What are the feed dispensers for cattle farms and how to choose the right model for your farm

One of the most time consuming jobs in agricultural enterprises is animal feeding. By installing feed dispensers for a cattle farm, animal care is greatly simplified, and business costs are significantly reduced.

One of the most time consuming jobs in agricultural enterprises is animal feeding. By installing feed dispensers for a cattle farm, animal care is greatly simplified, and business costs are significantly reduced.

Feed dispensers for cattle farms and their types

When choosing a model of a feeder, one should take into account a possible increase in livestock or redevelopment of the room in which the animals are kept.

A large agricultural holding will need a spacious and multifunctional automatic feed dispenser capable of feeding hundreds of cattle in one pass to solve problems.

A large agricultural holding will need a spacious and multifunctional automatic feed dispenser capable of feeding hundreds of cattle in one pass to solve problems.

After determining the performance, it is necessary to decide the issue of placing the mechanism and choose between stationary and mobile.

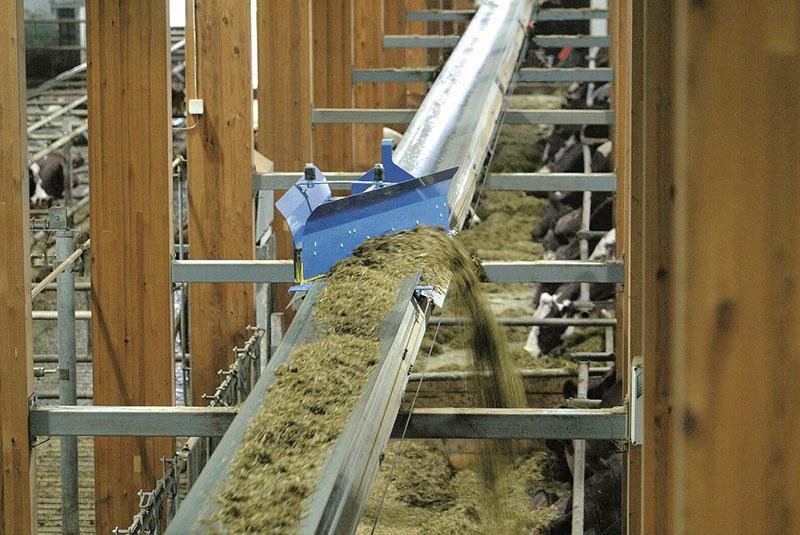

Stationary models

A stationary dispenser is installed in a room where animals are kept. It is a container at the bottom of which a conveyor is mounted. Feed enters the stationary dispenser from a special hopper. After loading the container, the electric motor is turned on and the conveyor moves the contents throughout the room. Stationary models differ among themselves by the type of conveyor. They can be scraper, tape, as well as tape and strip and tape and chain.

A stationary dispenser is installed in a room where animals are kept. It is a container at the bottom of which a conveyor is mounted. Feed enters the stationary dispenser from a special hopper. After loading the container, the electric motor is turned on and the conveyor moves the contents throughout the room. Stationary models differ among themselves by the type of conveyor. They can be scraper, tape, as well as tape and strip and tape and chain.

Stationary with belt conveyor

A simple and inexpensive unit with a minimum of components is appreciated by farmers for its ease of maintenance, versatility and maintainability. In fact, it is a storage hopper and conveyor at the bottom.

A simple and inexpensive unit with a minimum of components is appreciated by farmers for its ease of maintenance, versatility and maintainability. In fact, it is a storage hopper and conveyor at the bottom.

The feed mixtures are poured into the hopper, the conveyor moves them in portions to the hole through which the contents fall on the second conveyor - a double-sided belt stretched through the entire hangar where the animals are kept. The drive mechanisms start the electric motors.

The amount of feed in the conveyor belts is easy to meter by increasing or decreasing the outlet in the hopper and adjusting the speed of the conveyors.

One of the most popular models of tape feed dispensers TVK-80B is equipped with an electric motor with a power of 5.5 kW and is capable of serving up to 62 head of cattle, giving out 38 tons of feed per hour.

Benefits of tape dispensers:

- reasonable prices for equipment and installation;

- the ability to deliver both feed and bedding materials;

- collapsible system.

The collapsible principle allows you to assemble both the simplest conveyor, switched on manually, and the whole complex with automatic mixing of feed mixtures according to various recipes.

