Instructions for choosing and self-installation of poles for a country fence

The fence is one of the simplest and most reliable access control structures, which not only delineates the boundaries of the site, but gives the owner a sense of comfort and security on their territory. The main bearing element of any fence is the fence posts. The reliability and decorative component of any fence depend on the appearance, quality of the material. Do not forget about the correct installation of the supporting structure, which determines the durability of the fence. This publication will talk about how to choose and install the fence posts with your own hands, without involving expensive specialists and heavy construction equipment.

The fence is one of the simplest and most reliable access control structures, which not only delineates the boundaries of the site, but gives the owner a sense of comfort and security on their territory. The main bearing element of any fence is the fence posts. The reliability and decorative component of any fence depend on the appearance, quality of the material. Do not forget about the correct installation of the supporting structure, which determines the durability of the fence. This publication will talk about how to choose and install the fence posts with your own hands, without involving expensive specialists and heavy construction equipment.

Read also our article: polycarbonate fence - simple and fast!

Supports for fencing: types and characteristics of material

Today, the domestic construction market offers the widest range of supporting elements and materials for their manufacture. You can make do-it-yourself fence posts from wood, metal, concrete blocks and bricks. In modern construction practice, supports for lightweight fences made of a combination of composite materials and concrete are widely used. Consider the main characteristics and installation features of each supporting structure in more detail.

Wood

- oak;

- larch;

- acacia;

- Pine;

- spruce;

- fir.

According to experts, it is categorically impossible to use wood for supporting structures, such as: birch; aspen; beech; alder.

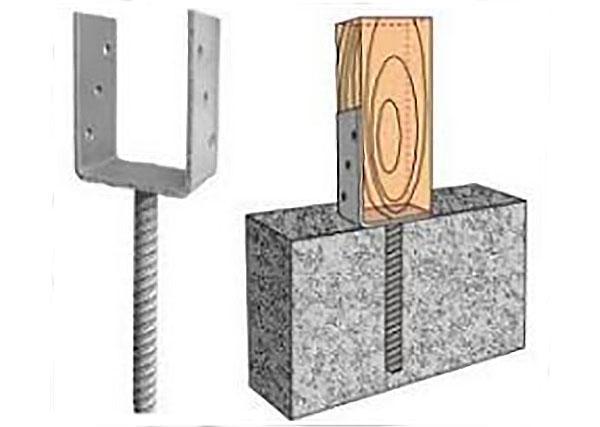

The main advantage of wooden fence posts is the possibility of self-installation. The disadvantage is the fragility of wood, susceptibility to moisture and high temperatures, rotting, infection with a fungal infection. The average "lifespan" of wooden poles is 2-4 years. To increase the service life of wood, various impregnations are used based on antiseptics and copper sulfate, annealing of the top layer, and resinification.  One of the most effective methods of installing wooden posts for fences is mounting on a crutch - a metal support structure that excludes contact of wood with the soil.

One of the most effective methods of installing wooden posts for fences is mounting on a crutch - a metal support structure that excludes contact of wood with the soil.

The choice of supporting elements made of wood is justified in the case of using a similar material, a chain-link or mesh made of modern polymers as a building envelope.

Metal

Today, metal fence posts are quite popular with developers. Compared to wood, metal is more reliable, durable, perfectly withstands high lateral loads, it is combined with wooden fencing, steel mesh, corrugated board, etc. wall thickness 1.5-2 mm. The main advantages of metal load-bearing elements are:

Today, metal fence posts are quite popular with developers. Compared to wood, metal is more reliable, durable, perfectly withstands high lateral loads, it is combined with wooden fencing, steel mesh, corrugated board, etc. wall thickness 1.5-2 mm. The main advantages of metal load-bearing elements are:

- the ability to install almost any fasteners on them by welding or threaded connection;

- use of various installation techniques.

