Thermal insulation materials targeted by customers

Heat-insulating materials will help the owners to save heat in the room and save on energy resources. This is a smart decision when building or renovating a home. The market most demanded about 5-7 types of building materials in this category. They all have strengths and weaknesses that every contractor should be aware of. For this reason, it is important to go through a master class on how to choose a heater in your own case. A detailed acquaintance with their general characteristics will help to avoid many problems during operation.

Heat-insulating materials will help the owners to save heat in the room and save on energy resources. This is a smart decision when building or renovating a home. The market most demanded about 5-7 types of building materials in this category. They all have strengths and weaknesses that every contractor should be aware of. For this reason, it is important to go through a master class on how to choose a heater in your own case. A detailed acquaintance with their general characteristics will help to avoid many problems during operation.

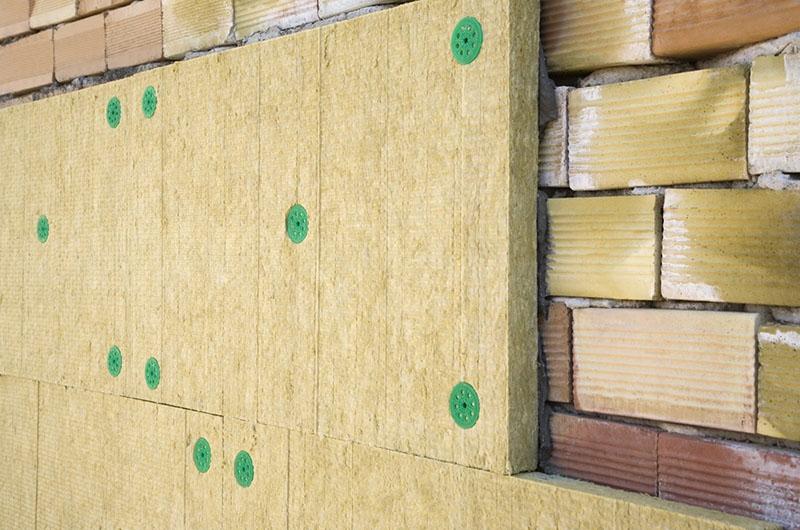

The most popular thermal insulation materials are mineral wool and foam

Other features of the thermal insulation material include:

- neutral reaction to alkaline substances and acids;

- environmental safety of the product;

- fire resistance of the highest category;

- resistance to fungal spores, insects and rodents;

- sound insulation properties;

- temperature regime -180˚С… + 600˚С.

Part mineral wool includes up to 90% of the rock: carbonate and gabbro-basalt. Phenolic resins and bentonite clay are used to bind the fibers. Experts advise to give preference to stone and basalt varieties. In addition, glass wool and slag wool are widely used in construction. They are very similar in their characteristics.

Part mineral wool includes up to 90% of the rock: carbonate and gabbro-basalt. Phenolic resins and bentonite clay are used to bind the fibers. Experts advise to give preference to stone and basalt varieties. In addition, glass wool and slag wool are widely used in construction. They are very similar in their characteristics.

The disadvantage of stone wool is its hydrophobia. Upon contact with moisture, the material deforms and loses all thermal insulation properties. Recommendation: it is necessary to provide the building with high-quality waterproofing.

The second place in the ranking is occupied by polystyrene. The building material is produced by foaming a polystyrene plastic mass. During the production process, gas is formed between the fibers, which increases the density of building boards.

The second place in the ranking is occupied by polystyrene. The building material is produced by foaming a polystyrene plastic mass. During the production process, gas is formed between the fibers, which increases the density of building boards.

Polyfoam is appreciated for a number of advantages:

- light weight;

- moisture repellency;

- thermal stability (from -70˚C to + 100˚C);

- noise isolation (increases protection up to 32 dB);

- fire resistance class 3-4 (self-combustion period 4 sec);

- long service life: 20-50 years;

- thermal conductivity ranges from 0.033 to 0.041 W / (m ∙ K).

