The best solution for arranging a recreation area in the country at an affordable price is polycarbonate gazebos

Polycarbonate gazebos are the ideal solution for a modern summer cottage or private house. This material has a number of positive qualities, which include affordable pricing and durability. Polycarbonate structures are easy to install, lightweight, which simplifies transportation and installation with subsequent fastening to a metal frame.

Polycarbonate gazebos are the ideal solution for a modern summer cottage or private house. This material has a number of positive qualities, which include affordable pricing and durability. Polycarbonate structures are easy to install, lightweight, which simplifies transportation and installation with subsequent fastening to a metal frame.

Related article: polycarbonate fence in the country.

Pros of a polycarbonate gazebo

In addition to wood, they also create high-quality and durable gazebos made of silicate brickswhose cost is higher than a tree. Brick is valued for its long service life, but it creates a lot of difficulties in construction. Mixing the mortar requires at least one assistant, as well as the presence of such a tool as a concrete mixer. And the masonry process itself requires experience and skill. Therefore, a domed brick gazebo will not be an ideal example of site diversity for many.

Polycarbonate and polyvinyl chloride are the materials to look out for. Such environmentally friendly raw materials will last a long time, the affordable price makes it twice as popular. That is why, when installing arbors or a simple pergola with a polycarbonate roof, this type of plastic is used more often than expensive wood.

Polycarbonate and polyvinyl chloride are the materials to look out for. Such environmentally friendly raw materials will last a long time, the affordable price makes it twice as popular. That is why, when installing arbors or a simple pergola with a polycarbonate roof, this type of plastic is used more often than expensive wood.

Advantages of a polycarbonate gazebo:

- Low cost. This fact allows everyone to purchase material, and if they have the necessary skills, to mount the structure and coating on their own.

- Low weight. Very important, as lightweight structures do not require foundation pouring, resulting in lower costs.

- Immunity to sudden temperature changes. The gazebo is installed in the open air, so precipitation or changes in heat and cold can spoil the material, but not polycarbonate, which easily tolerates sharp drops from -40 C to +120 C.

- Convenience under technological influences. For example, polycarbonate is easy to cut, it does not crumble when drilling, such material can be easily fixed with ordinary construction brackets without any damage.

- High fire performance. Even after a mark of +125 C, the polycarbonate sheet will only begin to melt, but will not ignite.

Polycarbonate gazebos are very easy to clean - just wipe the surfaces with a damp cloth, and you can enjoy cleanliness.

What kind of material should be used when building a gazebo

Polycarbonate, as a material obtained from active chemical compounds, consists of several main types:

- Cellular. Externally, the material is presented as a panel consisting of plastic of varying degrees of shade (used as a transparent surface in combination with matte).Layers of polycarbonate pass from one to another, which is very similar in structure to a honeycomb. The honeycomb type of plastic has a high thermal insulation level, since air remains inside each layer, which gives a similar effect.

- Monolithic. It is the monolithic variety of polycarbonate that is used in the construction of arbors. It is made in the form of sheets of different areas, but with a solid structure. In the production of the material, the technology of hot forming is used, which makes it possible to obtain sheets not only of large sizes, but also with bending. Such curvature of the plane makes the design, for example, of a round gazebo, modern and stylish and will definitely not leave indifferent any guest.

Monolithic polycarbonate has the following properties:

- high resistance to mechanical damage: impacts, chips, cracks, abrasions;

- resistance to ultraviolet radiation;

- good transparency that does not change under the influence of temperature extremes.

Polycarbonate gazebos

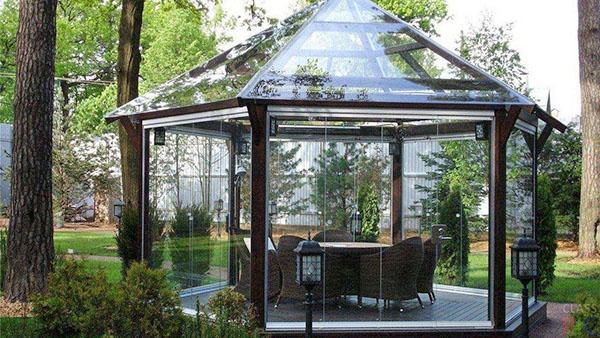

The appearance of the gazebo is very important, as it must be in harmony with the design of the site. Therefore, polycarbonate structures are of various shapes and sizes; they can also be mounted both open and closed.

The main types of structures:

- Dome. This gazebo will be the perfect addition to any garden. Dome structures are most often made of an open type, the roof is made in the form of a hemisphere. This shape attracts with its smooth curves, which also creates fewer problems in winter when it is necessary to remove snow.

- Round. A similar design differs from the rest by the smooth transition of the walls of the gazebo to the roof. The frame racks come out of the foundation and are connected at the top, at one point. The main advantage of such a gazebo is its high structural stability. Most often, round gazebos are made of a closed type, but for greater freshness, small windows are mounted on the walls.

- Rectangular. A standard design preferred by many site owners. It requires less installation time and fewer problems with material selection. The ideal building material for installing a rectangular gazebo is wood, but round or square metal pillars can also be used. The dimensions of this design are made large enough, especially for placement inside several recreation areas.

- Sliding. For this type, a rectangular design is usually chosen (it simplifies the installation of doors), but the doors are mounted of a sliding type, which allows you to quickly transfer the gazebo from open to closed type.

