Hives for bees: device, varieties, do it yourself

In nature, wild bees are content with life in natural shelters, which most often become crevices and hollows in tree trunks. Life in apiaries is much more comfortable, because here each family is provided with its own bee hives.

In nature, wild bees are content with life in natural shelters, which most often become crevices and hollows in tree trunks. Life in apiaries is much more comfortable, because here each family is provided with its own bee hives.

How is a man-made house different from a primitive deck? What is the structure of a bee hive and can you build it yourself?

Common types of bee hives

Beekeeping is one of the oldest human activities. Therefore, it is not surprising that over the past time, many types and varieties of hives have appeared all over the world, which are conventionally divided into horizontal, or sun beds, and vertical, or risers:

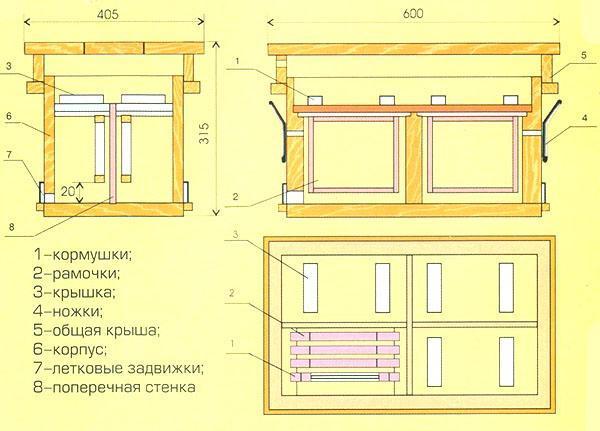

- Vertical structures increase upward due to extensions. Among the most common options are Dadant's multi-hull and hive.

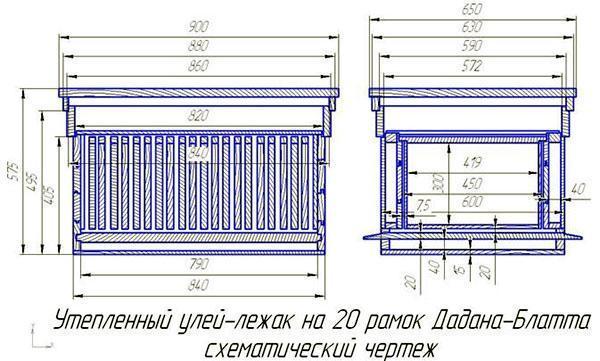

- Horizontal hives are built up in frames parallel to the ground. These varieties include sun loungers designed for 16-24 frames, as well as hives of Ukrainian design, which differ from the standard ones by the perpendicular arrangement of the frames.

Today, many types of hives are held in high esteem by beekeepers, but the most popular are sun beds, multi-hull structures and 12-frame hives. The price of bee hives depends on the size of the house, its design and the materials used for the manufacture. In addition to traditional wood and plywood, all kinds of plastic and textiles are often used when arranging hives.

Today, many types of hives are held in high esteem by beekeepers, but the most popular are sun beds, multi-hull structures and 12-frame hives. The price of bee hives depends on the size of the house, its design and the materials used for the manufacture. In addition to traditional wood and plywood, all kinds of plastic and textiles are often used when arranging hives.

