How is the roof of the roof with a profiled sheet with your own hands

The developer undertakes part of the work. Roofing work is responsible, but not complex. Covering the roof with a profiled sheet with your own hands is a feasible task for a craftsman. You just need to follow the sequence of actions and follow simple rules.

The developer undertakes part of the work. Roofing work is responsible, but not complex. Covering the roof with a profiled sheet with your own hands is a feasible task for a craftsman. You just need to follow the sequence of actions and follow simple rules.

Roof from corrugated board, instructions for the selection of material

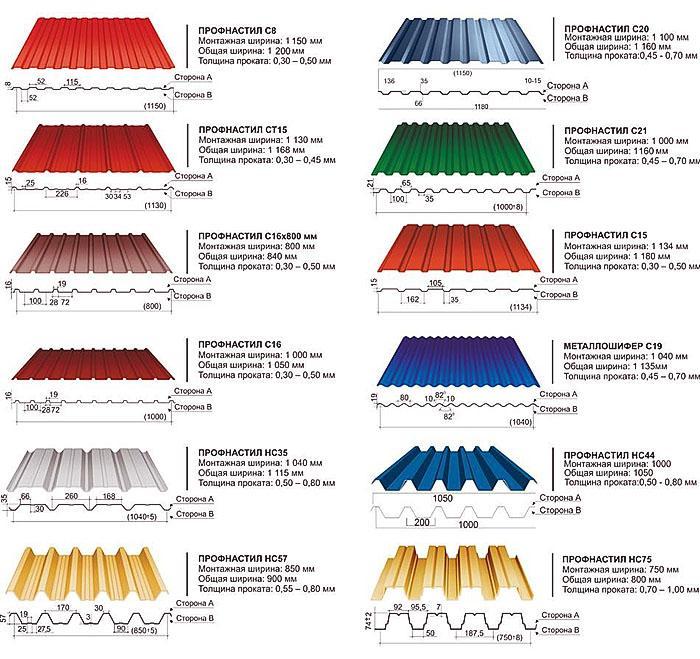

The purpose of the material is determined by the technical properties of the letter indexing:

- Н (load bearing) - different corrugation height 45–160 mm, sheet thickness, reinforced with additional longitudinal ribbing, withstands extreme loads;

- NS, PK (universal, roofing) - profiled grooves along the shelves allow to withstand snow and wind loads without restrictions on the windage of the roof, height 20–45 mm;

- C (wall) - applies with restrictions: the height of the shelves is taken at least 20 mm, the lathing becomes more frequent or solid.

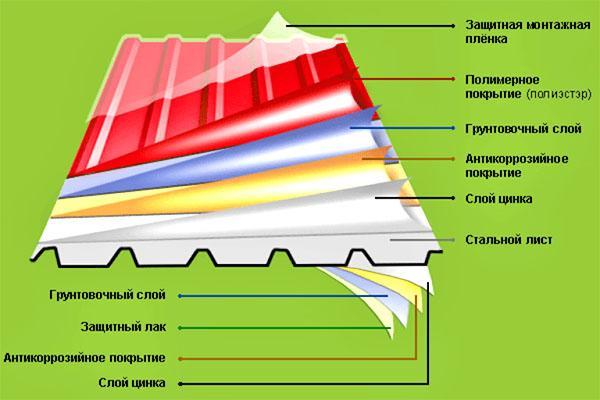

The choice of this type of roofing is stimulated by the advantages:

- duration of operation with minimal maintenance;

- polymer coating lasts up to 50 years, warranty period up to 20 years.

- strength with low weight;

- the breadth of the color palette;

- the availability of roofing roofing with a profiled sheet with your own hands.

Of the shortcomings, the drum effect is recognized as significant - the transmission of the sound of falling drops with possible amplification. Laying a layer of insulation eliminates the resonance defect.

Roofing from corrugated board, technology

We choose a corrugated sheet, the reference point is the steepness of the rafter angle. The device of the roof of the roof with a profiled sheet with your own hands gives scope in the selection of material. It is used as a roof and wall profile with a corrugation height of at least 20 mm. And for awnings over the porch, the flat covering of utility blocks is less acceptable.

