We build a practical shed for a summer residence on our own with minimal financial investment

A barn for a summer residence is not a luxury, but a necessity. It will store gardening tools, the remains of building materials and other things that have no place in a residential building. Of course, it is easier and faster to entrust the construction of an outbuilding to professional builders. But this service will cost a lot. For those who do not plan to spend an impressive amount, it is better to carry out the work on their own. Following the advice of experts, it will not be difficult to do this.

A barn for a summer residence is not a luxury, but a necessity. It will store gardening tools, the remains of building materials and other things that have no place in a residential building. Of course, it is easier and faster to entrust the construction of an outbuilding to professional builders. But this service will cost a lot. For those who do not plan to spend an impressive amount, it is better to carry out the work on their own. Following the advice of experts, it will not be difficult to do this.

Choosing the right place

If the barn is intended for keeping animals, then it must be located at a distance of at least 12 meters from fence.

For the construction of a barn in the country, places are often chosen where it is impractical to have a garden or other buildings. In this case, the passage to the structure must be free. This is the only way to easily remove a wheelbarrow and other large items into the utility block.

For the building, a place is chosen on an elevation. If you place it in a lowland, then in the spring it will be flooded with melt water. To protect against strong winds, the shed is placed on the windward side of the site.

Dimensions

To calculate the required amount of building materials, you need to know the size of the future barn. The parameters of the structure depend on what is planned to be stored in it.

To calculate the required amount of building materials, you need to know the size of the future barn. The parameters of the structure depend on what is planned to be stored in it.

Experts give the following recommendations:

- To store garden tools, you will need about 2.5 square meters of area.

- If there is a wheelbarrow in the barn, a pump and other large-sized equipment will need 6 square meters.

- For paints and varnishes, tools, you need 3 square meters.

On average, an area of 5 to 15 square meters is allocated for a barn. If the building will be used for breeding livestock or poultry, then its dimensions are selected based on the number and characteristics of animals.

On average, an area of 5 to 15 square meters is allocated for a barn. If the building will be used for breeding livestock or poultry, then its dimensions are selected based on the number and characteristics of animals.

Do I need a foundation for a barn for a summer residence

The need to build a foundation depends on the type of building. A light shed of a small area can be placed directly on the ground. For example, ready-made prefabricated plastic buildings are sold in modern stores. They do not need to prepare the base. If it is decided to build a utility block from strong durable materials, then arranging the foundation is a necessary procedure.

The need to build a foundation depends on the type of building. A light shed of a small area can be placed directly on the ground. For example, ready-made prefabricated plastic buildings are sold in modern stores. They do not need to prepare the base. If it is decided to build a utility block from strong durable materials, then arranging the foundation is a necessary procedure.

There are several types of foundations for buildings:

- Tape. It is a monolithic concrete tape. For the construction of a barn, its unburied type is suitable. Such a foundation is laid into the soil to a depth of no more than 20 cm. Suitable for buildings made of bricks or foam blocks.

- Blocky. Such a base is suitable for light structures, for example, made of wood. Blocks are used for its arrangement. They are placed with a step of about a meter from each other on a previously prepared sand cushion.

- Columnar.Ideal for frame buildings. The posts are made of bricks or concrete.

- Pile. Piles are driven into the ground, on which the grillage is subsequently mounted. Such foundation can be installed on any type of ground. Its significant disadvantage is its high price.

Most often, for small outbuildings, a columnar or block foundation is chosen. They are easy to build with your own hands. The finished building will be strong and durable.

Wooden shed for summer cottages

Wood is the most readily available and environmentally friendly material. Structures are erected from it using frame technology. First, a crate is built from a thick bar. After that, it is sheathed with boards or wood boards. Step-by-step instructions will help you quickly build a wooden shed for a summer residence with your own hands.

Step one: building the foundation

After the drawings of the future utility block are drawn up and all the necessary materials are purchased, you can proceed to construction. They start with the construction of the base. Since wood is a light material, a columnar, unburied foundation is suitable. For it, cinder blocks with a size of 600x300x200 are used.

After the drawings of the future utility block are drawn up and all the necessary materials are purchased, you can proceed to construction. They start with the construction of the base. Since wood is a light material, a columnar, unburied foundation is suitable. For it, cinder blocks with a size of 600x300x200 are used.

When arranging the base, adhere to the following sequence of actions:

- In the locations of the support points, a soil layer is removed 20-25 cm deep.