All this is possible due to the small diameter of the inner air capsules. The vapor permeability coefficient of expanded polystyrene is quite impressive - 0.03 mg / mchPa. It practically does not allow air to pass through, which is why you have to install an additional ventilation system. At the same time, the water absorption of this building insulation is 1-2% per day.

Among the disadvantages of foam, it is worth highlighting its vulnerability to nitro paints, as well as paints and varnishes. But the low mechanical stability creates problems during installation.

Extruded polystyrene foam

Its "relative" - extruded polystyrene foam is capable of making a worthy competitor to polystyrene. A distinctive feature of this home insulation is the way it is produced. Foaming of polymeric substances is carried out in the extrusion process.The composition is passed through high-strength molds, which leads to the emergence of a unique material with high thermal insulation properties. As a result, water permeability indicators increase by an order of magnitude. In addition, the material becomes capable of withstanding all kinds of loads. Despite its half-century history, extruded polystyrene foam is especially popular with consumers.

Its "relative" - extruded polystyrene foam is capable of making a worthy competitor to polystyrene. A distinctive feature of this home insulation is the way it is produced. Foaming of polymeric substances is carried out in the extrusion process.The composition is passed through high-strength molds, which leads to the emergence of a unique material with high thermal insulation properties. As a result, water permeability indicators increase by an order of magnitude. In addition, the material becomes capable of withstanding all kinds of loads. Despite its half-century history, extruded polystyrene foam is especially popular with consumers.

They appreciate it for:

- thermal conductivity up to 0.032 W / (m ∙ K);

- water absorption no more than 0.2% per day;

- durability (50-80 years);

- environmental friendliness (nevertheless, at + 75˚C, the raw materials begin to emit toxic substances);

- temperature range (-50 ... + 70˚С).

Expanded polystyrene is often used in the construction of industrial facilities.

However, it is often recommended to use it for insulation of the roof, foundation, floor or wells... When exposed to sunlight, EPP loses its unique abilities.

However, it is often recommended to use it for insulation of the roof, foundation, floor or wells... When exposed to sunlight, EPP loses its unique abilities.

The high cost of heat-insulating material does not allow its use everywhere. An impressive coefficient of flammability of raw materials is dangerous for human life. In addition, the composition is destroyed by the action of inorganic solvents. EPP insulates the room so much that it is not uncommon for fungal spores or mold to form in the building. Therefore, a good ventilation system will be a lifesaver in this situation.

Liquid insulation - high technologies of the XXI century in action

Warm paints and foamy substances became a new milestone in the history of the construction era. According to experts, they are the best insulation for walls. The compositions are applied to surfaces with all kinds of reliefs and architectural features. The result of this procedure is a monolithic layer without the formation of "tricky" joints. With the help of this technology, all hard-to-reach places in the house are reliably protected from moisture and cold penetration.

Warm paints and foamy substances became a new milestone in the history of the construction era. According to experts, they are the best insulation for walls. The compositions are applied to surfaces with all kinds of reliefs and architectural features. The result of this procedure is a monolithic layer without the formation of "tricky" joints. With the help of this technology, all hard-to-reach places in the house are reliably protected from moisture and cold penetration.

Other advantages of liquid insulators:

- minimum thermal conductivity 0.001 W / (m ∙ K);

- high refractoriness of the material;

- maintaining a critical temperature of + 220˚С;

- resistance to mechanical stress.

Liquid insulation perfectly protects engineering systems (ventilation, water supply and air conditioning) from atmospheric influences. Condensation does not form on the pipes, which serves as a precursor to corrosion.

Thanks to the above-mentioned characteristics of the gastrointestinal tract, they can reduce the cost of heating resources by up to 30%.

Thanks to the above-mentioned characteristics of the gastrointestinal tract, they can reduce the cost of heating resources by up to 30%.

Such indicators can be achieved with the help of the demanded varieties of these thermal insulation materials:

- polyurethane foam;

- penoizol;

- actor;

- corundum (ultra-thin insulation);

- warm paint;

- astratek;

- polynor;

- armor.

