Can I repair petrol cutters myself?

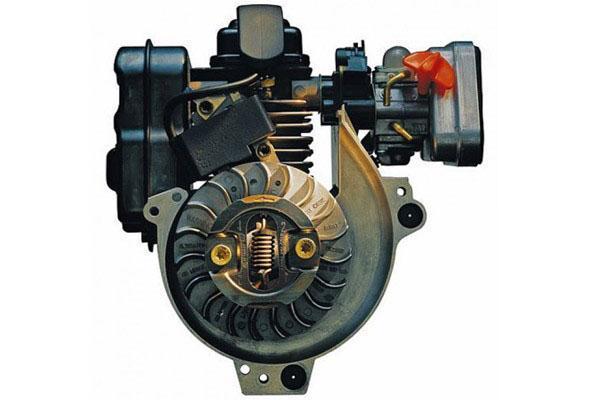

At first glance, a simple device for mowing grass with a two-stroke engine is fine-tuned. Repair of petrol cutters must be entrusted to a specialist or to study the technique yourself, using the operating instructions. The streamer maintenance is essential. Gearbox lubrication, line replacement, and teeth sharpening can be done on our own.

At first glance, a simple device for mowing grass with a two-stroke engine is fine-tuned. Repair of petrol cutters must be entrusted to a specialist or to study the technique yourself, using the operating instructions. The streamer maintenance is essential. Gearbox lubrication, line replacement, and teeth sharpening can be done on our own.

Gas mowers malfunctions and how to fix them

When choosing a petrol cutter, a device with a two-stroke engine is preferable, rather than a four-stroke one. The two-stroke motor is more maneuverable and easier to repair. With a four-stroke unit, the vibration level is lower.

They follow this, repair of petrol cutters is to troubleshoot;

- the engine does not start;

- the cutting mechanism is not picking up speed;

- the engine stalls;

- the reducer is heated;

- extraneous knock is heard, strong vibration of the bar.

Before eliminating the malfunction, you need to diagnose, determine the non-working unit.

It is important to know the lubrication points of the tool. Constant care, cleaning the device after work will extend its life. Before work, it is necessary to tighten the fastening bolts, prepare the fuel and fill the tank.

Chainsaw engine won't start

If the mechanism does not start, immediately stalls, check sequentially:

If the mechanism does not start, immediately stalls, check sequentially:

- is there fuel in the tank;

- serviceability of the spark plug;

- cleanliness of the air and fuel filter;

- the cleanliness of the breather and exhaust port.

It is necessary to fill it with a freshly prepared mixture based on AI-92, the oil is injected for accurate dosage with a medical syringe. This will help you avoid expensive chainsaw repairs.

It is necessary to make sure that the candle is working, it gives a spark when it comes into contact with the body. In this case, it is necessary to dry the candle channel, clean and dry the part itself. You can change the candle, but the canal still needs to be dried for 40 minutes. Check the health of the high-voltage wire, there may not always be a contact. A malfunction in the ignition unit when repairing a petrol cutter cannot be eliminated with your own hands.

If, when the air filter is removed, the engine does not stall, the reason is in it - it needs replacement or cleaning. Replacing the fuel filter is done with great care. Then check the cleanliness of the breather, remove the muffler mesh and clean the exhaust channel.

The next step will be carburetor repairwhere you have to find the problem and fix it, taking into account the tiny dimensions of the parts. If the simplest operations have not yielded results, in order not to disrupt the fine tuning of the system, it is better to entrust the repair to a specialist. Where to start diagnostics and how to properly repair petrol cutters with your own hands, check out the video:

The next step will be carburetor repairwhere you have to find the problem and fix it, taking into account the tiny dimensions of the parts. If the simplest operations have not yielded results, in order not to disrupt the fine tuning of the system, it is better to entrust the repair to a specialist. Where to start diagnostics and how to properly repair petrol cutters with your own hands, check out the video:

Repair and lubrication of the gas cutter

The role of the reducer is to transfer the torque from the motor shaft to the cutting tool through 2 toothed gears with different numbers of teeth. Torque is transmitted at an angle of 300... The number of revolutions of the lower cutting disc is 1.4 times less than the engine speed. Gears must be clean and lubricated. To supply oil to the teeth, there is a hole under the screw on top.

