Two options for making a wood lathe with your own hands

The most difficult thing for those who like to craft from wood is to give the workpiece a round shape. A wood lathe will help with this. With its help, beautiful door handles, openwork balusters, original dishes and souvenirs, children's toys, carved furniture, and many elements for interior decor are easily and quickly grinded. In a word, one such machine can turn a house into a fairytale tower. The lathe for wood is so simple that anyone who knows how to work with a drill can do it with their own hands. Read the article: Wood carving lessons!

The most difficult thing for those who like to craft from wood is to give the workpiece a round shape. A wood lathe will help with this. With its help, beautiful door handles, openwork balusters, original dishes and souvenirs, children's toys, carved furniture, and many elements for interior decor are easily and quickly grinded. In a word, one such machine can turn a house into a fairytale tower. The lathe for wood is so simple that anyone who knows how to work with a drill can do it with their own hands. Read the article: Wood carving lessons!

Types of lathes and their capabilities

Also, the machines differ in functionality. The following varieties are distinguished:

- Turning-copying allows you to create several identical parts. To operate a lathe with a copier, a stencil is required, according to which an exact copy is created.

- Turning-milling has additional possibilities for groove boring.

- The screw-lathe is able to cut threads and sharpen products under the cone.

- Lobotokarny is used for the manufacture of objects on a wide flat base - bas-reliefs, high-reliefs, volumetric paintings.

- The round-rod gives any workpiece a round shape in cross-section. It is widely used for the production of hatchets, cuttings for gardening tools, handles for hand tools - chisels, knives, mops. The workpiece itself is stationary in a circular-rod lathe, only wood cutters rotate.

According to the degree of automation, they are divided into manual, semi-automatic and CNC machines, in which the turner only sets the workpiece and turns on the specified program.

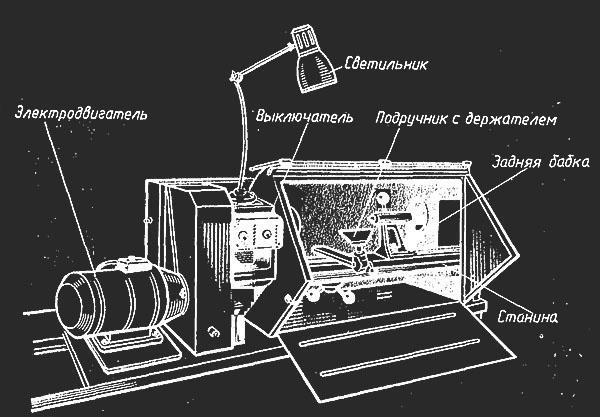

Lathe device

A typical wood lathe consists of several main parts: an electric motor, a bed, a handguard, and a headstock and tailstock.

A typical wood lathe consists of several main parts: an electric motor, a bed, a handguard, and a headstock and tailstock.

The bed is the basis of the machine, all other mechanisms are fixed on it. As a rule, it is solid cast iron. The large weight of the monolithic bed can significantly reduce the vibration of the equipment, which negatively affects the service life of the machine.

The headstock has several functions. The workpiece is attached to it and rotation is transmitted from the electric motor through the spindle installed on it using a belt drive.

The speed of rotation of the part is changed by moving the belt onto pulleys of the required diameter. This arrangement is similar to how the gears work on a modern multi-speed bicycle.

The workpiece in the spindle is held at one end by a drive chuck, and at the other end by a lathe chuck for wood on the tailstock.

The functionality of a wood lathe can be expanded with a faceplate. A part is attached to it if you need to grind its ends, which were clamped by cartridges.

Also, machines are equipped with copiers, which allow you to make several identical parts with great accuracy.

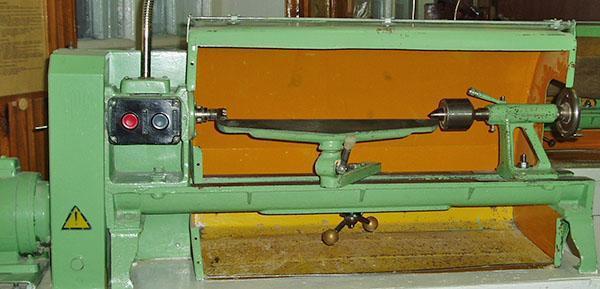

Brief description and characteristics of the lathe STD 120M

The machine has a simple and reliable design, proven over the years.It is installed in school workshops, vocational schools, in the shops of enterprises, and is used at home. With its help, the following wood turning work is performed:

The machine has a simple and reliable design, proven over the years.It is installed in school workshops, vocational schools, in the shops of enterprises, and is used at home. With its help, the following wood turning work is performed:

- drilling;

- stencil turning;

- sharpening of rotating parts of different profiles;

- facing, rounding and cutting off parts at different angles;

- processing of flat surfaces using a faceplate.