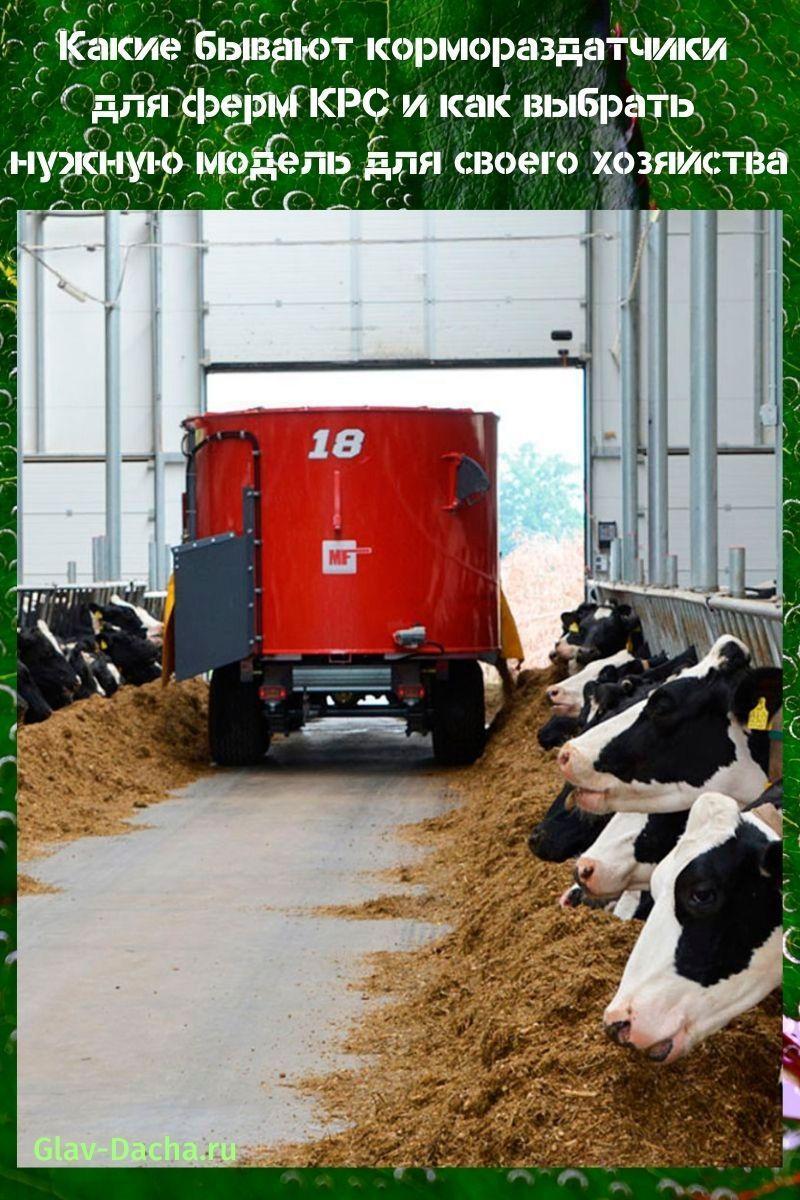

Mobile feed dispensers for cattle farms

Mobile feed dispensers are used to dispense both dry and succulent plant feed. Dispensing is carried out into the feeders directly from the bunker, bypassing the conveyor.

Mobile feed dispensers are used to dispense both dry and succulent plant feed. Dispensing is carried out into the feeders directly from the bunker, bypassing the conveyor.

Mobile units have a similar design and consist of 4 units:

- frames on wheels for moving;

- storage hopper;

- mixer for complex compositions;

- dispenser.

The device is a trailer for a truck, walk-behind tractor or a tractor.Other models have an electric motor for moving around the hangar.

In some cases, self-propelled feeders can move on rails, tracks or have a suspended installation. The use of this technique is limited to one room.

Mounted feeders

Mounted models are made in the form of a vertical, expanding upward hopper with a volume of 1–3 cubic meters, in which an auger with knives is installed. Designed for chopping straw, hay and silage, and mixing them with silage or forage. Individual components do not lose their qualities, do not heat up, do not wrinkle and do not cake. At the exit, after grinding and mixing, a homogeneous mixture is obtained, which animals willingly eat.

Mounted models are made in the form of a vertical, expanding upward hopper with a volume of 1–3 cubic meters, in which an auger with knives is installed. Designed for chopping straw, hay and silage, and mixing them with silage or forage. Individual components do not lose their qualities, do not heat up, do not wrinkle and do not cake. At the exit, after grinding and mixing, a homogeneous mixture is obtained, which animals willingly eat.

One of the popular models is the Kuban MS-1.5 mounted feed dispenser with grinding and mixing functions, produced in Krasnodar, has a bunker volume of one and a half cubic meters, a vertical auger with 5 knives and the ability to connect to an electric motor up to 7 kW or to a class 2 hitch from a tractor with a power take-off shaft.

One of the popular models is the Kuban MS-1.5 mounted feed dispenser with grinding and mixing functions, produced in Krasnodar, has a bunker volume of one and a half cubic meters, a vertical auger with 5 knives and the ability to connect to an electric motor up to 7 kW or to a class 2 hitch from a tractor with a power take-off shaft.

Spiral Feeders for Poultry

The spiral feeding system is used to automate the distribution of feed in poultry farms. It is convenient for broilers on the floor, for raising young stock with rationed feeding or turkeys. The devices are suitable for any configuration of poultry houses.

