How to make a time-tested Dadant hive with your own hands

More than 100 years ago, a French beekeeper designed a unique structure that is still used today to extract large quantities of honey. Today, even a beginner can create a Dadan hive with his own hands if he follows the advice of professionals. They consist of a detailed description of the design, the dimensions of the hives and well-written drawings. In addition, a list of suitable tools and required material is provided. And the order in which the work is done will prompt you to get to work.

More than 100 years ago, a French beekeeper designed a unique structure that is still used today to extract large quantities of honey. Today, even a beginner can create a Dadan hive with his own hands if he follows the advice of professionals. They consist of a detailed description of the design, the dimensions of the hives and well-written drawings. In addition, a list of suitable tools and required material is provided. And the order in which the work is done will prompt you to get to work.

Characteristics of a unique bee house

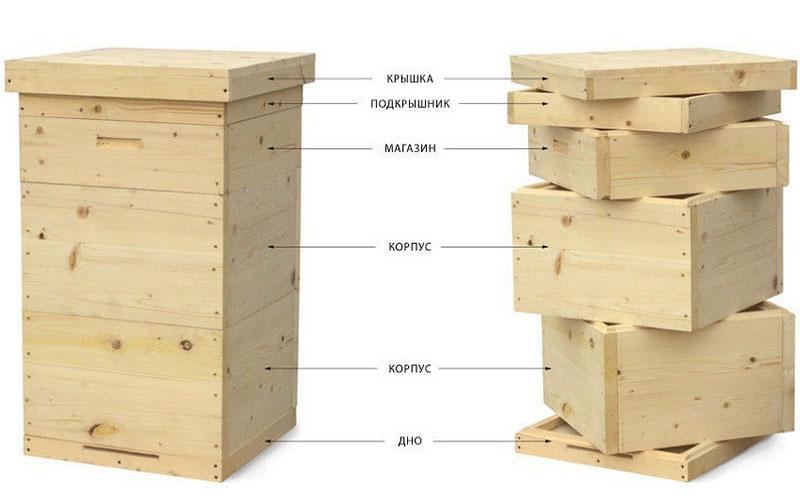

The result is the time-tested Dadant hive, which consists of the following parts:

- body;

- cap;

- removable bottom;

- framework.

Often, experts supplement the design with "shops" in the form of compact boxes. The body has a square or rectangular shape. The back wall is double, the rest are single. There is a notch in the middle of the lower front wall. It is a hole with a length of 220 mm and a height of 8 mm.

The standard design of the Dadanov hive can accommodate up to 12 frames. Their ideal size allows insects to thrive and harvest honey. A canvas and a special pillow are used to cover the frames. The distance between them is set using a zigzag wire. It is located on the side walls of the hive.

The standard design of the Dadanov hive can accommodate up to 12 frames. Their ideal size allows insects to thrive and harvest honey. A canvas and a special pillow are used to cover the frames. The distance between them is set using a zigzag wire. It is located on the side walls of the hive.

Sometimes beekeepers use 16 frames in a hive. However, such a number of structures have to be serviced only with a partner.

A removable hood covers the top of the bee house. It must completely encircle the structure. There is a ventilation hole in the front. Inside it is closed with a net. The lower part of the structure is equipped with a removable bottom. It is disconnected during the "spring cleaning" of the bee house.

For those who are ready to "build" the Dadan hive with their own hands, we note several of its advantages:

- vertical breeding of bees;

- an abundance of free space for insects;

- comfortable downloading of a sweet product;

- a better product is obtained from the store compartments;

- protective treatment of bees is carried out only in the nesting part of the hive.

The existing drawbacks do not prevent the active use of the structure in bee breeding. For example, the assembled Dadant hives are very bulky, so they are inconvenient to transport. Since insects hibernate in nesting compartments, and honey is laid in half frames, they need to be fed in autumn and winter. Otherwise, bee houses are ideal abode for valuable insects.

Do-it-yourself Dadan hive

Before starting work, experienced craftsmen advise to collect the necessary tools:

- hammer;

- planers of two types (falsebel and tongue-and-groove);

- Workbench;

- fine-toothed saw;

- ticks;

- bit;

- nails;

- self-tapping screws of different lengths;

- drill.

