How to make and install do-it-yourself swing garage doors

Garage doors swing doors will be the best choice for the garage owner who values high reliability at a low price. It is this design that will allow the car enthusiast to be calm about the iron horse left in the garage and save as much as possible at the same time. And what is also important - such gates are the easiest to mount and install yourself.

Garage doors swing doors will be the best choice for the garage owner who values high reliability at a low price. It is this design that will allow the car enthusiast to be calm about the iron horse left in the garage and save as much as possible at the same time. And what is also important - such gates are the easiest to mount and install yourself.

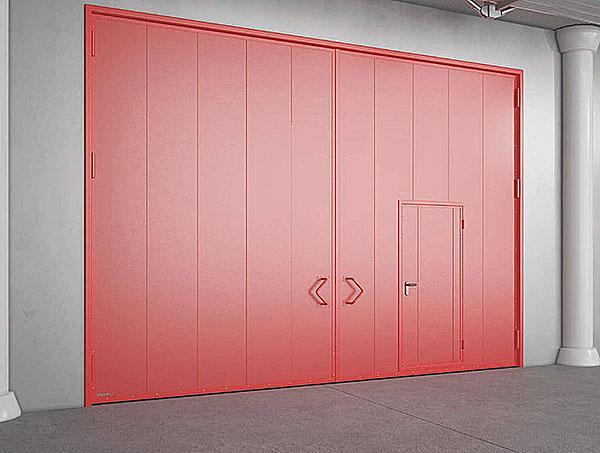

What do swing gates look like?

- frames to fit the doorway;

- two leaves;

- loops;

- fittings - locks, handles, alarm systems and various limiters that hold the gate in the desired position.

Very often in one of the valves they have gate... Also, for ease of use, the gates are equipped with remote-controlled automatics that allow you to open the doors without leaving the car. Most often, swing garage doors are made of metal - the frame of the frame is welded from the profile, hinges and door leaf are welded onto it from steel sheet 3-5 mm thick. If safety is not so important for the car owner, steel sheets are replaced with profiled sheets, panels or wood.

Over time, the doors on swing gates can begin to sag. This is most often due to weak loops. Therefore, before purchasing accessories for garage doors, it is necessary to calculate the mass of the assembled sash and select hinges with a margin of safety.

How to make a swing gate with your own hands

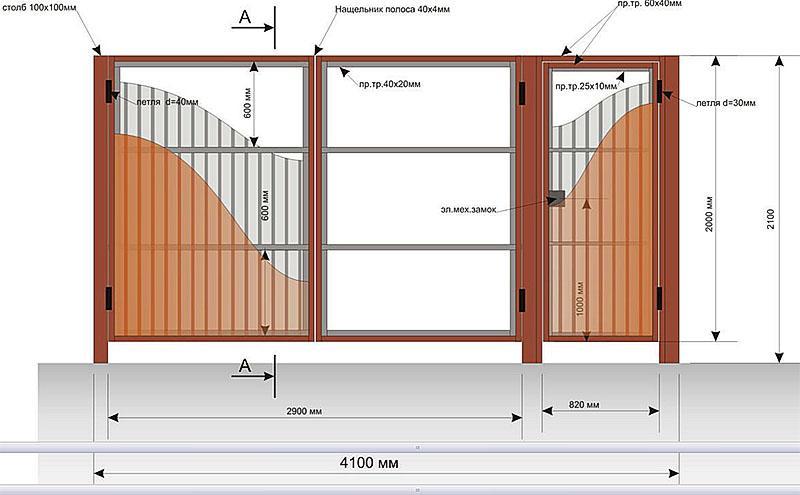

To make a garage door with your own hands, you will need drawings containing all the necessary information about the location, dimensions of the doors, the attachment points for hinges and locks. Experience with a welding machine and locksmith skills will come in handy.

To make a garage door with your own hands, you will need drawings containing all the necessary information about the location, dimensions of the doors, the attachment points for hinges and locks. Experience with a welding machine and locksmith skills will come in handy.

Make sure there is enough space in front of the garage for a car with the doors fully open. When everything is accounted for on paper, prepare the following materials:

- a profile pipe with a section of 60x40 mm for the frame of the doorway;

- corner for making the frame of the doors;

- steel sheets up to 5 mm thick;

- loops;

- all the necessary accessories.

You will also need tools:

- building level;

- welding machine;

- Bulgarian;

- roulette.

If the gate will be equipped with automatic equipment, select a set of equipment in advance and think over the electrical wiring to the installation site.

Separately take care of purchasing protective equipment - a mask and a welder's suit, goggles and a respirator, gloves.

When working with a grinder and a welding machine, there is a great risk of damaging your eyes, therefore, in no case, do not neglect all necessary protective equipment.

