Biogas plant in a private house

According to statistics, half of private households in Russia are not supplied with gas, and even if the pipeline runs along the street, it is expensive to connect to it. Therefore, alternative sources have to be considered, such as a biogas plant. The device solves several problems at once - it gives out a cheap energy resource, recycles waste and provides fertilizers.

According to statistics, half of private households in Russia are not supplied with gas, and even if the pipeline runs along the street, it is expensive to connect to it. Therefore, alternative sources have to be considered, such as a biogas plant. The device solves several problems at once - it gives out a cheap energy resource, recycles waste and provides fertilizers.

How a biogas plant works

You should think about biogas production only with constant access to a large amount of biomaterial, in particular manure.

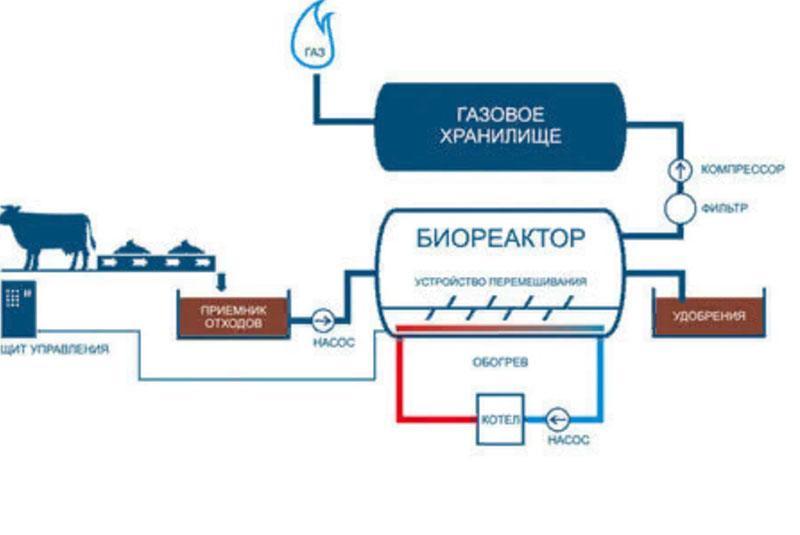

The biogas plant itself consists of:

- waste receiver;

- a pump that pumps waste into the bioreactor;

- a bioreactor, where the fermentation process itself takes place (there is also a device for mixing compost);

- a warm circuit that will heat up the biomass;

- a container for fertilizers that leave the reactor through a special tube;

- a filter and a compressor that are connected to a second tube leading from the reactor to the storage;

- gas storage where methane will accumulate.

On an industrial scale, the produced methane additionally goes through several stages of purification, and the fertilizers are mineralized.

Advantages and disadvantages

As you can see, installations for the production of biogas are not widely used even with an adequate raw material base. This is largely due to the disadvantages of this method of producing gas.

As you can see, installations for the production of biogas are not widely used even with an adequate raw material base. This is largely due to the disadvantages of this method of producing gas.

The positive aspects include:

- autonomy;

- you can make it yourself;

- the issue of waste disposal is being resolved;

- obtaining high-quality fertilizers;

- production of environmentally friendly fuel;

- more stable than solar and wind energy.

That is, for a private economy, the production of biogas at home solves several problems at once. There is a source for heating housing and heating food, there is no need to spend money on waste disposal and no longer need to buy fertilizers. And with proper investment, you can even sell the surplus to your neighbors.

Nevertheless, the disadvantages are quite serious:

- long fermentation process (from 10 days);

- high cost of professional equipment (it will pay off within 10-12 years);

- for the constant receipt of fuel, you need to make several installations (for heating a house of 50 square meters, an installation of at least 5 cubic meters is required);

- the need for a large amount of material of plant or animal origin;

- the gas produced will not always be of acceptable quality (good fuel should contain at least 60% methane, and better 80%, which is not always possible to achieve at home).