The sliding structure is the perfect combination of technology and modern design. Installation will require accurate calculations and measurements.

The sliding structure is the perfect combination of technology and modern design. Installation will require accurate calculations and measurements.

Stages of construction of a polycarbonate gazebo

If there is a desire to build a miracle plastic gazebo on your site, then you should roughly know the sequence of the process. It also does not hurt to have construction skills and the necessary tools. For speed of construction, you can invite a friend, because an extra pair of hands will never interfere with the installation process. It is important to remember that a polycarbonate gazebo built with your own hands (photo attached below) and with love will delight the owner for a very long period of time.

If there is a desire to build a miracle plastic gazebo on your site, then you should roughly know the sequence of the process. It also does not hurt to have construction skills and the necessary tools. For speed of construction, you can invite a friend, because an extra pair of hands will never interfere with the installation process. It is important to remember that a polycarbonate gazebo built with your own hands (photo attached below) and with love will delight the owner for a very long period of time.

Choosing a suitable location is the initial stage of any construction

All construction work should begin with the selection of a suitable location and correct markings. This procedure should be approached thoroughly, since the slightest inaccuracies can spoil the appearance of the future design.

All construction work should begin with the selection of a suitable location and correct markings. This procedure should be approached thoroughly, since the slightest inaccuracies can spoil the appearance of the future design.

You should not choose the most solid polycarbonate base for the gazebo - this material is very light, the structure will not sag even after several years.

The most ordinary soil will do, ideally it could be a small hill.If there are trees nearby, it will only give positive emotions during future gatherings, and in the summer - a refreshing coolness.

Pouring the foundation

Polycarbonate is a material that does not require the installation of a foundation, which cannot always be said about the soil on which the gazebo is installed. Soft soil will cause the structure to sink in the future, especially if the owners of the site want to build a gazebo of solid size.

Polycarbonate is a material that does not require the installation of a foundation, which cannot always be said about the soil on which the gazebo is installed. Soft soil will cause the structure to sink in the future, especially if the owners of the site want to build a gazebo of solid size.

For a gazebo with a polycarbonate roof, the most practical option would be to fill in load-bearing elements - metal pipes on which the entire structure rests. This reduces the consumption of building materials (sand, cement, screenings) and simplifies the work. Mounting such a foundation does not require the use of a concrete mixer; the solution can be prepared manually.

For a gazebo with a polycarbonate roof, the most practical option would be to fill in load-bearing elements - metal pipes on which the entire structure rests. This reduces the consumption of building materials (sand, cement, screenings) and simplifies the work. Mounting such a foundation does not require the use of a concrete mixer; the solution can be prepared manually.

A large consumption of concrete will be spent on filling the screed if the construction is carried out in order to create a durable structure. Then it is better to make a gazebo in the form of an extension to the house, which will allow you to combine the foundation of the gazebo with the foundation of the house and give additional stability to the entire building.

A large consumption of concrete will be spent on filling the screed if the construction is carried out in order to create a durable structure. Then it is better to make a gazebo in the form of an extension to the house, which will allow you to combine the foundation of the gazebo with the foundation of the house and give additional stability to the entire building.

Frame installation

This stage of work is very similar to assembling a large constructor. Here you do not need to make serious efforts, but you must follow the sequence of the procedure, as well as monitor the accuracy of the actions.

2 types of building material are used directly for the frame:

- metallic profile;

- wooden bar.

Wood, in any form, looks more attractive than metalwork, but it also requires proper care. And we should not forget about the rather high cost of wood. But it is easier to work with wood: it is enough to mark the structure, fasten the timber with self-tapping screws, and then process the building.

The profile gazebo has a very important quality - durability. The service life of the material is several decades. The profile does not require treatment with any protective substances. To connect the profiles, not self-tapping screws are used, as is the case with a wooden beam, but special screws.

The profile gazebo has a very important quality - durability. The service life of the material is several decades. The profile does not require treatment with any protective substances. To connect the profiles, not self-tapping screws are used, as is the case with a wooden beam, but special screws.

A gazebo made of metal and polycarbonate will serve its owner for a very long time, it is enough to install it correctly and beautifully.

Roof installation - the last stage of construction

It is the roof that is an important component of the polycarbonate gazebo for summer cottages. The final stage should be started only after finishing work with the frame. If the "skeleton" of the gazebo is firmly installed, securely fixed and does not have any defects, then you can work on the roof.

It is very convenient and simple to use a polycarbonate roof for a gazebo. The simplicity lies in the fact that the material can be easily cut into the necessary parts, which are then fixed to the frame. Some craftsmen perform such operations while right at the height.

Another important quality of polycarbonate is its acceptance of any shape. Of course, it will not work to wrap a sheet of plastic in a pipe, but bend it a little to give a flatter shape, quite. Therefore, polycarbonate garden gazebos can be made not only in a rectangular shape, but also with more stylish and beautiful curves.

Another important quality of polycarbonate is its acceptance of any shape. Of course, it will not work to wrap a sheet of plastic in a pipe, but bend it a little to give a flatter shape, quite. Therefore, polycarbonate garden gazebos can be made not only in a rectangular shape, but also with more stylish and beautiful curves.

Find out:1 hundred square meters how many meters!