Well submersible pump - special requirements, types of equipment

The rise of water from the well is possible only with a pump. Well submersible pump must meet the conditions - to raise the liquid to a given height at the required flow rate, be safe and reliable. An informed choice of a pump can be made, knowing the features of different types of equipment, operating conditions.

The rise of water from the well is possible only with a pump. Well submersible pump must meet the conditions - to raise the liquid to a given height at the required flow rate, be safe and reliable. An informed choice of a pump can be made, knowing the features of different types of equipment, operating conditions.

Technical parameters of water extraction from wells

- well depth;

- static mirror level;

- dynamic level - decrease during pump operation can be 3-8 meters;

- flow rate - water inflow per unit of time from the horizon.

Using this data, it is required to calculate the maximum head and pump capacity. The productivity should not exceed the well production rate.

High performance will cause frequent operation of protection against "dry running", can lead to the loss of the water horizon due to changes in the movement of the source.

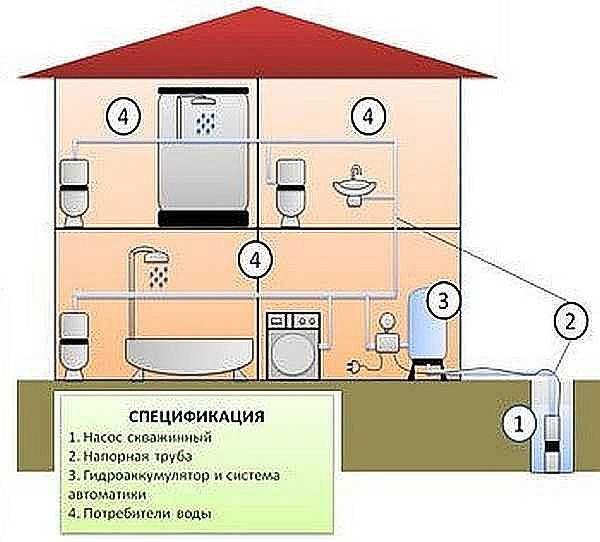

Submersible head well pump must ensure the vertical rise of water from the well and supply to the container. If the battery is at a distance, every 10 meters of horizontal pipe is equal to 1 meter of head. It is necessary to take into account the loss for resistance and bending of 20%, and add 10-30 m to create pressure in the pipe. Sum all measurements, this is the required minimum pump head.

The operating capacity of a submersible borehole pump is selected based on a flow rate of 300 l / h per person. By using a water reservoir, the consumption can be reduced. Peak loads will be compensated for by lowering the level in the battery.

Types of submersible borehole pumps

There are several types of submersible pumps that differ in their operating principle. The following devices are often used:

There are several types of submersible pumps that differ in their operating principle. The following devices are often used:

- centrifugal;

- screw;

- vibrating.

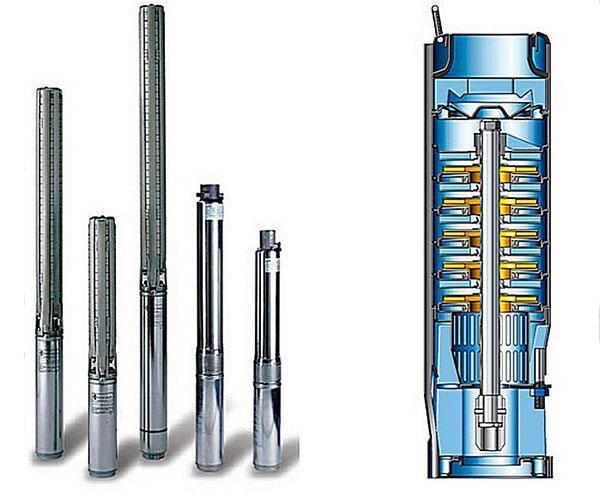

The most widely used centrifugal submersible pump. The impellers are located in a sealed housing on the shaft, driven by a built-in electric motor. The performance and head of the apparatus depend on the number of impellers on the shaft. The wheels are made of special materials such as polycarbonate, steel or noryl. The longer the body, the more wheels in the structure, the higher the engine power. In this case, a casing pipe with a cross section of 120 mm is enough to accommodate a pump in it.

The equipment in the well must have increased reliability. The submersible pump automation provides protection against electrical breakdown, overheating and dry start. The leader and developer of submersible pumps is the Danish company Grundfoz. SP, SQ series are designed for installation into the wells. Well submersible pump price Grundfos at least 30 thousand rubles. But the pump is reliable, durable, it can pump even muddy water from a depth of 50 m.

