Agidel pump, varieties, use on the farm

The usual rural backyard is gradually switching to equipment that spares physical strength, but at modest prices. The Agidel pump serves as an example of facilitating the work of the peasant, taking into account the specifics. The unpretentious unit withstands voltage drops in the network, is used to raise water from a level of up to 7 meters and to water the garden. Ufa Aggregate Software produces only 2 models of household appliances - Agidel-M and Agidel-10.

The usual rural backyard is gradually switching to equipment that spares physical strength, but at modest prices. The Agidel pump serves as an example of facilitating the work of the peasant, taking into account the specifics. The unpretentious unit withstands voltage drops in the network, is used to raise water from a level of up to 7 meters and to water the garden. Ufa Aggregate Software produces only 2 models of household appliances - Agidel-M and Agidel-10.

Features of surface installations Agidel

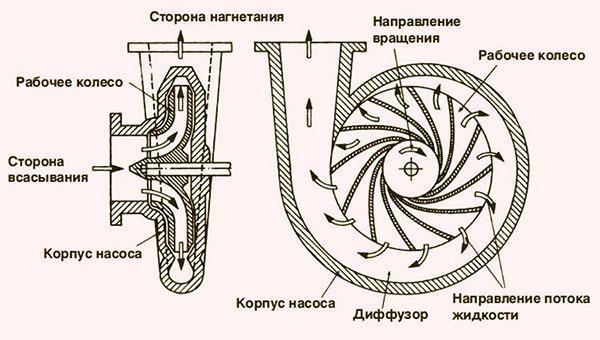

The pump consists of structural units:

- a casing bolted from the outside;

- engine housing;

- a snail that also serves as a body;

- impellers, on the same shaft with the engine armature;

- an electric motor, with a gasket and seals, for sealing against an aqueous medium.

The simple design of the device does not require additional protection, sealing of joints and therefore it is inexpensive, the tool is available to every user. Agidel pumps are protected from overheating, but they are used when pumping water below 400 C. The layout of products is different. Each of the pumps is installed on a solid foundation with level reference. It should be borne in mind that every 4 meters of a horizontal pipe is equal to the loss of the possibility of lifting from a depth of 1 m. The pump is installed in close proximity to the well.

Pump device Agidel-M

The device is mounted vertically on a rigid base. Water supply from a well and pumping over a distance of up to 35 meters is possible with a small 0.37 kW motor. If the well is up to 20 meters deep, an ejector is used, an external working element. The pump motor remains on the surface.

The device is mounted vertically on a rigid base. Water supply from a well and pumping over a distance of up to 35 meters is possible with a small 0.37 kW motor. If the well is up to 20 meters deep, an ejector is used, an external working element. The pump motor remains on the surface.

Agidel pump technical characteristics:

- lifting height - 7 m;

- productivity - 2, 9 cubic meters m / hour;

- diameter - 23.8 cm;

- length - 25.4 cm;

- weight - 6 kg;

- price - 4600 rubles.

Feature pump is the preliminary filling of the suction, including the working chamber. The device works only at a positive temperature or in a warmed room. A light water pump Agidel is used to raise water, placing it in a deep pit or equipping a raft that holds the pump on the surface of the mirror of the well from which water is taken. Only the Agidel-10 pump can be sent to sail, which does not require refilling of water at start-up.

In accordance with the operating instructions, the Agidel pump must pump an agent with a temperature below 400 C. Under these conditions, the engine runs without overheating. Before starting the device, water is poured, running "dry" will lead to inevitable breakdown. The pump must be protected from moisture and debris, from freezing temperatures.

It is imperative to use the pump ground loop, reliable insulation of all wire connections.

It is imperative to use the pump ground loop, reliable insulation of all wire connections.

The pump is equipped with a 1.5 m cable.For convenience, you can use an extension cord, or you can immediately replace the power cord of the device with another, longer one. This does not contradict the requirements of the operating instructions.

Compared to the Agidel M pump, the later modification, Agidel-10, has a horizontal layout and is 2 times more powerful. This device does not need to be primed before starting, it provides self-suction. The pump weighs 9 kg, the head is 30 m, and provides horizontal pumping of 50 meters. Productivity of 3.3 cubic meters / hour is sufficient for domestic needs.

Pump Difficulty and Maintenance

The reasons why the pump pumps poorly do not always depend on the device. The intake hose must be reinforced, do not change the section. When using a soft water line, the vacuum in the system forces the profile to contract under the influence of atmospheric pressure. The stuck hose keeps water out. To avoid problems, a reinforced hose or rubber hose with a wall thickness of more than 4 mm and an inner diameter of 25-30 mm is connected to the suction connection.

The reasons why the pump pumps poorly do not always depend on the device. The intake hose must be reinforced, do not change the section. When using a soft water line, the vacuum in the system forces the profile to contract under the influence of atmospheric pressure. The stuck hose keeps water out. To avoid problems, a reinforced hose or rubber hose with a wall thickness of more than 4 mm and an inner diameter of 25-30 mm is connected to the suction connection.

If water leaks from the drain hole, it is necessary to replace the oil seals on the motor shaft.

In order to get the oil seals, you need to free the impeller, remove it from the anchor. Inside the bushings there are 2 glands through the baffle. They are changed carefully, the partition is restored. Assemble the pump in reverse order.

Maintenance consists of periodically disassembling the apparatus, cleaning the impeller and lubricating the rotating parts. Usually such operations precede winter storage. Measures to prolong the life of the pump include installing a quality check valve on the supply line. All connections must be tight to prevent air leaks.

Do not use a power cable with multiple twists. A defective hose can cause a short circuit.

Advantages and disadvantages of pumps

The manufacturer has determined the pump life of 5 years. It is after this period that the first replacement of the oil seals will be required with the correct operation of the device. Do not use devices for pumping dirty water, the impeller can get abrasive wear, and the device will lose pressure.

The manufacturer has determined the pump life of 5 years. It is after this period that the first replacement of the oil seals will be required with the correct operation of the device. Do not use devices for pumping dirty water, the impeller can get abrasive wear, and the device will lose pressure.

The advantages of Agidel pumps include:

- easy maintenance and repair;

- low price of products;

- low consumption of electrical energy;

- long service life and adaptability to unstable voltage in the network.

The inconvenience is associated with the technical capabilities of the pump. He cannot take water from the depths. The need to install the device in close proximity to the sampling point.

Please note that a product in a plastic case is a counterfeit.

Hello, please tell me about the pump Agidel VTsN-1 1982. I inherited the pump from my father, three years ago it was used in good condition, this year I began to suck in air - I disassembled knocked out the oil seals - I didn’t notice where they were with a spring - tell me how to properly install the oil seals on this pump - is there a washer between the oil seals? Thanks in advance.

the springs of the oil seals towards the impeller, between the oil seals there is a plastic piece that should not block the drain hole!

if water starts to drip from the drain hole, it's time to change the oil seals! if the drain hole is blocked or ignore the water, the water will go into the electric motor