The gastrointestinal tract is distinguished by a high coefficient of adhesion to the treated surface. Liquid ceramics prevents the formation of corrosion processes and rust on metal structures. Yet a significant drawback of this composition is the sensitivity of the substance to transportation. In addition, it is very difficult for contractors to calculate the amount of slurry consumed. This, in turn, increases the consumption of liquid insulation. And its value on the market is measured in thousands of rubles.

The gastrointestinal tract is distinguished by a high coefficient of adhesion to the treated surface. Liquid ceramics prevents the formation of corrosion processes and rust on metal structures. Yet a significant drawback of this composition is the sensitivity of the substance to transportation. In addition, it is very difficult for contractors to calculate the amount of slurry consumed. This, in turn, increases the consumption of liquid insulation. And its value on the market is measured in thousands of rubles.

Only a millimeter layer of the gastrointestinal tract in its characteristics is not inferior to a layer of mineral wool of 50-70 mm.

Foil insulation - versatile in the field of thermal insulation

The versatile material serves as an excellent heat insulator as well as its unique reflector. Manufacturers apply polyethylene foam on one side of the board, and polished foil on the other. As a result, the percentage of reflection reaches 60-97%.

The versatile material serves as an excellent heat insulator as well as its unique reflector. Manufacturers apply polyethylene foam on one side of the board, and polished foil on the other. As a result, the percentage of reflection reaches 60-97%.

In addition, foil insulation:

- have excellent water-repellent properties;

- are distinguished by a cellular structure, due to which proper air circulation is ensured;

- absorb up to 20 dB of sound waves.

Heaters of this series are made from different materials. Polyethylene or mineral wool is usually taken as a basis.

The service life of the building material is indicated on the packaging - 95 years, depending on climatic conditions. Despite such a long period, the foil-clad product does not lose its quality characteristics. In addition, the insulator withstands abnormal temperature fluctuations, gusts of wind, ultraviolet radiation, as well as radon radiation.

The service life of the building material is indicated on the packaging - 95 years, depending on climatic conditions. Despite such a long period, the foil-clad product does not lose its quality characteristics. In addition, the insulator withstands abnormal temperature fluctuations, gusts of wind, ultraviolet radiation, as well as radon radiation.

Fiberboard comes from the forest

The composition of the thermal insulation material includes thin softwood. Manufacturers choose caustic magnesite as a binder for it, which makes fiberboard the most environmentally friendly insulator in the world. Its alternative is often cement or liquid glass.

The composition of the thermal insulation material includes thin softwood. Manufacturers choose caustic magnesite as a binder for it, which makes fiberboard the most environmentally friendly insulator in the world. Its alternative is often cement or liquid glass.

For fixed formwork, fiberboard plates are used for 4 reasons:

- fire resistance of the highest class (T1);

- Breathable structure;

- resistance to pests, decay and mold;

- no deformation under load.

Gas voids are concentrated between the fibers of the fibrolite. They prevent sound waves from entering the building and heat flows from leaving it.

Although the material is moisture-resistant insulation, it is not recommended to install it in rooms with a humidity of more than 75-80%. If it is necessary to protect the slabs from dampness, then a layer of plaster is applied to them or additional waterproofing is installed. The service life of this product is 50-70 years. In addition, it can withstand up to 50 cycles, which indicates its high frost resistance.

Although the material is moisture-resistant insulation, it is not recommended to install it in rooms with a humidity of more than 75-80%. If it is necessary to protect the slabs from dampness, then a layer of plaster is applied to them or additional waterproofing is installed. The service life of this product is 50-70 years. In addition, it can withstand up to 50 cycles, which indicates its high frost resistance.

Considering the above features of thermal insulation materials, the master will be able to choose the best option for his home and bank account. At the same time, he should remember that an investment in renovation is a reliable investment for more than one decade.

A very interesting article about thermal insulation materials! Well, of course, now the most popular are mineral wool and foam!