DIY indirect heating boiler - simple and economical

The problem of hot water becomes relevant where there is no centralized hot water supply: in country houses, private city and country houses. Today, the installation of a ready-made device for heating water to the required temperatures requires a serious investment. An alternative way of dispensing hot water is indirect heating boiler

, which you can make yourself. Its advantage is that hot water supply of residential premises is carried out in an economical mode and at minimal financial costs.

The problem of hot water becomes relevant where there is no centralized hot water supply: in country houses, private city and country houses. Today, the installation of a ready-made device for heating water to the required temperatures requires a serious investment. An alternative way of dispensing hot water is indirect heating boiler

, which you can make yourself. Its advantage is that hot water supply of residential premises is carried out in an economical mode and at minimal financial costs.

Features and diagram of making an indirect heating boiler with your own hands

In appearance, an indirect heating boiler is a large storage tank, independent of energy sources (gas, electricity, etc.). Inside the tank, made of corrosion-resistant material, there is a spiral-shaped tube through which the coolant circulates. Cold water is supplied to the tank through an inlet pipe, usually located at the bottom. Heating water in the boiler occurs evenly due to the moving heat carrier of the heating system. The hot water outlet pipe is installed at the top. For ease of use, the pipes are equipped with ball valves. The outside of the tank is covered with a layer of thermal insulation.

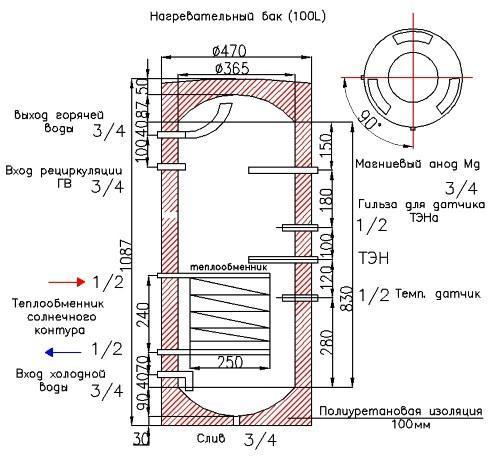

A drawing of the manufacture of an indirect heating boiler with a volume of 100 liters is shown below:

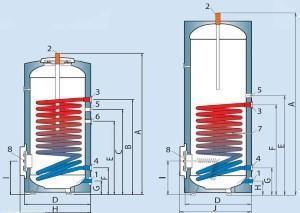

Schematic diagram of the boiler operation:

Heating water from the boiler enters the tank of the water heater, where, passing through a spiral tube, it is converted into cold water at the outlet. Return chilled water flows back to the boiler.

Advantages and disadvantages of an indirect heating boiler

Pros of using a DIY boiler:

- connection to the central heating system;

- installation near a heating boiler;

- insignificant costs for installation of the circuit;

- significant reduction in energy consumption;

- providing water at a constant temperature.

The disadvantages include the following:

- a large area or a separate room is required to install a boiler;

- it takes a long time to heat a large volume of water, while heating the premises will be carried out at a lower intensity;

- rapid formation of deposits on the serpentine tube, requiring chemical or mechanical cleaning twice a year.

This option for obtaining hot water is suitable during the heating season. At other times, the role of the coolant can be played by an electric heating element built into the boiler tank.

Then the water will be heated using electricity. In this case, you can turn on the boiler at night, when night, low rates are in effect, or as needed.

Making a boiler with your own hands

Due to the rather simple principle of operation, such a device can be made independently. Now let's look at how to make an indirect heating boiler with your own hands.

All work on the manufacture of a water heater consists of assembling the components of the structure:

Tank

A tank is used as a boiler tank. Its volume depends on the needs of the owners of the house for hot water and is calculated from the amount of 50–70 liters per person daily. Roughly for a family of 4, a 200-liter boiler is suitable.

For the heating device, the tank must be made of stainless steel, aluminum alloys or other material resistant to corrosion. As an alternative - a gas cylinder, but its walls must first be cleaned and primed. Without this action, hot water will smell like gas.

5 holes are made in the tank: 2 on the side for mounting the coil, one at the bottom for the inlet pipe, one at the top for taking water and one at the bottom for the drain valve. To use the boiler outside the heating season, the installation of a heating element should be provided. A lower hole is also drilled for it. Shut-off elements or ball valves are attached to the holes drilled.

Coil

For this element, a copper or brass tube is suitable, the diameter and length of which depend on the volume of the tank. On average, 1.5 kW of heat output of the serpentine tube is calculated for every 10 liters. You can use a tube made of metal-plastic or other metal with good heat dissipation.

The tube is spirally wound onto a cylindrical mandrel. To do this, you can take a log or a large diameter pipe.

When winding the coil, it is important to keep track of the turns:

- in order to provide the best contact between the heating surface of the tube and the heated water, the loops should not touch each other;

- you should not do the winding with excessive force, then it will not be easy to remove the coil from the mandrel.

- The number of turns on the coil is calculated from the volume and height of the tank.

Thermal insulation

The outside of the tank must be covered with a layer of insulation. It is necessary to increase efficiency and reduce heat losses. For insulation of the container, polyurethane foam, mineral wool or any other heat-insulating material that is attached to the base with wire, glue or strip ties is suitable. For a neat appearance, it is better to cover the tank body with thin sheet metal or foil insulation.

You can also insulate the tank using another container with a larger diameter. To do this, a do-it-yourself boiler is inserted into a large tank, and the wall is filled with insulating material or foam, according to the principle of a thermos.

Installation

The assembly of a self-made boiler is carried out after the preparation of all the components:

The assembly of a self-made boiler is carried out after the preparation of all the components:

- a coil in the center or along the walls is mounted inside the tank, pipes are soldered to its inlet and outlet pipes;

- for a vertical boiler, supports are welded to the bottom, for a hinged device - “ears” loops;

- the heating element is installed;

- the boiler is tightly closed with a lid;

- connecting the coil according to the scheme for manufacturing an indirect heating boiler with your own hands to the heating system circuit;

- connection of the inlet / outlet pipe for water;

- piping to the kitchen or bathroom at the point of draw-off.