DIY air pump

An air pump that can inflate a bicycle tire in 2 minutes cannot be found in a store, but you can make it yourself. They can create a tire pressure of up to 60 atmospheres. The secret to generating such high pressure and pumping is in the piston. In the open state, it passes pressure up to 10 atmospheres, and in the closed state it can hold pressure up to 60 atmospheres. A pressure over 100 atmospheres will rupture the tire, so there is no point in making a high-pressure air pump. Consider the manufacturing instructions pump medium pressure.

An air pump that can inflate a bicycle tire in 2 minutes cannot be found in a store, but you can make it yourself. They can create a tire pressure of up to 60 atmospheres. The secret to generating such high pressure and pumping is in the piston. In the open state, it passes pressure up to 10 atmospheres, and in the closed state it can hold pressure up to 60 atmospheres. A pressure over 100 atmospheres will rupture the tire, so there is no point in making a high-pressure air pump. Consider the manufacturing instructions pump medium pressure.

Parts for pump assembly

To assemble the medium pressure air pump housing you will need:

- board and handle from a shovel for the stand and pump handle;

- water outlet with a diameter of 16 mm and an internal thread of 0.5 mm;

- brake hose from a gazelle;

- rivet;

- cap on the nipple.

To assemble the cylinder:

- adapter for polypropylene pipe with a diameter of 20 mm. Outer thread of the adapter - 0.5 mm;

- polypropylene pipe for hot water with a diameter of 20 mm;

- pipe plug;

- aluminum tube - 12 mm;

- two nipples from a tubeless tire.

You will also need a scalpel, sandpaper, drill, epoxy glue, fitting.

Assembling the pump

Let's assemble the valve. The nipple needs to be shaped like a cone. To do this, clamp it in a drill and grind it off with sandpaper. Next, you need to grind the cone. The diameter of the thickest part must be 1 mm larger than the inner diameter of the 20th pipe. The cone must be inserted into the aluminum tube, after sanding one edge of the tube with sandpaper. Mark a point 1 cm above the piston position and drill a hole. Pour epoxy into the hole and lubricate the joint between the cone and the pipe. The pump piston is ready.

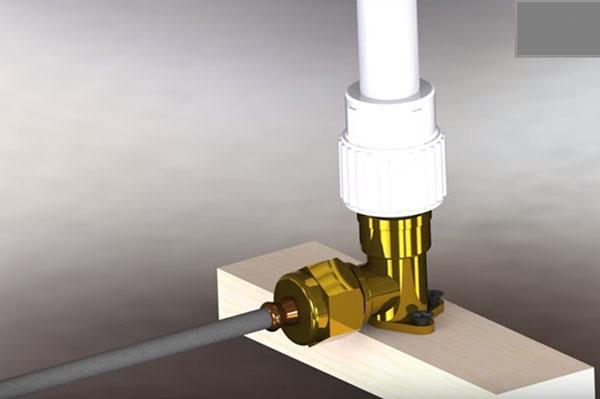

Next, let's assemble the cylinder. Insert a fitting into the 0.5 mm adapter, and fix the fitting itself in a drill. Next, turn on the drill and slide the adapter onto the 20 mm pipe using friction welding.

Cut the thickest part from the second nipple to the line. Then you need to insert it into the adapter and align it in the center. Fill the empty space with epoxy glue.

Let's go to the hose. Cut off one end. A male end is needed. Erase the thread with a file. At the water outlet, cut off the fitting directly under the rubber ring. Next, carefully re-drill the holes with a 9-9.5 mm drill. It is necessary that the ground thread can be freely screwed into the side hole. Fill the top hole of the water outlet with cold welding and make sure that the adapter can be screwed into it.

To assemble the cylinder, cut a piece of the polypropylene pipe so that it is a few centimeters shorter than the aluminum one. Then screw the bolt into the pipe plug. Use friction welding to slide the plug onto the pipe. Make a hole in it so that you can pass an aluminum tube through it. Next, assemble the pump with super glue and install the handle on the bolt with nuts.