It should be noted that in Germany, where renewables are increasingly preferred, serious money is being invested in biogas energy. More than 2,200 biogas plants are already operating in the country.

It should be noted that in Germany, where renewables are increasingly preferred, serious money is being invested in biogas energy. More than 2,200 biogas plants are already operating in the country.

How to do the installation yourself

So, if the positives outweigh the negative, you can start assembling a biogas plant for a private house with your own hands. To see if the device will bring real benefits, you can try with a small design.It will provide fuel, for example, a conventional gas stove in the kitchen. Since, the larger the installation, the more expensive it will cost.

So, if the positives outweigh the negative, you can start assembling a biogas plant for a private house with your own hands. To see if the device will bring real benefits, you can try with a small design.It will provide fuel, for example, a conventional gas stove in the kitchen. Since, the larger the installation, the more expensive it will cost.

It is worth mentioning that one installation, due to the peculiarities of fermentation, cannot ensure the constant presence of gas. Therefore, many farmers make two and load them with biomaterial alternately.

You can extract biogas with your own hands using the following materials:

- two 100 liter barrels;

- PVC pipes of two diameters, for example, 20 and 40 mm, tees, corners;

- gas hoses;

- adapters from metal to plastic;

- two cameras from a truck;

- nipple adapters;

- shut-off valves;

- water filter;

- bucket with water;

The peculiarity of such a system is that over time, barrels can be added as much as necessary. But for now, you can get by with one or two.

Self-assembly of the installation

So, the procedure is as follows:

- We take two barrels. They must be washed and dried well. Better yet, sterilize.

- Next, we solder the system from pipes of a smaller diameter, which we then screw onto the outlet of the barrel, as in the picture. It should include an adapter with a metal thread, a shut-off valve and an adapter for a gas hose. We do the same with the second barrel.

- Next, we take a triple adapter for a gas hose, connect two barrels and put a long hose to the filter, in which some of the carbon dioxide will dissolve.

- We let the pipes down from the filter, and then up with the transition to a larger diameter. At the lowest point, we make an outlet pipe with shut-off valves. This system will remove hydrogen sulfide and condensate.

- From a pipe with a larger diameter, we again put the adapter on a smaller one and start up the line, from where three hoses will go.

- For the first hose, we solder a tee and an adapter for a gas hose. This hose must be connected to gas appliances such as a stove.

- Since the stove will not be constantly burning, it is necessary to provide a storage for the generated gas. The cameras act as this storage. They can be replaced with any plastic container, but for the first time they are enough. Just like with a hose for a stove, a tee is soldered under each chamber (for the latter, only a corner, or a tee with a plug is needed) and an adapter for the hose.

- An adapter is put on the hose, as on a conventional pump, and connected to the nipples.

Everything, the construction is assembled. All that remains is to fill the barrels with condensate and wait two weeks for the bacteria to start producing methane.

Several recommendations

Another important thing. The photo shows how the hose from the third barrel is in the water. The fact is that the first week since compost only carbon dioxide will be released. It is not needed in the system, so it will go out into the water. By the way, some farmers let carbon dioxide into greenhouses for better plant growth.

Another important thing. The photo shows how the hose from the third barrel is in the water. The fact is that the first week since compost only carbon dioxide will be released. It is not needed in the system, so it will go out into the water. By the way, some farmers let carbon dioxide into greenhouses for better plant growth.

To understand that it is time to connect the barrel to the system, you need to pull out the hose and bring a lighter to it. Don't worry. Since the biogas is not under high pressure, no explosion will occur. In addition, the final product will still contain up to 50% carbon dioxide, which does not burn. If a flame begins to protrude from the lighter from the tube, it means that biogas has already begun to be produced and you can connect.

The barrels themselves are best filled only to 70% of their volume. The fermentation process needs a space in which volatile compounds will form and elementarily bubble and gurgle.

One more nuance. Biogas is generated faster from livestock products. Accordingly, the hose in water can be checked after a week. If biogas is produced from plant products, the process of methane production may take a month.