The "Aquarius" pump will cost three times cheaper. He is not afraid of a suspension of sand up to 180 g / m3, voltage drops. But it can lift water from a height of up to 10 meters.

In circulation pumps, head and capacity are inversely related. The lower the water flow, the higher the pressure.

Submersible screw pumps

The presence of an internal thread on the stator and the rotor scroll of the pump allow very dirty water to be lifted in a spiral. The pump is used to create a clean bed in the well chamber when pumping out the first portions of water. But further use is unprofitable, since the efficiency of the apparatus is below 65%, and it is irrational to use it in wells with clean water.

The presence of an internal thread on the stator and the rotor scroll of the pump allow very dirty water to be lifted in a spiral. The pump is used to create a clean bed in the well chamber when pumping out the first portions of water. But further use is unprofitable, since the efficiency of the apparatus is below 65%, and it is irrational to use it in wells with clean water.

With an increase in the number of revolutions, screw pumps increase productivity, the head remains unchanged.

Submersible screw pumps for water can be purchased from the Vodoley company of the BTsPE series. The devices are compact; installation in a 110 mm well is possible. You can buy the Belarusian model "Belamos". The Unipump pump is much more expensive than the above-mentioned devices, but surpasses them significantly in terms of performance.

Vibrating Submersible Pumps

The vibrating pump is so called because of the vibrations of the membrane under the influence of electromagnetic forces of alternating current of 50 Hz. Since the poles change 50 times per second, the number of oscillations is 2 times greater. At the same time, the tremor of the case is caught, and the entire apparatus is called vibration. The pump includes the following units and parts:

The vibrating pump is so called because of the vibrations of the membrane under the influence of electromagnetic forces of alternating current of 50 Hz. Since the poles change 50 times per second, the number of oscillations is 2 times greater. At the same time, the tremor of the case is caught, and the entire apparatus is called vibration. The pump includes the following units and parts:

- The pump drive is represented by an electromagnet representing a U-shaped core with a winding in a jacket made of epoxy resin - a compound.

- The vibrator is an anchor with a fixed rod with a rubber shock absorber. The shock absorber is connected by a rubber sleeve, which performs an insulating function and fixes the stem.

- The rod is a rod that goes into the water chamber and is fixed from the wet side.

- Water suction chamber with inlet and outlet nozzles.

- Adjusting washers. The more, the higher the pump performance. With their help, the amplitude of the piston movement is changed.

- Rubber gaskets act as a shock absorber and check valve.

Structurally, there are models with upper and lower water intake. The upper suction connection allows the use of cleaner, silty water.

The design was developed in the last century in the Soviet Union, it is used in the CIS countries, represented by pumps Trickle, Kid, Aquarius. The ability of these devices to handle dirty water is used to clear the bottom of the well from silt. In this case, a pump with a bottom intake should be used. Once the well is cleaned up, the rubber parts will have to be replaced, but this costs much less than hiring a team of workers.

What is the difference between a submersible drainage pump and a borehole pump

Submersible pumps differ in function. Apparatus designed for lifting clean cold water, for hot agents and for pumping liquids with mechanical and other impurities. Borehole or drainage pumps can be used to remove dirty water.

Submersible pumps differ in function. Apparatus designed for lifting clean cold water, for hot agents and for pumping liquids with mechanical and other impurities. Borehole or drainage pumps can be used to remove dirty water.

The submersible drainage pump has large dimensions, openings for the intake, sometimes it is equipped with a grinder. They are used to remove waste, pumping water from flooded basements, canals, wells or waste storage.

Submersible well pumps capable of pumping liquid from a depth of up to 20 meters, surface installations cannot cope with such a task.

The design of submersible drainage pumps is simple, but pumping special compositions requires special internal and external protection. Therefore, all drainage pumps can work on the cold agent, and the buildup of hot drains is trusted by foreign famous brands - Grundfoz, Park, Karcher. Their pumps have a thermal insulating layer so that the engine heats up more slowly, a channel design is made. To pump cold drains, the Malysh and Caliber devices are used. In any case, the weak point of the drain pumps is overheating of the motors.

Installation of a submersible drainage pump is simple. The pump is installed on a plane and a hose is put on the discharge line. Connect, check the presence and operation of the float switch. Install the device by lowering it to the bottom or hanging it at a certain height.