Manual potato ridger

Many gardeners, at the time of planting potatoes, still use outdated farming methods. Initially, they make an approximate marking of the ridges, dig holes with a shovel, plant tubers and then cover them with earth with their hands. Hilling of potatoes is carried out with hoes, which complicates the process itself and makes it ineffective. Using homemade potato hillers - you can achieve a more rational result, which will save both time and physical strength. Read also:recipe for potato pancakes!

Many gardeners, at the time of planting potatoes, still use outdated farming methods. Initially, they make an approximate marking of the ridges, dig holes with a shovel, plant tubers and then cover them with earth with their hands. Hilling of potatoes is carried out with hoes, which complicates the process itself and makes it ineffective. Using homemade potato hillers - you can achieve a more rational result, which will save both time and physical strength. Read also:recipe for potato pancakes!

How does a manual hiller work?

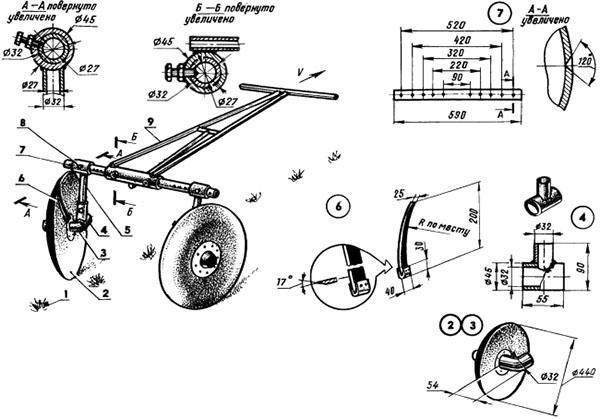

Drawings of a hand-made potato hiller, made by hand, can be found both on the Internet and in specialized magazines and brochures on this topic. He is able to significantly speed up and facilitate the processes of caring for the plot, and not only in the potato area. It is very convenient for them to cut beds and loosen the ground.

Drawings of a hand-made potato hiller, made by hand, can be found both on the Internet and in specialized magazines and brochures on this topic. He is able to significantly speed up and facilitate the processes of caring for the plot, and not only in the potato area. It is very convenient for them to cut beds and loosen the ground.

To make your own hiller, you must have the following materials:

- A hollow water pressure tube to be used as a vertical stand. The diameter is 1 inch and the length is 1 m.

- ”Hollow tube that is used for front and rear thrust.

- Sheet steel 2 mm thick, from which the dumps themselves are made;

- Lanyard required for the connecting part between the front link and the upright. It makes it possible to steplessly adjust the attacking angle. If it is not possible to find a lanyard, then the assembly of a manual disc hiller for potatoes, made by hand, may well take place with the help of a steel plate, in which holes are drilled for stepwise adjustment of the angle of inclination.

- A tool for bending pipes or a lamp for soldering, in special cases even a simple gas burner is suitable for heating metal parts in places where they are bent.

- Welding unit.

- Grinder for grinding seams.

How to assemble a hiller without resorting to the services of specialists

Any hiller must be multifunctional, so attention must be paid to the adaptability of its regulation. Height adjustment is carried out using a telescopic device in the central part. To do this, a tube is inserted into this tube with a smaller cross section, which passes into the rear thrust. This approach makes it possible, when cultivating the land, to adapt the hiller to the individual parameters of human growth.

Any hiller must be multifunctional, so attention must be paid to the adaptability of its regulation. Height adjustment is carried out using a telescopic device in the central part. To do this, a tube is inserted into this tube with a smaller cross section, which passes into the rear thrust. This approach makes it possible, when cultivating the land, to adapt the hiller to the individual parameters of human growth.

The attacking angle is controlled by tilting the center pillar in relation to its placement to the ground level. This effect is achieved by changing the angular difference between the vertical bed and the front link.

The attacking angle is controlled by tilting the center pillar in relation to its placement to the ground level. This effect is achieved by changing the angular difference between the vertical bed and the front link.

How to make a manual potato tiller on your own so that the tool frame is movable? To do this, the front link is connected to the central rack by a hinge, and the regulation itself is carried out with the participation of a lanyard. This allows you to change the angle of inclination gradually, depending on what type of soil you have to work on and on the parameters of the leading person.In the absence of a lanyard, the angle is adjusted by moving the plate to the required position and fixing it with bolts in the desired grooves.

The vertical bed tube is bent 40 cm from the end, the bending angle is 15 degrees.

This post is then welded to the rear link and the blades themselves, and the front link is secured using a hinge mechanism and a long bolt. The rear rod looks like a large letter "P", the width of which is 50 cm. The length of the handles is at least 20 cm. A vertical tube is welded in the center of the fork, it is 30 cm long, and with this end the structure is inserted into the cavity of the vertical rod.

To be able to adjust the height of the rack, openings are drilled at its upper end, and do the same with the vertical fork. The front link width must match the rear. However, the length of the handles of the front rods must correspond to the parameters of the owner, so that he can easily fit between the handrails and take them comfortably.

To make disc blades, two identical plates are cut from a steel sheet. They are given a semicircular shape, similar to the discs of a classic agricultural plow. Both halves of the plow are fixed to the vertical tine. The weld seam must be even, without chips. All welded parts must be grinded with a grinder, and the edges of the trimming discs must be sharpened. The undercutting part will take over the main soil resistance when working on the plot. You should not buy ready-made discs, since such metal can only be sharpened with the help of special and expensive equipment.

To make disc blades, two identical plates are cut from a steel sheet. They are given a semicircular shape, similar to the discs of a classic agricultural plow. Both halves of the plow are fixed to the vertical tine. The weld seam must be even, without chips. All welded parts must be grinded with a grinder, and the edges of the trimming discs must be sharpened. The undercutting part will take over the main soil resistance when working on the plot. You should not buy ready-made discs, since such metal can only be sharpened with the help of special and expensive equipment.