The spiral feeding system is used to automate the distribution of feed in poultry farms. It is convenient for broilers on the floor, for raising young stock with rationed feeding or turkeys. The devices are suitable for any configuration of poultry houses.

The spiral feeder consists of three main units:

- hopper with a volume of about 100 liters,

- drive mechanism;

- spiral conveyor.

The feeders are attached to pipes, the height of which is adjusted to the size of the bird. During unloading of poultry, cleaning in the poultry house or other manipulations, the dispenser is raised to the very ceiling of the room.

Features of the distribution of feed on pig farms

A significant proportion of the pigs' diet is wet and semi-liquid feed. This feature must be taken into account when designing pigsties and installing feeding equipment.

A significant proportion of the pigs' diet is wet and semi-liquid feed. This feature must be taken into account when designing pigsties and installing feeding equipment.

On pig farms, they mainly use stationary models mounted directly in or above the feeders.

The first type feeders for pig farms have considerable advantages:

- save space;

- have a reliable and lightweight design;

- allow you to quickly remove feed residues and keep the trough clean.

The main disadvantages are:

- the mixer prevents the animals from completely eating the feed;

- the amount of food waste is increasing;

- Moving food along the feeding front increases the risk of spreading infections.

Devices with a dispenser above the feeder are devoid of the listed disadvantages, but they have their own:

- larger and more metal-intensive dimensions;

- complex care of feeders;

- reduced degree of reliability.

Farms have appreciated and actively use feed dispensers:

- RS-5A; KS-1.5; IES-1.7; KPS-0.18 - electric models for mixing and dispensing wet and semi-liquid feed;

- automatic complex RKA-2000, designed to service more than 2 thousand heads;

- model РКА-60/600 is designed for rationed feeding of 60 queens and more than 600 piglets according to a given program;

- RKS-3000 is a powerful and productive complex that accepts and distributes dry, coarse, dry and juicy feed mixtures. Able to serve up to 3 thousand pigs. Fully electrified - 3 electric motors drive the feed dispenser, platform and conveyor.

How to choose a mixer feeder

Multifunctional technology has always been valued over units capable of performing only one operation. In agriculture, such devices are considered indispensable. Thanks to them, it is possible to significantly reduce labor costs and reduce costs. Therefore, feeders with the function of mixing and grinding feed have practically displaced monofunctional models from the market. But the choice of such a mechanism should be approached carefully.

Multifunctional technology has always been valued over units capable of performing only one operation. In agriculture, such devices are considered indispensable. Thanks to them, it is possible to significantly reduce labor costs and reduce costs. Therefore, feeders with the function of mixing and grinding feed have practically displaced monofunctional models from the market. But the choice of such a mechanism should be approached carefully.

A quality mixer should:

- optimally grind any ingredients;

- mix gently, excluding the mass sticking into lumps;

- accurately weigh and accurately dose the contents;

- be easy to operate and maintain;

- to match the size and configuration of the farm.

When choosing a mixer-feeder for cattle farms, it is necessary to consider:

- is he able to work with the existing feed base - rolls, compound feed, bales and loading equipment;

- how long does it take to prepare the feed;

- in what sequence is it recommended to load the components of the mixture;

- how much it is necessary to fill the hopper for normal mixing of ingredients;

- whether this model is intended for industrial use;

- whether the unloaded leftovers remain after distribution and in what quantity.

For large agricultural holdings, they use mixer models with two vertical screws - SRK - 12V, 14V, 16V, 21V. They successfully combine the latest technology with simple design and a reliable vertical mixing system.

In these models, the hopper is made by multiple folds. This design is characterized by the absence of seams and increased rigidity. Thus, the service life is increased by 15–20%. Among themselves, the models differ in tank volume, dimensions and load capacity.

In these models, the hopper is made by multiple folds. This design is characterized by the absence of seams and increased rigidity. Thus, the service life is increased by 15–20%. Among themselves, the models differ in tank volume, dimensions and load capacity.

Terms of use

Personnel trained and familiar with safety precautions are allowed to work on feed dispensers for cattle farms. These devices contain a large number of sharp, cutting and moving parts and can cause accidents and injuries.

Personnel trained and familiar with safety precautions are allowed to work on feed dispensers for cattle farms. These devices contain a large number of sharp, cutting and moving parts and can cause accidents and injuries.

The unit is preliminarily run at idle, without loading feed. Also check for the presence and correct installation of protective guards and grounding.

During operation, the equipment is regularly cleaned of feed residues and, if necessary, disinfected. This is especially true for semi-liquid, perishable ingredients. Dispensers of dry food practically do not need disinfection.

Maintenance should be done regularly - lubrication, adjustments and replacement of defective parts.

Feed dispensers for cattle farms are an indispensable element of agricultural automation. A well-chosen unit is able to solve many problems - to adjust the process of feeding animals, taking into account their age and developmental characteristics, to reduce the share of unskilled manual labor and to free up personnel for more creative and responsible tasks.