- A cushion of gravel and sand is being prepared. The backfill is compacted tightly. To do this, it is recommended to spill it with water first.

- Pillars are laid out. The blocks are fixed with concrete.

- After the final drying of the solution, a layer of waterproofing material, for example, roofing material, is laid on each pillar.

- A grillage from a bar with a section of 150x150 mm is mounted. The bars are connected in bunches in half a tree. You can join them end-to-end, but then you have to apply a mounting plate.

The timber used for the construction of the grillage is pretreated with the composition of fire-retardant protection. It will protect against mold and mildew, prolong the durability of the product and increase its fire safety.

Step two: creating the floor

Planks 150x60 mm, installed on the edge, are attached to the finished grillage. To fix them, metal staples of the required size are used. These will be the lags of the future floor. They are aligned so that their top edge is flush with the grillage surface.

Planks 150x60 mm, installed on the edge, are attached to the finished grillage. To fix them, metal staples of the required size are used. These will be the lags of the future floor. They are aligned so that their top edge is flush with the grillage surface.

Sheet material is laid on top of the logs. Better to use 15 mm plywood. In order to save money, OSB sheets are also used, but they will turn out to be less durable. You can make a floor from 20 mm thick planed boards. But such material is more expensive, and the work will be more labor-intensive.

Sheet material is laid on top of the logs. Better to use 15 mm plywood. In order to save money, OSB sheets are also used, but they will turn out to be less durable. You can make a floor from 20 mm thick planed boards. But such material is more expensive, and the work will be more labor-intensive.

Step three: assembling the wall and roof frame

The frame of the structure is knocked down. In the corners, racks of 15x15 cm timber are installed. For the rest of the racks, a board of 100x50 mm is used. The distance between the supports is 60 cm. The lower and upper strapping is in progress.

The frame of the structure is knocked down. In the corners, racks of 15x15 cm timber are installed. For the rest of the racks, a board of 100x50 mm is used. The distance between the supports is 60 cm. The lower and upper strapping is in progress.

To organize window and door openings, boards are nailed in the horizontal direction. They are stiffened by installing an additional rack in the middle of the future window or door.

A shed roof truss system is being assembled. The step between the rafters is 60 mm. They are made of the same boards as the rest of the frame. They are placed on the edge. The overhang of the roof should be 30 cm on both sides.

Step four: final roof assembly

For lathing, boards of 100x25 mm are used. They are laid out in 40 cm increments. Attachment to the rafters is carried out using nails.

For lathing, boards of 100x25 mm are used. They are laid out in 40 cm increments. Attachment to the rafters is carried out using nails.

A layer of waterproofing material is laid on top of the finished lathing. Then you can proceed to the flooring of the topcoat. Slate, profiled sheet, soft tiles or any other roofing material are used.

Step five: wall cladding

For this, a board or any sheet material is used. The most economical option is OSB 9.5 mm thick. The sheets are attached to the frame with screws or nails.

For this, a board or any sheet material is used. The most economical option is OSB 9.5 mm thick. The sheets are attached to the frame with screws or nails.

The final stage is the installation of windows and doors.After that, the shed can be painted, sheathed with clapboard or siding. So it will become not only practical, but also beautiful.

The barn can be made warm. For this, insulation is laid in the gaps between the racks. It is better to use mineral wool mats. From above, the insulation is sheathed with sheet material.

Shed from corrugated board

You can build a small shed in the country with your own hands from corrugated board and profiled pipes. This material is relatively inexpensive and easy to work with. The finished structure will be lightweight. If necessary, it can be made mobile. Arrangement of the foundation under such a structure is not necessary.

You can build a small shed in the country with your own hands from corrugated board and profiled pipes. This material is relatively inexpensive and easy to work with. The finished structure will be lightweight. If necessary, it can be made mobile. Arrangement of the foundation under such a structure is not necessary.

The frame of the building is created from a profiled pipe. Parts are joined together by welding. Thanks to this, the structure is durable and reliable. From such material, you can create a shed of any size and configuration.

The finished frame is sheathed with corrugated board. The sheets are attached to the base with special self-tapping screws with a rubberized washer. Pieces of any size and shape can be cut from corrugated board. For this, a jigsaw with a metal attachment, special scissors or a circular saw is used.

It is not recommended to cut the profiled sheet with a grinder. When rotating, the cut-off wheel heats up the metal very much. This leads to melting of the polymer coating applied to it. As a result, corrosion will occur faster in the cut zone and the corrugated board will not last long.