The role of the reducer is to transfer the torque from the motor shaft to the cutting tool through 2 toothed gears with different numbers of teeth. Torque is transmitted at an angle of 300... The number of revolutions of the lower cutting disc is 1.4 times less than the engine speed. Gears must be clean and lubricated. To supply oil to the teeth, there is a hole under the screw on top.

Lubrication of the petrol cutter gearbox is performed at least once a season. If the work is intense or there is abnormal noise in the lower unit, it is necessary to lubricate more often.

First, the place where the plug closes the hole should be cleared of soil and grass. Unscrew the plug with a suitable tool, it is included with the saw. We use a grease tube. Either a native lubricant from the manufacturer is selected, or well-known high-quality compounds such as Oleo-Mas, Litol-24, Azmol 158. We open the protective layer of the tube and lay the instrument on its side. Slowly rotating the knife, squeeze the grease into the gear housing. The gears, turning, carry the composition with teeth over the entire surface. You can also pour grease with a special syringe.

Insufficient or too much lubrication can cause the gear unit to heat up. An audible knock and backlash indicate a broken bearing or dirt due to a damaged boot. Bearings must be replaced using a puller, without using the heating method.

If the gearbox staggers and runs on the rod, it is necessary to replace the housing, or temporarily tighten the knot with a clamp to secure it to the pipe. If the knife stops rotating, it means that the gears do not engage - the teeth are worn out or crumbled. A pair will need to be replaced with a complete disassembly of the assembly.

If the gearbox staggers and runs on the rod, it is necessary to replace the housing, or temporarily tighten the knot with a clamp to secure it to the pipe. If the knife stops rotating, it means that the gears do not engage - the teeth are worn out or crumbled. A pair will need to be replaced with a complete disassembly of the assembly.

Disassembly of the gearbox with disassembly of the shaft and bearing assemblies must not be carried out by heating. When heated, the metal loses its strength properties and in the future the knot becomes unreliable. A puller is used to remove the bearings.

When replacing the gearbox, it is necessary to select a new unit, guided by:

- pipe diameter;

- the diameter of the drive shaft;

- section of the drive shaft;

- method of fastening protection

Caring for the cutting units of petrol cutters

The saw headset dulls or wears out over time. Working with the tool becomes tense, the load increases, and the swath quality deteriorates. Metal saw blades are sharpened, plastic ones are changed.

The saw headset dulls or wears out over time. Working with the tool becomes tense, the load increases, and the swath quality deteriorates. Metal saw blades are sharpened, plastic ones are changed.

If a line is used as a cutting tool, it gradually wears out, and new material is installed in the spool. The principle of operation of the line cutter is to gradually unwind the coil under the influence of centrifugal force. On contact with the grass, the fishing line is abraded; it is fed from the reel gradually. A special winding is needed so that two cutting elements come out at the same time and do not get confused with each other.

The figure shows how to properly wind the line onto the reel. petrol cutters... Before winding a new line, you must:

The figure shows how to properly wind the line onto the reel. petrol cutters... Before winding a new line, you must:

- unscrewing the nozzle, carefully remove the cover, holding the spring with your hand;

- remove scraps of old fishing line from the reel;

- measure 5 meters of a new string and fold it in half;

- in the coil, guides for 2 ends, hook the middle part into the recess and wind in the direction of the arrows for each half of the string;

- lead the remaining 20 cm through the special notches at the opposite ends of the coil;

- install the spring and washers, bring the ends of the line out, close the drum with a lid.

In order to better understand how to change the line on a petrol cutter, watch the video.