Laying the laminate with your own hands will be successful if you follow the instructions

Do-it-yourself laminate flooring is quite simple. But if you do not know some of the nuances, then you can severely spoil the entire structure, so that it will become unusable. In addition, you need to know how to position the boards so that the floor not only serves for a long time, but also looks beautiful. That is why this article discusses instructions for laying laminate flooring.

Do-it-yourself laminate flooring is quite simple. But if you do not know some of the nuances, then you can severely spoil the entire structure, so that it will become unusable. In addition, you need to know how to position the boards so that the floor not only serves for a long time, but also looks beautiful. That is why this article discusses instructions for laying laminate flooring.

Laminated panel structure

Laminate flooring consists of several layers:

- Upper. It protects the decorative paper from damage. The wear resistance of the laminate is influenced by the thickness and strength of the top layer. It also makes the board shiny. In addition, the top layer is embossed so that it looks more like parquet.

- Decorative. Paper that has a pattern of a board or other surface.

- Base. It can be made of plastic or fiberboard. In it, locks are cut along the edges, with the help of which the panels are fastened together. Resistance to moisture largely depends on the base, its impregnation, density.

- Lower. Its task is to prevent deformation of the board. It makes the panel much more rigid. In some models, there is another layer under the bottom layer - an insulating one. The structure allows for increased thermal insulation and sound insulation.

The modern laminated board has a four-sided winding lock. There are long parts of the constipation on both sides - these are the elements that are visible from above in the form of a protrusion extending from below. The short parts of the lock are at opposite ends of the board and are not visible from above. In the picture above, the long section is on the left and the short section on the right.

Installation plan and design issues

Laminate flooring must not be laid in a single contour over the entire area of the apartment. It must be installed separately in each room. Otherwise, the coating may bulge. Even if the laminate is expensive, of high quality and has a guarantee against expansion due to moisture, it is still better to be insured.

Laminate flooring must not be laid in a single contour over the entire area of the apartment. It must be installed separately in each room. Otherwise, the coating may bulge. Even if the laminate is expensive, of high quality and has a guarantee against expansion due to moisture, it is still better to be insured.

Do not use laminate flooring in bathrooms, toilets, lavatories. It absorbs moisture quite well and deteriorates from this.

The tiles can be laid diagonally or along walls. The first option is undesirable. Firstly, this type of DIY laminate laying will completely ruin any apartment design, since furniture and walls will conflict with such a contour. Secondly, this is a difficult method, because it will be necessary to saw off the laminated boards at an angle, which often leads to chips.

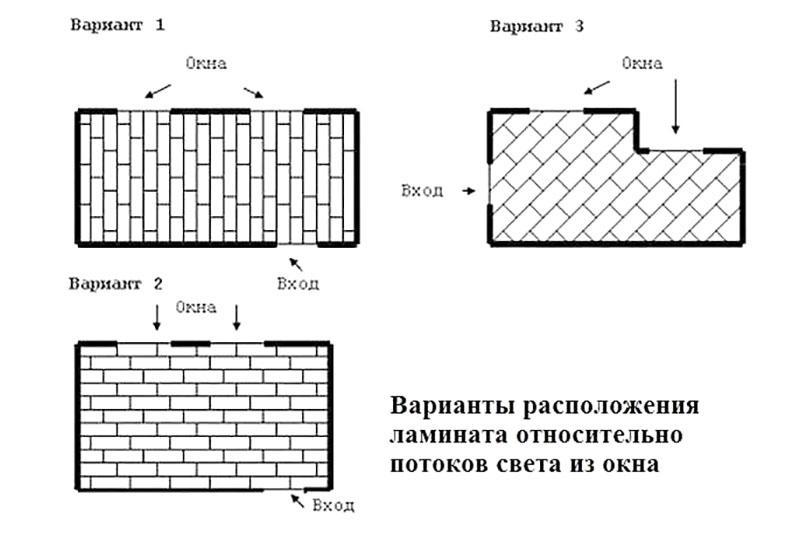

There is only one option left - along the wall. But which one? For the correct choice, you must also remember that there are two more types of orientation - in the light and in the direction of travel:

- Parallel to the rays of light. In this case, the longitudinal joints are fully illuminated, which makes them less visible. Therefore, laying the laminate with your own hands in a room with a window is done by light. Then the highlights on the floor will be solid and more natural. Moreover, if boards are laid in a single contour, then you need to focus on living rooms (most of them), since their area in any case exceeds the size of the corridors and the kitchen.

- Parallel to the movement. This layout allows you to scuff your feet along the joints rather than across, which reduces panel wear.However, in most cases this is not relevant, since modern laminate flooring is quite durable (unless we are talking about cheap options). The exception is corridors in large offices, where there are a lot of people and very busy traffic. In this case, the laminate is laid in the direction of travel.

DIY laminate laying methods

There are three ways to choose the size of the indentation:

- Each next row is shifted relative to the previous one by the width of one element. For example, there is a 20 cm wide laminate. The first row was laid close to the wall, the second was moved 20 cm, the third - 40 cm, and so on. You can't do that. Firstly, any manufacturer requires that the transverse seams are spaced at least 30 cm apart so that the load is distributed evenly. Secondly, it is bad from a visual point of view, as there are clear diagonal lines formed by the seams.

