Meatlider's greenhouse is the best helper for a good harvest

It is unthinkable to get a rich harvest of a wide variety of vegetables and berries in the zone of moderate farming without the use of protected ground. In recent years, Meatlider's greenhouse has strongly supplanted the position of traditional "tomato houses". Why is this absurd at first glance structure so won over the picky gardeners?

It is unthinkable to get a rich harvest of a wide variety of vegetables and berries in the zone of moderate farming without the use of protected ground. In recent years, Meatlider's greenhouse has strongly supplanted the position of traditional "tomato houses". Why is this absurd at first glance structure so won over the picky gardeners?

Features and benefits of the Mitlider greenhouse

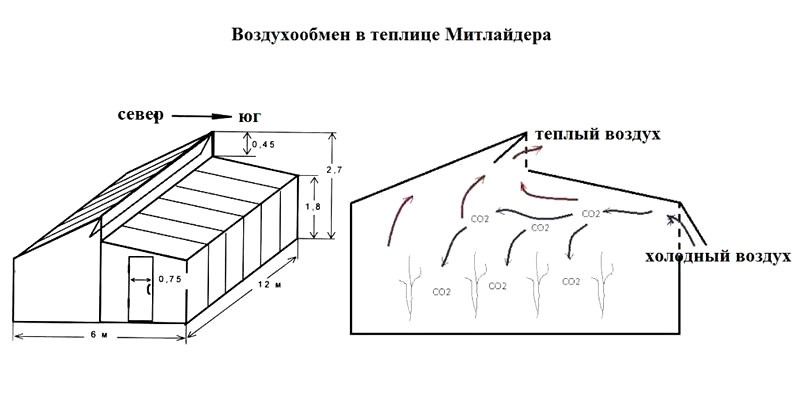

Thus, Jacob Meatlider, Ph.D. from the USA, solved the problem of overheating of greenhouses during the daytime. It is well known that one of the significant disadvantages of any protected ground structure is overheating of the air on hot days.

In tomatoes and cucumbers, which are most often grown indoors, at temperatures above 33–35 ° C, pollen becomes sterile, the ovaries crumble. If the bushes are kept at a temperature of 38–40 ° C for several hours, they will begin to wilt and shed their leaves. In this way, plants try to retain moisture in their tissues and survive. Doubt? Remember what a few desert vegetation looks like - a camel thorn in Asia, cacti and other succulents in the American continent. To preserve precious moisture, their leaves are reduced into thorns.

In tomatoes and cucumbers, which are most often grown indoors, at temperatures above 33–35 ° C, pollen becomes sterile, the ovaries crumble. If the bushes are kept at a temperature of 38–40 ° C for several hours, they will begin to wilt and shed their leaves. In this way, plants try to retain moisture in their tissues and survive. Doubt? Remember what a few desert vegetation looks like - a camel thorn in Asia, cacti and other succulents in the American continent. To preserve precious moisture, their leaves are reduced into thorns.

We will not wait for our tomatoes to grow thorns instead of leaves and we will carefully analyze the diagram, drawings and calculations for building a greenhouse according to Meatlider on our own. To begin with, we need paper, a ruler, a pencil and a site plan.

How Mitlider's greenhouse is built

Before going to the store, you need to choose the optimal place for installing the greenhouse, decide on the foundation, take into account all the pros and cons of various building materials.

Before going to the store, you need to choose the optimal place for installing the greenhouse, decide on the foundation, take into account all the pros and cons of various building materials.

Choosing a location for a greenhouse

Few crops are able to withstand a lack of light, and in a greenhouse, the sun's rays are partially absorbed by polycarbonate, polyethylene or glass, which quickly becomes covered with dust. Therefore, the place for future construction should be well lit throughout the day. Only partial shading in the early morning or late afternoon is allowed.

Few crops are able to withstand a lack of light, and in a greenhouse, the sun's rays are partially absorbed by polycarbonate, polyethylene or glass, which quickly becomes covered with dust. Therefore, the place for future construction should be well lit throughout the day. Only partial shading in the early morning or late afternoon is allowed.

The second important point is the landscape of the site. It should be as flat as possible. Even a small height difference is undesirable. If the entire site is located on a slope, you will have to go for additional costs - carefully level the site or spend on a higher and more solid foundation.

The second important point is the landscape of the site. It should be as flat as possible. Even a small height difference is undesirable. If the entire site is located on a slope, you will have to go for additional costs - carefully level the site or spend on a higher and more solid foundation.

The most unfortunate decision is the arrangement of a greenhouse on the northern slope. Such places are less warm and illuminated. The energy efficiency of the greenhouse according to Meathlider will be noticeably lower, and during periods of returnable and early autumn frosts, plants may freeze.

It is also undesirable to choose lowlands on peatlands. On average, the soil and air in these places are 2-3 degrees colder.

Greenhouse base

When building a standard greenhouse, you can do without a foundation.If the area is flat, does not flood during high water, the lower strapping of the aluminum frame is placed directly on the ground. The design easily withstands small ground vibrations during freezing.

When building a standard greenhouse, you can do without a foundation.If the area is flat, does not flood during high water, the lower strapping of the aluminum frame is placed directly on the ground. The design easily withstands small ground vibrations during freezing.

