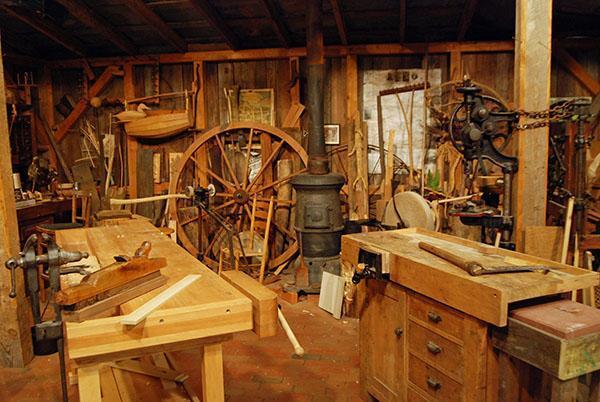

We equip a home workshop with woodworking machines

In the workshop, a wide variety of tools, machines and systems are used to work with wood products. Some woodworking machines for the home workshop are used very often, while others are designed to perform only some specific highly specialized work. It should be noted that working with wood at home is very different from working in a woodworking or carpentry workshop.

In the workshop, a wide variety of tools, machines and systems are used to work with wood products. Some woodworking machines for the home workshop are used very often, while others are designed to perform only some specific highly specialized work. It should be noted that working with wood at home is very different from working in a woodworking or carpentry workshop.

Grinding machine

Grinding machines are used to give a wooden product, or rather its surface, to perfect smoothness. What machines can be used to process not only new products. The wood grinding machine allows you to re-process wood parts that are already ready or even used in everyday life, which have become unusable during operation or have lost the smoothness of the surface.

Grinding machines are used to give a wooden product, or rather its surface, to perfect smoothness. What machines can be used to process not only new products. The wood grinding machine allows you to re-process wood parts that are already ready or even used in everyday life, which have become unusable during operation or have lost the smoothness of the surface.

Depending on the functional purpose and design features, such devices are divided into:

- tape type;

- vibrating;

- corner;

- disc-shaped (orbital);

- brush-grinding;

- combined.

While all of these machines have different designs and process material in different ways, they all have the same purpose - to give the surface of a wooden product a perfectly smooth look. It is worth noting that industrial wood processing machines have many more varieties than those used at home. Moreover, the functionality of industrial devices is much wider, and their capabilities far exceed those of devices that can be used in home workshops.

At home, mini-machines for grinding wood are most often used. When processing small parts, their functionality is sufficient.

Sawing machine

A sawing machine is a machine that allows you to cut wood or parts in a straight line. In homemade woodworking workshops, machines with a disc cutting element are most often chosen.

A sawing machine is a machine that allows you to cut wood or parts in a straight line. In homemade woodworking workshops, machines with a disc cutting element are most often chosen.  However, depending on the features of the main cutting element, the equipment for sawing is divided into types:

However, depending on the features of the main cutting element, the equipment for sawing is divided into types:

- Disk. This is equipment that has a flat work surface and a circular saw. During operation, the wooden element is fed onto the disc along the bed. The disc cuts the material so thinly and evenly that there are no chips, delamination, and so on.

- Striped. In such an apparatus, the cutting process is performed by a strip saw. However, in home workshops, such woodworking machines are used very rarely, since they are very voluminous and cumbersome. They are more commonly used in industrial sawmills.

- With flexible saw. Such equipment can have different saws (band, wire rope or chain saw). In industrial conditions, only tape is used, however, for work at home, you can choose any of the above. The device of this type cuts the material quickly enough, quietly, and the speed of work on such a device exceeds the speed of work on a disk.

Working on such a machine, it is necessary to adhere to all safety rules, since all cutting elements are very sharp and dangerous!

Circular machine

Circular saws have some similarities with sawing equipment. The purposes of the circular wood machine are:

Circular saws have some similarities with sawing equipment. The purposes of the circular wood machine are:

- Dissolving lumber both along and across.

- Manufacturing of wooden beams.

- Saw plywood.

- Manufacturing of glazing beads.

A circular saw is a woodworking machine that can be made by hand.

By design, circular saws can be divided into three categories:

- Tabletop. Used in a domestic environment. The weight of such a machine varies up to 25 kg. You can install such a device on any work surface, for example, on a table.

- With a stand. This machine is also portable, but it is equipped with a special stand that allows you to handle long boards.

- Stationary. Most often, such woodworking machines are used in industrial production. It is stationarity, that is, the immobility and stability of the structure, that allows you to perform work on such an apparatus very accurately and efficiently.

For all of the above circular saws, different cutting blades must be selected.

Thicknesser

The main purpose of the wood thicknessing machine is to smooth the surface of the wood element. In addition, such machines are used in order to calibrate all the same type of product to the same size.

The main purpose of the wood thicknessing machine is to smooth the surface of the wood element. In addition, such machines are used in order to calibrate all the same type of product to the same size.

The design of the various installations allows for cutting both along the wood and across.

The device has a work surface in the form of a table. It consists of 2 parts. One of them supplies the wooden element and the other receives it. Between these surfaces there is a special shaft in the form of a knife, which is used for cutting. After cutting, the wooden element goes to the receiving table. In this part of the machine there are special rollers that support the timber.