The disadvantages of metal pipes are: high cost, low corrosion resistance and possible deformation due to temperature changes. To increase the "life" of the metal requires regular painting, rust removal, protection of the internal cavity from moisture.

Concrete

Concrete fence posts of proper quality are the best solution for strong and high "blind" fences. Concrete structures have a number of advantages, among which the most significant can be considered: high strength, durability, low maintenance requirements. The main disadvantage is the high cost. Today, there are several ready-made proposals on the domestic market of building materials:

Concrete fence posts of proper quality are the best solution for strong and high "blind" fences. Concrete structures have a number of advantages, among which the most significant can be considered: high strength, durability, low maintenance requirements. The main disadvantage is the high cost. Today, there are several ready-made proposals on the domestic market of building materials:

- Reinforced concrete beams.

- Supports with guides for fence plates.

- Decorative fence posts - cast concrete supports with various relief patterns.

- "Grape posts", which are perfectly used by our compatriots as load-bearing elements for lightweight enclosing structures.

Buying ready-made concrete pillars requires large financial investments, although all costs are justified by a long service life. That is why developers recommend making concrete supports on their own, using a standard polymer form as a matrix for pouring, which will not be difficult to buy.

Asbestos-cement pipe

Using this material as a support structure can be safely called an economical solution. Pipes made of this material are lightweight, have good strength characteristics, and do not corrode. However, for the installation of transverse lags to asbestos-cement pipes, the developer will need to use specialized fasteners, clamps and girths.

Using this material as a support structure can be safely called an economical solution. Pipes made of this material are lightweight, have good strength characteristics, and do not corrode. However, for the installation of transverse lags to asbestos-cement pipes, the developer will need to use specialized fasteners, clamps and girths.

In addition, the negative qualities of this material can be considered:

- Poor combination with wood, fence plates, metal profile fencing.

- Possibility of rupture under the influence of freezing water trapped in the pipe cavity.

To increase the strength characteristics and ensure greater durability, fill the cavity of the asbestos-cement supports with sand-cement mortar and install steel reinforcement inside.

Brick

Brick fence posts are durable and decorative, but require special knowledge and professional skills from the developer. Brick supports have an impressive mass, therefore, I require the mandatory creation of a foundation. The durability of brick supports remains in question, since it depends on the correct installation of the entire structure, the competent creation of the base, the drainage system, the presence of a cap that protects the masonry from moisture.

Brick fence posts are durable and decorative, but require special knowledge and professional skills from the developer. Brick supports have an impressive mass, therefore, I require the mandatory creation of a foundation. The durability of brick supports remains in question, since it depends on the correct installation of the entire structure, the competent creation of the base, the drainage system, the presence of a cap that protects the masonry from moisture.

Before creating the supporting elements made of bricks, careful studies of the depth of soil freezing, the location of groundwater, soil composition, etc. are required.

Based on the above, we can conclude that a fence with brick pillars is a rather expensive solution, especially if we take into account the services of specialists and the cost of delivering the material to the construction site.

There is one fairly simple and therefore popular method for creating brick supports. In place of the future support, a metal pipe is installed in the ground.

There is one fairly simple and therefore popular method for creating brick supports. In place of the future support, a metal pipe is installed in the ground.

Next, the formwork is placed to create a concrete parapet. After the concrete hardens, the pipe is lined with bricks, and the parapet is decorated with brick-like tiles.

Installation rules for fence supports

Despite the fact that self-installation of poles for fence - This is not the most time-consuming activity in construction, but you need to know and follow certain rules. A few recommendations from specialists for the installation of fence posts, regardless of the material used:

- Before creating, it is necessary to perform work on marking the perimeter of the fence, the location of the lags.To do this, between the extreme posts, you need to pull the cord at the level of the upper and lower crossbars.

- Determine the location of the posts based on the length of the fence. The optimal distance between the fence posts should be 2 to 3 meters.