In addition, to make the Dadan hive, you will need high-quality pine, willow, linden or birch... Approximately 2 m² of planed boards 2.5 cm thick and 12 cm wide are used for the body and the bottom. 1.25 m² of timber is sufficient for the rest of the structural elements. All material is treated with a special oil paint to protect it from decay.The boards are cut in accordance with the generally accepted dimensions of the Dadanov hive.

In addition, to make the Dadan hive, you will need high-quality pine, willow, linden or birch... Approximately 2 m² of planed boards 2.5 cm thick and 12 cm wide are used for the body and the bottom. 1.25 m² of timber is sufficient for the rest of the structural elements. All material is treated with a special oil paint to protect it from decay.The boards are cut in accordance with the generally accepted dimensions of the Dadanov hive.

For a 12-frame structure, prepare:

- 6 side and 3 outer walls 498 mm long;

- 6 pieces of outer front and inner rear walls (450 mm);

- 5 bottom elements (465 mm);

- 2 blocks under the base (800 mm).

The source material must be flawless. If pine, spruce or cedar wood is used for the case, it must be dried within 1 year. During this time, it is completely freed from resin. If desired, the Dadan hive can be built from fiberboard or plywood. This material contains layers of both deciduous and coniferous trees. Some bee lovers make their hives out of durable plastic. However, such designs are short-lived.

An important factor is the preparation of the insulating material. For the southern regions, where there are no harsh winters, hives are created with single side walls. This results in a lightweight construction with good ventilation. For beekeepers who live in mid-latitudes, it is better to make a Dadan hive with double walls. And the space between them is filled with insulating material made of sawdust, straw or foam.

An important factor is the preparation of the insulating material. For the southern regions, where there are no harsh winters, hives are created with single side walls. This results in a lightweight construction with good ventilation. For beekeepers who live in mid-latitudes, it is better to make a Dadan hive with double walls. And the space between them is filled with insulating material made of sawdust, straw or foam.

You will also need 130 cm of wire for the elbow lock, metal mesh with a minimum mesh size of 4 mm, plywood, casein glue or PVA.

It is better to choose a wire with a large cross section in order to obtain a strong structure.

Preparatory activities

Before you make a Dadanov hive with your own hands, you must carefully study the diagrams and drawings. They are created by experienced craftsmen for every detail of the design. At the same time, the standard sizes of the hives are indicated on paper. To create a "house" for 10 frames, use the classic parameters. The body height is allowed from 310 to 320 mm. Magazine from 155 to 165 mm. Roof - 70-80 mm. The bottom is usually 70 mm. The length and width of the listed elements are in the range of 450-520 mm. The rebate depth is 18 mm, taking into account the space left between the top cut and the frame. The gap from the bottom to the frames is 25 mm, which will be used when cleaning the bee house.

Before you make a Dadanov hive with your own hands, you must carefully study the diagrams and drawings. They are created by experienced craftsmen for every detail of the design. At the same time, the standard sizes of the hives are indicated on paper. To create a "house" for 10 frames, use the classic parameters. The body height is allowed from 310 to 320 mm. Magazine from 155 to 165 mm. Roof - 70-80 mm. The bottom is usually 70 mm. The length and width of the listed elements are in the range of 450-520 mm. The rebate depth is 18 mm, taking into account the space left between the top cut and the frame. The gap from the bottom to the frames is 25 mm, which will be used when cleaning the bee house.

Usually, classic drawings of Dadant hives for 10 frames include all parameters and structural elements:

- the housing where the nest is located;

- shop for collecting honey;

- a stand that protects the hive from pests, cold and dampness;

- roof.

The dimensions of the "dwelling" for bees on 12 frames correspond to generally accepted data:

- case height 320 mm;

- length of connecting strips 450 mm;

- roof liner 100 mm.

The rest of the parameters are presented in the drawings of Dadant's hives for 12 frames, shown in the photo. Only after a thorough analysis of the schemes do they get down to business. For the manufacture of the structure, boards with a thickness of 4 cm are suitable.

The rest of the parameters are presented in the drawings of Dadant's hives for 12 frames, shown in the photo. Only after a thorough analysis of the schemes do they get down to business. For the manufacture of the structure, boards with a thickness of 4 cm are suitable.