The disadvantages of a shed made of corrugated board include the complexity of installation. Working with metal requires certain skills. It is much easier for beginners who are just learning the basics of construction to work with a tree.

A significant drawback of metal buildings is their high thermal conductivity. In the summer months, such a building will be very hot, and in the winter it will freeze. Even in the presence of a layer of insulation, the posts and profiled pipes will intensively give off heat.

Brick shed

For those who want to build a fundamental durable structure, brick is the ideal material. Such a structure, subject to the construction rules, will stand for several decades. He is not afraid of frost, heat, strong wind and other weather disasters.

For those who want to build a fundamental durable structure, brick is the ideal material. Such a structure, subject to the construction rules, will stand for several decades. He is not afraid of frost, heat, strong wind and other weather disasters.

However, the brick shed has many disadvantages:

- High price. More often it turns out to be unjustified. The only exceptions are situations when the building will be used for breeding large animals. In this case, the structure must be reliable.

- The need to build a solid foundation. Brick is a heavy material. Therefore, it is recommended to build a strip base under it.

- High thermal conductivity. To keep the warmth indoors during the winter months, the walls will have to be thick enough. The width of the masonry should be more than 80 cm. And this requires not only impressive financial costs, but also a large free area for construction.

Many experts agree that brick is not the best choice for outbuildings. You can find a cheaper, but equally durable alternative to it.

Household building made of foam block

The foam block is one of the most popular building materials today. It is quite lightweight and durable. You can build a shed out of it yourself without involving heavy equipment.

The foam block is one of the most popular building materials today. It is quite lightweight and durable. You can build a shed out of it yourself without involving heavy equipment.

The following advantages of buildings made of this material are distinguished:

- Average price. If you compare it with a tree or profiled sheet, then a foam block shed will cost more. And in comparison with brick, construction will be cheap. At the same time, the foam block is not inferior to brick in terms of reliability and durability and is significantly superior to wood.

- Ease of installation. The block structure is easy to assemble like a constructor. The elements are fastened to each other using cement mortar.

- Low weight. The foam blocks are easy to transport. You can work with them alone.

- Average thermal conductivity.A single block wall is sufficient to keep the heat in the room. Therefore, such a shed does not require additional insulation.

- No processing needed. Foam blocks are not damaged by parasites, do not burn, and mold does not develop on them. Therefore, they do not need to be further processed before construction.

The disadvantages of a foam block shed include the need to build a solid foundation. It is best to pour a monolithic tape base of concrete. Columnar and pile foundations will not work in this case.

Another disadvantage of foam block sheds is their shrinkage. The material slowly gains strength, and therefore, over time, cracks may appear on the walls.

Aerated block shed

The gas block is similar in properties to the foam block. Both materials are lightweight, fireproof, frost-resistant, and have low thermal conductivity. The gas block differs in manufacturing technology, strength characteristics and moisture absorption capacity.

The gas block is similar in properties to the foam block. Both materials are lightweight, fireproof, frost-resistant, and have low thermal conductivity. The gas block differs in manufacturing technology, strength characteristics and moisture absorption capacity.

Aluminum powder is used in the production of the gas block. Due to chemical reactions that occur when it comes into contact with other components, gas bubbles are formed. They are distributed evenly throughout the block. As a result, the material resembles a sponge. It absorbs moisture easily. This leads to a decrease in thermal insulation properties. Therefore, structures made of gas blocks often have cracks along the walls.

A shed for a summer residence made of such material has the same advantages as a foam concrete building. The disadvantage is the need to finish it. Moreover, you need to choose a material that would reliably protect the walls from moisture. In addition, aerated concrete can withstand no more than 25 freezing and thawing cycles. Consequently, the service life of such a building will be no more than 25 years.

It is difficult to carry out high-quality finishing work on the walls made of aerated concrete. Walls do not hold plaster mixes well. Several coats are required. It is difficult to install fasteners in such walls. To organize hanging shelves in the barn, you will have to use special devices.