We choose a corrugated sheet, the reference point is the steepness of the rafter angle. The device of the roof of the roof with a profiled sheet with your own hands gives scope in the selection of material. It is used as a roof and wall profile with a corrugation height of at least 20 mm. And for awnings over the porch, the flat covering of utility blocks is less acceptable.

In order to reduce the cost of construction, a combination of roofing and wall profiled sheet with the same width of the corrugation is allowed. In areas with a change in geometry in the direction of decreasing the angle, a mismatch in the height of the profile is allowed. How to cover the roof - the developer decides.

Scratches, other damage to the anti-corrosion coating are treated with a protective coating immediately, during storage

The general requirement is to limit the reduction in angle. For flat roofs of auxiliary buildings, the limit for reducing the angle is 8 °, for residential - 10 ° with the device of a solid board sheathing or from OSB sheets.

The crate is discharged from an angle exceeding 15 °. Discharge step:

- S-20 - 0.2–0.3 m;

- S-21 - 0.3-0.5 m;

- NS-35, S-44 - 0.5 m to 15 °, more than 15 ° - up to 1 m; permissible load 0.43–0.76 t / m2.

Key nodes of corrugated roofing

The rafters reliably leaned on the Mauerlat, but the installation will wait until the vapor-conducting membrane is laid and glued. Removal of moisture will extend the service life of the insulation, the film will not allow a draft to blow out small fractions of the insulation cake from mineral wool.

The rafters reliably leaned on the Mauerlat, but the installation will wait until the vapor-conducting membrane is laid and glued. Removal of moisture will extend the service life of the insulation, the film will not allow a draft to blow out small fractions of the insulation cake from mineral wool.

A counter lattice is attached to the nails on top of the membrane. The purpose of the 20–40x50 timber is to create a ventilation gap for ventilating the insulation and roofing. In frost and heat, the breeze will reach the ridge.Condensation will not form on the inside of the sheets. The metal profile of LSTK is not very common in private construction. The technology of work is identical, therefore, the type of material is not distinguished separately.

Wooden parts are nailed down. Fixing OSB boards is permissible with self-tapping screws.

According to the tabular dimensions, the frequencies of laying the crate were determined, we nail the necrombled boards, the slab. The joints are arranged in the center of the counter-lattice beam. Mostly coniferous sawn timber is purchased.

Installation of the 3 listed elements is carried out in stages from bottom to top, as shown in the photo. It is necessary to achieve the most even surface without sharp changes in height at the joints.

Aspen and Birch tree rejected - one is short-lived and weak: it will break under the foot during installation, the other is subject to excessive warping and twisting.

Fastening the profiled sheet on the roof

Preparing fasteners for corrugated board. You will need anodized self-tapping screws for metal with a drill at the end and sharpened with fine threads. A rubber gasket is required under the cap. The force is easier to apply to the hex head. The cross recess is more difficult to hit.

Preparing fasteners for corrugated board. You will need anodized self-tapping screws for metal with a drill at the end and sharpened with fine threads. A rubber gasket is required under the cap. The force is easier to apply to the hex head. The cross recess is more difficult to hit.

Average consumption - 7.5 pcs per 1 m2... Self-tapping screws 4.8x30 for sheets and 4.8x50 (60) for additional elements will be required. From the tool you will need screwdriver with two accumulators and a bat, angle grinder with a disc 1 mm thick for cutting along lengths, corners, flanging of end pieces.

Experts argue: how to fix it? The self-tapping screw in the lower shelf holds the profiled sheet more reliably. The upper mount is safe in terms of leaks into the under-roof space when melt water stagnates on a gentle slope. Combinations with fasteners are possible. Manufacturers insist on fastening in the first way: in deflection.

For a vertically mounted self-tapping screw, the sealing gasket evenly protrudes from under the head by 1 mm in a circle.

On the ridge and cornice, self-tapping screws are placed across the wave, in the middle of the sheet - at a distance into each board of the sheathing. The joints of the sheets are fastened through 2 waves. Mark broken screws with beacons to close the hole without a lot of searching.

Installation of a profiled sheet on the roof, instructions

How many vertical sheets are needed is up to the builder. Ordering a full-size sheet without subsequent connections is economically justified. But you will need to wait for delivery.

How many vertical sheets are needed is up to the builder. Ordering a full-size sheet without subsequent connections is economically justified. But you will need to wait for delivery.