- Drill support holes. The depth of the pillars depends on the type of soil. In sandy and rocky soils, the depth of the holes should be at least 1/3 of the height of the fence. On heaving soils, pits are made with a depth below the freezing point.

- The diameter and shape of the "cup" for the pole is calculated depending on the wind load, the installation method and the material of the support.

Next, we will consider the main points of installing the supporting elements of the fence made of wood, metal and concrete.

Installation of wooden support elements

Experts recommend using solid wood pillars with a diameter of 150 mm or more as extreme wooden supports in the perimeter. For supporting elements in the middle of the structure, logs with a diameter of 100 mm or more can be used.

Experts recommend using solid wood pillars with a diameter of 150 mm or more as extreme wooden supports in the perimeter. For supporting elements in the middle of the structure, logs with a diameter of 100 mm or more can be used.

Before installation, it is recommended to treat the pillars with an antiseptic, and wrap the end of the support element with several layers of roofing material.

Work order:

- In the ground, use a drill to prepare vertical holes of the appropriate diameter. The hole diameter should be twice the cross section of the column. The depth of laying a wooden post is 500 mm with a fence height of 1500 mm. By increasing the height of the fence, the depth of the support should also be increased.

- Provide drainage. At the bottom of the hole, a layer of sand, screenings or crushed stone should be poured.

- Place the support in the "glass" strictly vertically. Check the correct setting with a spirit level.

- Spin the support member in the hole with broken bricks.

Fill the space between the "glass" and the post with rubble, periodically ramming it with a crowbar or other convenient tool

Installation of concrete fence posts

Solid reinforced concrete supports for the fence are installed similarly to wooden ones, only instead of backfilling, the structure is filled with sand-cement mortar. For self-creation of concrete pillars, you can use concrete pouring of a special formwork for columns, which can be purchased relatively inexpensively at any major hardware store.

Solid reinforced concrete supports for the fence are installed similarly to wooden ones, only instead of backfilling, the structure is filled with sand-cement mortar. For self-creation of concrete pillars, you can use concrete pouring of a special formwork for columns, which can be purchased relatively inexpensively at any major hardware store.

Installation order:

- Assemble the 1 m high formwork on four sides. Next, collect only three sides, the fourth is not installed. The free space is used for pouring concrete.

- Secure the shields with slopes.

- Install a reinforcing structure inside the formwork.

- Pour horizontal layers of concrete into the mold.

Next, install the anchors to secure the fence.

Among our compatriots, typesetting posts for a fence are very popular, despite the fact that this solution is not budgetary. Support structures such as a constructor are assembled from special concrete blocks. The main difficulty is creating a foundation on which the material is laid.

Fence post blocks have a cavity. Installation of pillars of this design is quite simple: the blocks are stacked on top of each other, the cavities are reinforced and filled with concrete.

Fence post blocks have a cavity. Installation of pillars of this design is quite simple: the blocks are stacked on top of each other, the cavities are reinforced and filled with concrete.

Rules for the installation of metal support structures

For the installation of metal supports, two methods are used: concreting and driving.

For the installation of metal supports, two methods are used: concreting and driving.

- In the first case, a hole of the required depth is created in the ground with a drill. The diameter of the hole should slightly exceed the cross-section of the metal column. The post is vertically installed in the prepared hole. The space between the support and the walls of the "glass" is filled with concrete.

- The second option involves driving a support into a smaller hole with a sledgehammer. This method is used for light structures and only on heavy soils.

You should know that there is another effective way of concreting metal hollow pillars, which consists in the following: the pit is filled with concrete, after which a support is driven into it.This method provides a better fixation of the column in the ground.

One of the easiest (but not cheap) options for creating a support structure for a fence is to install screw fence posts.

One of the easiest (but not cheap) options for creating a support structure for a fence is to install screw fence posts.

Installation of supports of this design is quite simple, does not require special time and labor costs. The pile is simply screwed into the ground. The upper part of the support, on which the support structure will be installed, can have a round or square section.