing the choke lever, lifting the wire along with the lever towards you, picking it up on the left.

Rinse the freed carburetor in gasoline, blow through with air, clean the grate by injecting with a thin needle.

When reassembling the assembly, make sure that the spring under the needle lever is in place. If you forget it, the fuel is not cut off, the candle is damp and does not give a spark.

It happens on saw Calm the gas key slightly wedges. In this case, the throttle must be cleaned of plaque. It is necessary to protect the damper with tinning after cleaning.

After assembling the carburetor, setting it in place, adjust it as described above.

Thank you for the article ! and videos with good comments. I really liked it and it was useful for me.

Hello. I have a used saw Lider 4500. I washed the carbirater. I turned the setting. L H how to stand now. Thank you

thank you

I have a BP-18/2700 Optima saw Unscrew the screws by 1.5 turns Set the tachometer to idle 3000 maximum 12000 starts well picks up speed well but ……. After sawing 3 good logs it stalls. stops starting. After it cools down, I check all the adjustments, I start the saw and again everything is repeated and so endlessly Help please

The new saw almost did not work, I bought it a year ago and since then I have been trying to cut but to no avail