Meatlider's greenhouse is somewhat more complicated. Even with slight distortions, the upper transoms will stop closing. Glass can crack in glazed buildings. Therefore, the simplest foundation for it is necessary - a point, from a bar or a concrete strip.

The following materials are suitable for a point foundation:

- wooden stakes of rectangular section;

- metal screw piles;

- concrete columns.

A drawing of a greenhouse according to Mitlider with the required dimensions must be prepared in advance so that the dimensions of the building do not have to be adjusted to fit the laid foundation.

The selected area is cleaned of debris, the topsoil is removed, and carefully leveled. Find the extreme points and mark them with pegs. Places for reference points are marked between them at an equal distance.

The frequency of the control points depends on the severity of the future structure, the material of the frame and the density of the soil. Piles or posts are installed at a distance of 0.5 to 1 m.

At the marked points, wooden stakes, pretreated with antiseptics, are driven in, screw piles or holes are dug under concrete posts. In the latter case, before building the frame, you will have to wait at least 2 weeks for the concrete to finally harden and gain strength.

The strip foundation for the greenhouse is built in the same way as for other buildings. A trench 25–40 cm deep is dug in the ground, formwork is mounted, covered with a layer of sand, the bottom is rammed, reinforcement is laid. When pouring the upper part of the foundation, holders for the metal frame are welded to the reinforcement.

Erection of the frame

For the frame material, choose a wooden beam or a metal profile. On hills, sandy soils and other dry places, a tree is suitable, in low-lying damp places, next to rivers, where the humidity is always high, it is more advisable to choose metal. In both cases, the base of the future building must be carefully treated with protective compounds.

For the frame material, choose a wooden beam or a metal profile. On hills, sandy soils and other dry places, a tree is suitable, in low-lying damp places, next to rivers, where the humidity is always high, it is more advisable to choose metal. In both cases, the base of the future building must be carefully treated with protective compounds.

Greenhouses made of wood by Meatlider are built with straight pitched roofs. The photo below shows a drawing and approximate dimensions of such a building.

Detailed device and attachment of the transom:

Construction and proportions of the upper part of the pediment. The standard slope of the northern slope is 35 °, the southern one is 20 °. The values can differ by several degrees in both directions.

A greenhouse made of wooden beams consists of the following parts:

- bottom strapping;

- longitudinal walls;

- gable walls;

- transoms;

- roof slopes;

- doors in the end parts.

The parts are connected with self-tapping screws, rectangular or T-shaped connecting plates or corner connectors.

Resinous tree species - pine, spruce, fir, are excellent for building a greenhouse. Resin emissions extend the life of the wood and have a positive effect on the microclimate of the "vegetable house".

Mitlider's arched greenhouse is built from a metal profile. It is not difficult to build it from the usual one, having slightly altered it. To do this, a vertical rectangle with a height of about half a meter and a length that matches the length of the greenhouse is mounted to the upper longitudinal crossbar. The southern part is sheathed to the bottom of this rectangle, and the northern part is sheathed to the top.

Mitlider's arched greenhouse is built from a metal profile. It is not difficult to build it from the usual one, having slightly altered it. To do this, a vertical rectangle with a height of about half a meter and a length that matches the length of the greenhouse is mounted to the upper longitudinal crossbar. The southern part is sheathed to the bottom of this rectangle, and the northern part is sheathed to the top.

In the difference in heights, transoms are attached to piano or ordinary window hinges. They can open both outside and inside the greenhouse. The first option is preferable, since the protruding vents will protect the plants from slanting rain or various debris.

Greenhouse cladding by Mitlider

The most popular today are the polycarbonate Mitlider greenhouses. This material is traded by a huge number of companies offering cutting and delivery of sheets to any place. Prices for it are quite affordable, the range of brands is huge.But not just any polycarbonate is suitable for our purposes.

The most popular today are the polycarbonate Mitlider greenhouses. This material is traded by a huge number of companies offering cutting and delivery of sheets to any place. Prices for it are quite affordable, the range of brands is huge.But not just any polycarbonate is suitable for our purposes.

For a greenhouse, you should choose polycarbonate with a protective layer from ultraviolet radiation. Otherwise, after a few years, the material will tarnish, become more brittle, and the throughput will greatly decrease.

In general, the thicker the polycarbonate sheet, the better its ability to retain heat. The material with a special inner layer to protect against condensation has good qualities.

An excellent option would be Mitlider's greenhouse, covered with polyethylene. The film is much cheaper than polycarbonate, it is easier to stretch it over the frame and replace it as needed. Reinforced or light-stabilized films will last longer, but any thick film will do.

An excellent option would be Mitlider's greenhouse, covered with polyethylene. The film is much cheaper than polycarbonate, it is easier to stretch it over the frame and replace it as needed. Reinforced or light-stabilized films will last longer, but any thick film will do.

An interesting and very profitable solution would be the device of a double layer of film - along the outer and inner edges of the timber. The double layer better protects against temperature extremes.

Combined options are very popular, when the roof is covered with more durable polycarbonate, and the side walls and gables are sewn up with polyethylene.

The beds in the greenhouse along the Meatlider are arranged in two or three rows, depending on the width of the building. For ease of maintenance, they are fenced with wood, plastic or straight slate. Arrange them in such a way that it is convenient to open and close the vents for ventilation.

Greenhouse according to Meathlider is an original, uncomplicated and very effective solution that allows you to grow the most capricious vegetables even in areas with a cold climate.