The machine device has its own characteristics:

- the change in rotation speed is changed by moving the belt to pulleys of different diameters;

- the control unit is located on the headstock for maximum convenience during work;

- the equipment set includes several spindle-type nozzles, which allows you to fix workpieces with any type of ends;

- for the safety of the worker, the machine is equipped with a casing and shutters with transparent windows;

- a cleaning unit is additionally connected to remove chips.

The unit is connected to a three-phase electrical network with a voltage of 380 V and compulsory grounding.

How to make the simplest lathe from a drill

As you can see, the device of this unit is very simple, and everyone can make a homemade lathe for wood. The most elementary tool for turning workpieces is obtained from a conventional drill. It will allow you to carry out simple turning work at home and save on the purchase of special equipment. The drill in this case replaces the headstock and rotation drive.

As you can see, the device of this unit is very simple, and everyone can make a homemade lathe for wood. The most elementary tool for turning workpieces is obtained from a conventional drill. It will allow you to carry out simple turning work at home and save on the purchase of special equipment. The drill in this case replaces the headstock and rotation drive.

Instead of a cast iron bed, a workbench is used. Wood stops are fixed on it for attaching a drill and a tailstock. The back stop is made of bars and an adjustable screw, the end of which is sharpened on a cone. Various drill bits, which are attached instead of a drill, serve as turning cutters for wood.

Instead of a cast iron bed, a workbench is used. Wood stops are fixed on it for attaching a drill and a tailstock. The back stop is made of bars and an adjustable screw, the end of which is sharpened on a cone. Various drill bits, which are attached instead of a drill, serve as turning cutters for wood.

On such a simple device, handles for tools and doors, simple decorative items, balusters and much more are grinded.

DIY wood lathe

This design is a little more complicated, but it also has more possibilities. At the heart of a homemade bed, welded from metal corners and installed on a workbench or on its legs. Special attention is paid to the reliability of the bed so that the machine vibrates as little as possible during operation. The design of the bed provides for the presence of a longitudinal guide for moving individual elements.

This design is a little more complicated, but it also has more possibilities. At the heart of a homemade bed, welded from metal corners and installed on a workbench or on its legs. Special attention is paid to the reliability of the bed so that the machine vibrates as little as possible during operation. The design of the bed provides for the presence of a longitudinal guide for moving individual elements.

The cutting tool rests on the handguard. The bracket for it must not only move in the horizontal plane, but also rotate along the axis of the attachment. The support plane of the handler must coincide with the axis of rotation of the part in processing.

Any serviceable electric motor of any household appliance with sufficient power can serve as a drive. The easiest way is to mount the spindle directly onto the shaft without transfer devices.

This method is cheaper and saves space on the bed. But it also has its drawbacks - it is impossible to control the rotation speed and uneven wear of bearings, which are not designed for longitudinal load.

Therefore, it is worth providing a separate unit for the spindle. The torque will be supplied by belt driven pulleys.

Therefore, it is worth providing a separate unit for the spindle. The torque will be supplied by belt driven pulleys.

A spindle is a part that fixes the workpiece by transmitting torque to it. May look like a slip-toothed stop or have screw clips. The version with clamps is called a faceplate.

A spindle is a part that fixes the workpiece by transmitting torque to it. May look like a slip-toothed stop or have screw clips. The version with clamps is called a faceplate.

The tailstock holds the workpiece on the axis of rotation. The easiest option is a tapered bolt. A more complex stop is made from a support bearing.

For normal operation of the machine, the centers of both headstock and the plane of the handguard should ideally coincide.

As a result, a homemade wood lathe should look something like this:

Particular attention should be paid to the stability of the entire structure so that strong lateral force does not overturn the machine. This can cause injury when the motor is running.To eliminate the most common failures when working with a homemade unit, consider the following subtleties:

Particular attention should be paid to the stability of the entire structure so that strong lateral force does not overturn the machine. This can cause injury when the motor is running.To eliminate the most common failures when working with a homemade unit, consider the following subtleties:

- the workpiece must rotate on the turner;

- before processing the workpiece with cutters, give it a cylindrical shape (if possible);

- the cutter should be pressed against the workpiece at an acute angle;

- final grinding is done with fine sandpaper, this operation is carried out with gloves so as not to burn your hands from friction;

- the harder the wood, the higher the shaft rotation speed should be.

When working on a wood lathe, do not forget about safety. The worker must use protective equipment - special glasses, gloves, and, if necessary, a respirator.

The possibilities of a home-made lathe are expanded by equipping with additional nozzles and fixtures - they apply paint to a rotating part, grind identical parts using a copier, and even wind up transformers.