The device has a work surface in the form of a table. It consists of 2 parts. One of them supplies the wooden element and the other receives it. Between these surfaces there is a special shaft in the form of a knife, which is used for cutting. After cutting, the wooden element goes to the receiving table. In this part of the machine there are special rollers that support the timber.

When choosing such a device, you should pay attention to the method of supplying lumber to the working area. Some models provide only manual feed, while others can do this automatically.

Jointing machine

A planer is a piece of equipment used to process wood blanks. Different planing machines have different characteristics, but their main purpose is the primary processing of wood before it will be processed on other machines.

A planer is a piece of equipment used to process wood blanks. Different planing machines have different characteristics, but their main purpose is the primary processing of wood before it will be processed on other machines.

These wood processing machines can be of 2 types:

- unilateral;

- bilateral.

The one-sided work is done only on one side of the wooden element, the two-sided one has the ability to simultaneously process two sides (adjacent).

In addition, such machines are divided according to the type of workpiece feeding:

In addition, such machines are divided according to the type of workpiece feeding:

- automatic;

- manual.

The automatic material feeding machine uses a dedicated conveyor mechanism or a built-in ADF.

Copy machine

Copy machines (more often made in the "copy-milling" or "lathe-copy" models) are designed to create a copy of a sample of a wooden product, as close as possible to the original. Such devices allow you to perform work quickly enough, sometimes making several copies of the part at the same time.

Copy machines (more often made in the "copy-milling" or "lathe-copy" models) are designed to create a copy of a sample of a wooden product, as close as possible to the original. Such devices allow you to perform work quickly enough, sometimes making several copies of the part at the same time.  These machines use the template copying technique. This technology allows you to achieve the same shape for all elements of a particular part, as well as accurately copy this part one or more times. Thus, the possibility of a technological error is practically excluded, since most of the stages of sawn timber processing are performed automatically.

These machines use the template copying technique. This technology allows you to achieve the same shape for all elements of a particular part, as well as accurately copy this part one or more times. Thus, the possibility of a technological error is practically excluded, since most of the stages of sawn timber processing are performed automatically.

It should be noted that copying machines have a fairly compact size, but at the same time they are highly durable, even with frequent use, they work for a long time without breakdowns and repairs, if the devices are serviced in time. Moreover, copy-milling machines make it possible to produce elements similar to each other with maximum precision.

Planing machine

Planers are used to shape the wood into the required shape. After processing a wooden product on such a machine, its surface is perfectly flat and smooth, there are no burrs, chips and delamination on it.

Planers are used to shape the wood into the required shape. After processing a wooden product on such a machine, its surface is perfectly flat and smooth, there are no burrs, chips and delamination on it.

The design of this device allows processing a wooden part in any plane:

- vertical;

- horizontal;

- tilted at any angle.

This is due to the fact that all wood planers have a guide bar that adjusts the tilt angle. Due to the fact that the entire structure is sufficiently strong and stable, when working in different planes, it is possible to achieve high precision in processing wood, since the level of vibration is minimal.

The working surface of this machine is divided into two parts:

- mobile;

- motionless.

A moving knife shaft is located between these parts. Its main task is to cut a thin part of a wooden part. As the piece of wood moves across the worktable, the rollers hold the part.

The planer can have two or three knives. If there are three of them, the quality of timber processing is significantly improved. This device has a replaceable set of knives. Some are designed to work with soft lumber, others with harder.

The choice of knives depends on the wood from which a particular bar is made.

Bandsaw machine

The band saws used to cut wood have the main difference that they can be used to cut wood, giving it any shape. This device allows you to make both straight and curved cuts.

The band saws used to cut wood have the main difference that they can be used to cut wood, giving it any shape. This device allows you to make both straight and curved cuts.

By the method of location, such machines are classified into the following varieties:

- vertical;

- horizontal.

Depending on how automated the work in a given design is, such machines are divided into:

- fully automatic (they are used mainly in industry);

- semi-automatic (used for the manufacture of furniture, in such machines the work of the cutting saw and vice is automated);

- manual (in these devices, the material must be fed manually, and the sawing process is also manually adjusted, such machines are considered domestic, used in private workshops).

Also, such devices are classified according to the type of tape:

- with narrow saws (from 2 to 6 cm, most often used for making furniture);

- with wide saw blades (from 10 to 30 cm).

If we consider these machines depending on their power, they appear on:

- carpentry;

- dividing;

- log saws.

In home workshops, there are mainly small-sized and not very bulky, semi-automatic or manual machines.

Combined machines

Combined machines are a device that is often used for woodworking at home. This is very convenient, since it is often not possible to equip a home workshop with many work units.

Combined machines are a device that is often used for woodworking at home. This is very convenient, since it is often not possible to equip a home workshop with many work units.

The combined machine can perform many functions at the same time, for example:

- sawing;

- milling;

- grooving;

- resmus;

- planing.

Industrial combined woodworking machines can be divided into two general categories:

- household;

- professional.

The main differences between these two types are dimensions, motor parameters, supply voltage.

Moreover, some combined type woodworking machines can be made homemade, and can be used just as well at home.

As you can see from the material described in this article, there are special installations for various types of wood processing, each of which copes with its task. Some of them may partially interchange the functionality of each other. Some machines, for example, copying machines, are designed only to perform a specific job. A separate type of woodworking machines for home workshops is combined. Their functionality is broader, and the scope of application extends to many stages of wood processing. It is these devices that are most often chosen for work at home.