Standard length sheets are stacked in two ways:

- along the cord in order, starting from the bottom;

- in an unmistakable way according to the scheme as in the photo.

The first sheets of corrugated board are attached to one self-tapping screw in the middle. An overhang of 4–5 cm beyond the lowest point of the rafter is necessary to optimize natural ventilation and install the cornice. Then the set is fixed to each other after 0.5 m. After a control check of the evenness of laying along the roof overhang, the profiled sheets are attached finally.

When the angle of inclination of the roof is less than 15 ° and the depth of the corrugation is less than 20 mm, the adjacent sheet is superimposed on 2 waves of the previous one. Increasing the angle allows only 1 wave to be covered. If there is a drainage groove in the bottom shelf, cover it.

The top row overlaps the previous one. The amount of overlap relative to the steepness of the roof:

- up to 15 ° - 200 mm;

- up to 30 ° - 150 mm;

- over 30 ° - 100–150 mm.

Even in soft shoes, you cannot step on the crest of the corrugated board - it will bend.

Registration of abutments on the roof from corrugated board

The adjoining of the corrugated board to the wall prevents moisture leakage, blowing snow under the corrugated board at the junction. The corner piece is produced with a polymer coating 2 m long, galvanized 2.5 m.

The adjoining of the corrugated board to the wall prevents moisture leakage, blowing snow under the corrugated board at the junction. The corner piece is produced with a polymer coating 2 m long, galvanized 2.5 m.

The abutment bar for the corrugated board is fixed through the upper wave. This is where the long fasteners come in. It is advisable to purchase a complete set of components from one manufacturer: at least there will be no color difference.

It is difficult to perform the first connection to the pipe on the roof made of corrugated board. The apron wings of the chimney bypass are adjusted, tightly covering the pipe. The upper edge is pressed by tightening the screws into the dowels.

It is difficult to perform the first connection to the pipe on the roof made of corrugated board. The apron wings of the chimney bypass are adjusted, tightly covering the pipe. The upper edge is pressed by tightening the screws into the dowels.

The adjacent profiled sheet will have to be reinstalled - a forced manipulation in the name of preventing leakage. Without installing a porous seal that copies the profile, this action will turn out to be a half measure. And the indispensable sealing of the vertical seam.

The location of the pipe at the bottom of the roof dictates the need to install a snow shield.

Eaves overhang of a roof made of corrugated board

Framing the lower overhang will prevent the wood from getting wet, the insulation disheveled, and will give a strict look to the structure. We present a choice of 3 equivalent design options for the overhang on the rafter legs.

Framing the lower overhang will prevent the wood from getting wet, the insulation disheveled, and will give a strict look to the structure. We present a choice of 3 equivalent design options for the overhang on the rafter legs.

Installation starts from the bottom of the wall. In the first two versions, the soffit as a frontal board is stiffer, not limited by vertical dimensions. Self-tapping screws with a hexagon are not needed.

For completeness, it remains to install an end plate to protect the extreme rafters with an overhang of the profiled sheet. Fastening to the rafter is carried out along the bottom edge with an indent of 25 mm.

For completeness, it remains to install an end plate to protect the extreme rafters with an overhang of the profiled sheet. Fastening to the rafter is carried out along the bottom edge with an indent of 25 mm.

Roof ridge made of profiled sheet

The gap of the upper edge of the intersection of the roof slopes is covered with a ridge strip. The shape of the ridge allows air circulation to ventilate the roof space.

The gap of the upper edge of the intersection of the roof slopes is covered with a ridge strip. The shape of the ridge allows air circulation to ventilate the roof space.

Installation sequence:

- by the size of the shelf width (100–300 mm) double-sided tape is glued;

- a porous seal is installed;

- according to the marking, 50 mm is cut off from the support bar and the vertical stand, the upper bend is cut into the depth, the ends of the profile are bent at right angles (or a standard plug is installed);

- sealant is applied to the seal;

- the ridge is installed with an approach to the end plate;

- fastening with self-tapping screws.

The roof, assembled from a profiled sheet with your own hands, acquired the appearance of a single whole. Congratulations.

The roof, assembled from a profiled sheet with your own hands, acquired the appearance of a single whole. Congratulations.

I have a garden house with corrugated board. True, he did not do it himself, but the guys from Terem built it for me, and they did it right on time. And you know I like professional flooring, good material.