We make a metal frame of the doorway

Since we already have all the necessary drawings, the dimensions for all elements of the garage door must be taken from them and carefully measured with a tape measure before cutting. Having cut off four frame parts with a grinder, they are laid out on a flat surface, avoiding distortions. The frame is welded at the corners, constantly controlling the horizontal level of the entire structure and its shape. It should be strictly rectangular. The finished frame is attached to the walls of the garage with anchor bolts.

Since we already have all the necessary drawings, the dimensions for all elements of the garage door must be taken from them and carefully measured with a tape measure before cutting. Having cut off four frame parts with a grinder, they are laid out on a flat surface, avoiding distortions. The frame is welded at the corners, constantly controlling the horizontal level of the entire structure and its shape. It should be strictly rectangular. The finished frame is attached to the walls of the garage with anchor bolts.

We weld the frame of the sashes

Frames for both leaves are made in the same way as the frame of the opening itself, observing the size and shape of the frame.In the course of work, the compliance of the dimensions of both frames should be checked - the inner one should fit into the outer one exactly, without forming gaps and inconsistencies. For the doors to move freely, the optimal clearance between the frames should be 5–7 mm. When welding and fitting, wooden inserts of the appropriate thickness are inserted between the frames.

Frames for both leaves are made in the same way as the frame of the opening itself, observing the size and shape of the frame.In the course of work, the compliance of the dimensions of both frames should be checked - the inner one should fit into the outer one exactly, without forming gaps and inconsistencies. For the doors to move freely, the optimal clearance between the frames should be 5–7 mm. When welding and fitting, wooden inserts of the appropriate thickness are inserted between the frames.

To give the entire structure the necessary rigidity, the frame is reinforced with diagonal elements. As a rule, the diagonal parts come from the attachment points of the upper hinges and come together at the bottom center of the goal.

The door leaf is welded onto the finished frame - steel sheets. Note that the gaps between the sash frames and the frame must be covered with steel sheets.

The door leaf is welded onto the finished frame - steel sheets. Note that the gaps between the sash frames and the frame must be covered with steel sheets.

If desired, a wicket is arranged in one of the doors.

At the end of welding work on the frame, all seams should be sanded and painted over. In this case, burrs on the seams will not interfere with the free movement of the doors, and the welded joints will not rust.

Welding on hinges and hanging the gate leaves

Standard hinges for hinged gates consist of an upper and a lower part. The lower part, on which the pin is located, is welded onto the gate frame, and the upper part - onto the sash. Since swing garage doors are heavy, you need to hang them with assistants. High accuracy is also required at this stage of work. The smooth running of the shutters and the serviceability of the entire structure depend on correctly installed hinges.

Standard hinges for hinged gates consist of an upper and a lower part. The lower part, on which the pin is located, is welded onto the gate frame, and the upper part - onto the sash. Since swing garage doors are heavy, you need to hang them with assistants. High accuracy is also required at this stage of work. The smooth running of the shutters and the serviceability of the entire structure depend on correctly installed hinges.

If the sash assembly is very heavy, it is better to hang them in a horizontal position. In this case, the frame of the opening after manufacturing is attached to the walls of the garage last.

Automatic swing gates

The use of automation for swing garage doors has long been a surprise. There is a large selection of automatic systems and drives on sale that can make entering and leaving the garage as comfortable as possible. In addition to comfort, the automatic gate drive provides:

The use of automation for swing garage doors has long been a surprise. There is a large selection of automatic systems and drives on sale that can make entering and leaving the garage as comfortable as possible. In addition to comfort, the automatic gate drive provides:

- increased service life of the loops;

- stable load on the supporting frame;

- smooth operation in all weather conditions.

The higher the gate and the greater the weight of the wings, the greater the need to equip the gate with automatic equipment, especially if women regularly use the gate.

Automatic gates are convenient because there is no need to manually lock them. Automation blocks any attempts to open doors with hands until a signal is received by the control sensor. The downside in this system is the dependence of work on the presence of electric current. Without light, mechanics simply won't work. To solve the problem, an unlocking system is installed. Most often it comes as an additional option to the drive kit. An alternative is to connect the automation to a backup power source - a battery or a generator.

Currently, there are two types of drives for automatic swing gates - lever and linear. The latter is preferable, since it is designed for a large leaf weight and strong gusts of wind.

Painting and insulation of gates

Before painting, clean the metal surface with a grinder. Then the gate is covered with a primer in two or three layers and paint for metal, suitable for external work.

Before painting, clean the metal surface with a grinder. Then the gate is covered with a primer in two or three layers and paint for metal, suitable for external work.

For most car enthusiasts, the presence of insulation in the garage is a necessity so that all car maintenance work is carried out under normal temperature conditions. In addition, a workshop is often arranged in the garage. As a heater for swing garage doors, polystyrene, mineral wool, felt, cork slabs, penoizol, extruded polystyrene are usually used.

After installing fittings, insulation and painting, swing garage doors can be considered completely finished.