To give more space for the movement of the bees, the height of the frames is increased. As a result, the structure can reach 90 cm.

Phased order of work

First of all, markings are made on boards with a thickness of 3.5-4 cm. To do this, use the parameters indicated on the paper and cut out the connecting grooves. On the inside of the walls, metal corners are attached at all corners.

First of all, markings are made on boards with a thickness of 3.5-4 cm. To do this, use the parameters indicated on the paper and cut out the connecting grooves. On the inside of the walls, metal corners are attached at all corners.

Body assembly

To create folds, 12 mm wide strips are placed at the top. Next, a notch with a depth of 0.8 cm is cut out. It is placed on the front wall in its lower region. After that, they start assembling the case.

To create folds, 12 mm wide strips are placed at the top. Next, a notch with a depth of 0.8 cm is cut out. It is placed on the front wall in its lower region. After that, they start assembling the case.

The front, back and side walls are made of planks. They are connected using self-tapping screws or nails, screwing or driving into the edge at a slight slope. From the inside, a thorn is cut off and niches with a depth of 14 mm and a width of 12 mm are cut out. They will become the support for the frames. Bars are nailed to the top of the hive to support the roof of the hive.

Cranked wire

To position all frames at the same distance, you need a special wire. To do this, 13 screws are fixed into the wooden base, focusing on one line. The distance from the extreme point of the bar is not more than 2.5 cm. A gap of 40 mm is observed between the extreme screws.The rest of the parts are placed at a distance of 37 mm. A wire is wrapped around the installed screws, which is fixed to the side walls. The result is a cranked configuration.

To position all frames at the same distance, you need a special wire. To do this, 13 screws are fixed into the wooden base, focusing on one line. The distance from the extreme point of the bar is not more than 2.5 cm. A gap of 40 mm is observed between the extreme screws.The rest of the parts are placed at a distance of 37 mm. A wire is wrapped around the installed screws, which is fixed to the side walls. The result is a cranked configuration.

Floor and roof installation

The removable floor of the Dadan hive is made by joining 5 planks 1.5 inches thick. Then they are knocked down with two bars, the distance between which is 35 cm.To install the part on the body, a triangular corner is cut off from the bar, and the stern is sawed on the board. Thanks to this, the removable floor fits perfectly into the main body.

The removable floor of the Dadan hive is made by joining 5 planks 1.5 inches thick. Then they are knocked down with two bars, the distance between which is 35 cm.To install the part on the body, a triangular corner is cut off from the bar, and the stern is sawed on the board. Thanks to this, the removable floor fits perfectly into the main body.

It is advisable to install screws or nails obliquely in order to get a reliable bottom of the hive.

When creating a roof, pay attention to the following nuances:

- the length of the side walls must be within 563 mm;

- width from the front side about 280 mm;

- back wall - 100 mm.

The edges of the protruding boards are cut at right angles. A ventilation slot is made on the upper part. Its size is 2x9 cm. A mesh is nailed inside, the cells of which must be at least 4 mm. The prepared parts are fastened with nails, and then installed over the body. The roof is covered with a suitable material from above. It can be iron or roofing material.

The roofing material should protrude from the body by about 8 cm at the front and rear, and 6 cm from the sides.

The procedure for arranging a bee house

Dadant's do-it-yourself hive is covered with canvas. The material is pre-treated with oil paint from the back and the outside. Oilcloth or planks are often used as a tire, the size of which is 510x160x12 mm.

Dadant's do-it-yourself hive is covered with canvas. The material is pre-treated with oil paint from the back and the outside. Oilcloth or planks are often used as a tire, the size of which is 510x160x12 mm.

The hive is insulated from a canvas-covered frame. The resulting space is filled with wood chips, batting or sphagnum moss. In the central part, a hole is cut out for feeding insects. Its parameters are 110x110 mm.

We examined in detail how to make a Dadanov hive with our own hands. Drawings are usually provided by experienced craftsmen. Work begins with the preparation of tools and material. Then they study the schemes and determine the size of the structure. Following the advice of specialists, they assemble the body, floor, roof and additional parts. As a result, on apiary a new DIY bee house will appear. Such work brings true satisfaction and joy.