Ready solutions

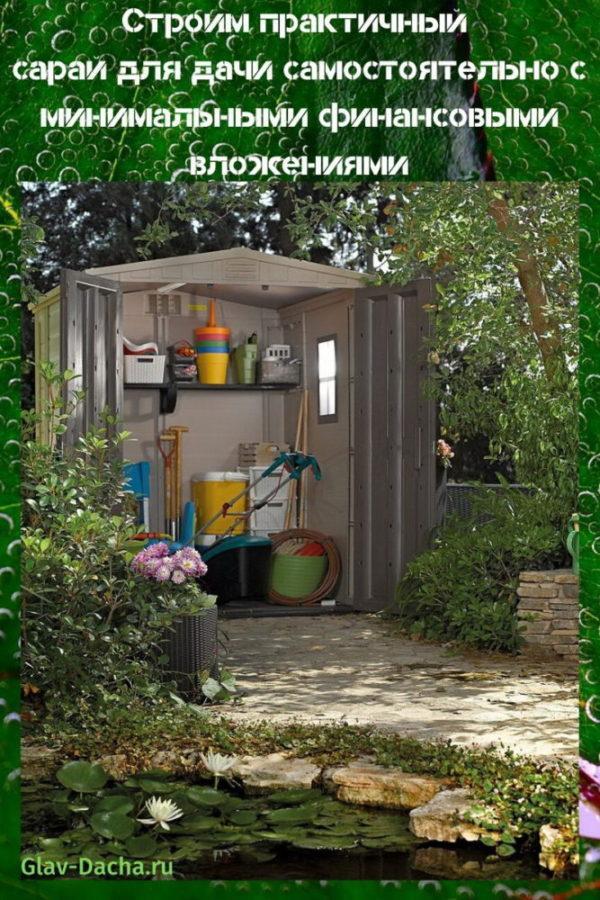

The simplest answer to the question of how to build a shed in the country with your own hands is the acquisition of a prefabricated plastic structure. Today these buildings are sold in many specialized stores. This is a collection of individual parts. It comes with detailed installation instructions.

The simplest answer to the question of how to build a shed in the country with your own hands is the acquisition of a prefabricated plastic structure. Today these buildings are sold in many specialized stores. This is a collection of individual parts. It comes with detailed installation instructions.

First, the frame of such a shed is assembled. There is no need to build a foundation, since the structure is very light. Wall and roof elements are attached to the finished frame. Models are on sale, both with and without floor.

The plastic prefabricated shed for the summer cottage does not have a heater. Because of this, walls can crack in severe frosts. Therefore, such designs are considered short-lived. They must never be used for keeping animals.

There are also container-type ready-made solutions. They represent a metal frame sheathed with metal sheets. Outwardly, it resembles a shipping container. Such models are more often produced with insulation. They are suitable for organizing a pantry, summer shower or toilet. There is an opportunity for communications.

Container buildings are installed on the foundation. It is recommended to erect a columnar base or pour a monolithic slab of concrete. Only in this way will the dacha shed last a long time. An additional advantage of such sheds is their mobility. They can be easily moved to a new location if necessary. The main disadvantage is the high price.

The choice of material for arranging the roof

Summer residents often store not only buckets and shovels in the barn, but also expensive power tools, for example, lawn mowers, cultivators and others. Therefore, it is important that the roof of the building reliably protects the room from rain and snow getting inside.

There are several options:

- Slate - inexpensive, strong enough, durable.It can be used repeatedly. For many, slate remains after replacing the roof on a residential building. It is quite suitable for a barn. The main disadvantages of such a material are its fragility and impressive weight. It is important to prepare a solid crate under the cover.

- Metal tiles. Differs in lightness, durability and reliability. Today, sheets are produced with various profile shapes. Therefore, the barn can be turned into a full-fledged element of landscape design.

- Professional sheet. It is similar to metal tiles both in appearance and in characteristics. It is made of thinner metal, and therefore has less strength and durability. But it wins significantly on the price.

- Ondulin. These are sheets of bitumen-fibrous material. Their main advantages are durability and ease of installation. The material does not fade in the sun, reliably protects the structure from precipitation, is lightweight, and looks attractive. In order for the roof to be strong, it is important to install it correctly. At least 20 nails are used to fix one sheet. The main disadvantage of ondulin is considered to be its flammability. The material is highly flammable and sustains combustion.

- Roofing material. This material is considered obsolete today, but it is still used. It is a cardboard impregnated with bituminous mastics and covered with refractory bitumen on the outside. Available in rolls. It's cheap, easy to fit. To create a reliable coating, roofing material is laid in several layers. Canvases are glued with a gas burner.

The best option for a barn is slate or profiled sheet. The latter is more popular today. The sheets are light, and therefore the laying can be done alone.

Build a shed for a summer residence with your own hands is a simple task. The main thing is to plan everything in advance, draw up a drawing. It is recommended to purchase materials with a margin of 10-15%. Even a novice master, observing all the recommendations of specialists, will cope with the work in a few days.