- Laying with a brick, when each next row is shifted by half the length of the element. This is the classic choice of many installers. It is easy to do, and the harness is strong. But this layout has one drawback - the transverse seams are very close to each other, literally across the same board. In this case, a pronounced dotted line is created. Taking into account the fact that the board in living quarters is usually placed in the light, these longitudinal seams will be highlighted with shadows as much as possible and will create unnecessary visual noise.

- Each next row is shifted relative to the previous one by one third of the length of one element. The transverse seams will be more spaced apart and will not form transverse dotted lines. At the same time, the overall layout looks more interesting. In addition, this type of contour will remain strong and durable enough.

Also remember that the pattern on the boards can be repeated. Such identical slabs should be placed far from each other so that their similarity is not striking.

Do-it-yourself straight-line laminate laying with step-by-step instructions on the video:

Diagonal laying of the laminate with your own hands in the video:

Preparing for laying laminate with your own hands

Required tools and materials:

- the laminated panels themselves;

- substrate (insulation) for them;

- simple pencil (soft);

- spacer wedges 10-12 mm thick (for large rooms - up to 15 mm);

- undercut bar;

- electric jigsaw;

- regular saw;

- circular saw;

- hammer;

- roulette;

- bracket.

You can lay the panels in a room where the temperature is in the range of 15-30oC, and the humidity is around 40-70%. In this case, the panels must lie in the room for 48 hours so that they adapt to the local humidity and do not swell.

The floor must be perfectly flat, otherwise the locks will break from the load, and the whole structure will crack.

First of all, they put insulation. If installed on a wooden floor, soundproofing is sufficient. But if it is concrete, then first a water-insulating layer is put, and then sound insulation is applied to it. If there is a floor heating system, then in any case, first you will need insulation from moisture, and then - sound.

Even if no insulation is needed, a backing is still needed to cushion the locks. So it must be laid in any case. However, it is impossible to use a polyethylene foam backing, as it quickly loses its properties. It is advisable to purchase sheets based on extruded polystyrene foam or use a cork covering.

Even if no insulation is needed, a backing is still needed to cushion the locks. So it must be laid in any case. However, it is impossible to use a polyethylene foam backing, as it quickly loses its properties. It is advisable to purchase sheets based on extruded polystyrene foam or use a cork covering.

You can lay laminate on linoleum. But only if there is no fungus or pebbles under it, the floor is perfectly flat, and the canvas itself did not go in waves, did not crack or stiffen. In addition, it is desirable that linoleum be laid on mastic or glue (but not freely). In general, it is better to refuse such an idea.

For correct installation of the substrate, we measure the length and width of the room, we determine how many whole strips will enter the room.If the final row is less than half a laminate board, then it is advisable to make the first one already. Otherwise, the plates will subsequently become difficult to start, and they will not hold well. If the wall is uneven, then the cut strip of the substrate is pushed close to the wall and the excess is cut out.

For correct installation of the substrate, we measure the length and width of the room, we determine how many whole strips will enter the room.If the final row is less than half a laminate board, then it is advisable to make the first one already. Otherwise, the plates will subsequently become difficult to start, and they will not hold well. If the wall is uneven, then the cut strip of the substrate is pushed close to the wall and the excess is cut out.

Installation instructions

Look at the step-by-step instructions for laying the laminate with your own hands:

- First you need to calculate how many boards are required in one row, as well as how many rows themselves are required.

- For ease of assembly, the first row is laid with the short side of the lock against the wall.

- Before installing the laminate, wedges with a thickness of 10-12 mm are placed around the entire perimeter. With their help, a gap should be created between the boards and walls. The gap is needed so that the floor can absorb moisture and expand without giving rise to waves and swelling. Boards must not be nailed or screwed on or glued.

- For convenience, a row is first assembled, that is, the boards are connected in end locks. To do this, one must be brought into the other at an angle of 45 degrees, and then lowered, while simultaneously pressing forward. In this case, it is necessary to ensure that the boards are connected parallel to each other.

- Approaching the opposite wall, you need to measure the required length at the last board. To do this, it is turned over to the top with its “belly” and placed against the wall, making a technological indent of a centimeter. Then a mark is drawn and a line is drawn using a square.

- The excess piece is sawn off with a circular saw. The cut off part can be used to start a new row (if fit).

- Once the first row has been assembled, it can be cut to the width so that when the entire laminate is laid, the latter is not too thin. Of course, this requires measurements.

- To create the second row, you need to step back at least 30 cm from the wall. That is, the first board is deliberately shortened so that the slabs lay like a brick. So the joints between them become stronger, and the load is distributed more evenly.

- Subsequent rows are done according to the same principle. That is, first a row is assembled, and then it is mounted in the previous one. To do this, he is raised and placed at an angle of 45about, and then push it in. You cannot hammer them into each other with a hammer. The boards are specially made so that you can handle it with your hands.

- The hammer is needed to tighter the rows. After laying each 4-5 rows, a dam is used. It is placed on the last row from the top, and a hammer is gently hit on it parallel to the floor.

- The last row with the short side of the lock enters the long one, but before that the boards are cut off. For laying, a metal bracket must be used so that the plates fit tightly into the grooves.

- At the end, the spacer wedges are removed, and the technological gap is hidden by the baseboard.

Operating rules

Do not use chemical detergents for cleaning. You can only use a dry soft brush and vacuum cleaner. In general, moisture should not be allowed; a slightly damp cloth can be used for washing. In addition, the legs of all furniture should have soft pads so that they do not scratch the floor.