Bee hives

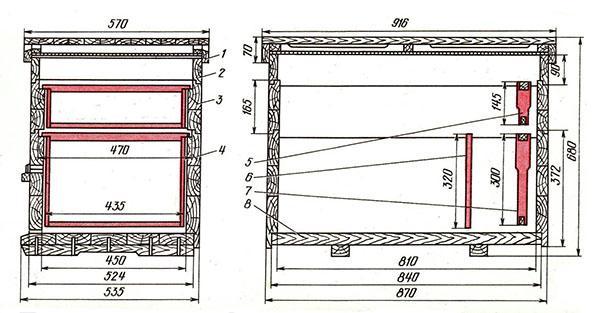

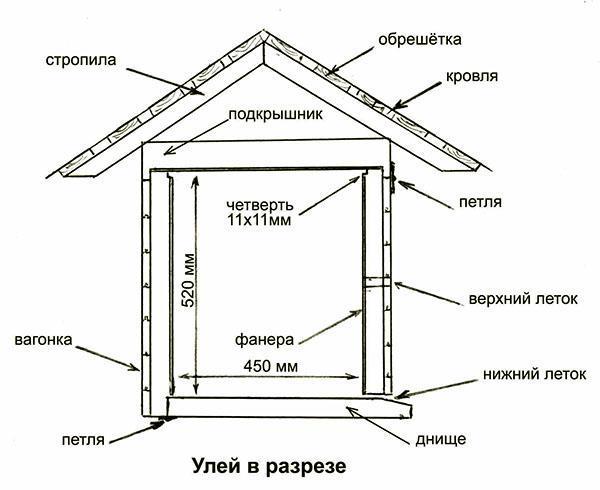

Structurally, typical hives consist of a body, a cover, a bottom, store extensions, frames for bees.

The main element of the device of the bee hive is the body containing the frames for the honeycomb and the bee colony itself. The exterior of the case is very simple. It is a box with no top and bottom and is equipped with frame holders.

For the departure and return of bees on the front wall of the hive body, an opening is provided - a taphole, which can be round or slit-like. For convenience, the taphole can be closed with a special latch. Its size can be easily adjusted with special inserts. And on the outside, below the taphole, an arrival board is installed.

From above, the body is covered with a lid, which is most often flat. The purpose of this structural part is to protect the inner space of the evidence for bees from bad weather, penetration of animals or parasitic insects. Under a flat roof, a roof cover is sometimes installed, which is required for the convenience of transporting hives, as well as for their insulation.

From above, the body is covered with a lid, which is most often flat. The purpose of this structural part is to protect the inner space of the evidence for bees from bad weather, penetration of animals or parasitic insects. Under a flat roof, a roof cover is sometimes installed, which is required for the convenience of transporting hives, as well as for their insulation.

From the bottom, the body covers the bottom of the bee hive. This part of the structure can be either removable or tightly attached to the main part. Outwardly, the bottom of the hive resembles a shield with edging along the edge.

From the bottom, the body covers the bottom of the bee hive. This part of the structure can be either removable or tightly attached to the main part. Outwardly, the bottom of the hive resembles a shield with edging along the edge.

A store extension is provided for fastening the semi-frames. It is half the height of the hive body and can be used during the period of mass collection of honey. If necessary, not one, but several stores are placed on the body.

Beginning beekeepers are reasonably concerned about the question: "How much is a hive with bees?" The cost of such an important purchase can vary greatly. At the same time, the choice of a specific device for a bee hive depends on the individual preferences of the beekeeper, the amount of honey obtained and the size of the families.

If the costs of ready-made hives seem too burdensome, the beekeeper decides to build bee hives with his own hands, drawings for such useful homemade products can be found in open sources, as well as take advantage of the experience of colleagues.

If the costs of ready-made hives seem too burdensome, the beekeeper decides to build bee hives with his own hands, drawings for such useful homemade products can be found in open sources, as well as take advantage of the experience of colleagues.

DIY clues for bees: material and assembly features

Whichever device of the bee hive was chosen, you should know that only materials that are safe for insects must be used to build a house.

Whichever device of the bee hive was chosen, you should know that only materials that are safe for insects must be used to build a house.

If wood is chosen as the basis, it is better to give preference to species that do not emit a viscous odorous resin.

Boards and bars must be thoroughly dried, otherwise, already during operation, deformation and failure of the hive are inevitable, it will lose its tightness, the frames for bees will stop falling into place. For the same reasons, it is better to avoid wood with an abundance of knots, which tend to fall out when dry.

For gluing the hives, they take natural moisture-resistant compounds that have not only high strength, but also help to seal the joints.

When connecting parts of the bottom, body, lid and other components of a hand-made evidence for bees, it is important not to allow gaps, and in order to avoid deformation, 2-3 pieces of a board are used for each of the parts.

External treatment of a hive for bees should include not only decorative coloring, but also mandatory two-time treatment with linseed oil, which ensures the resistance of the tree to moisture, temperature changes and the penetration of pests. It is recommended to paint with paint of a white, yellow or blue shade, well perceived by insects. It is useful to cover the cover of the hive with metal, and at the edges the sheets are tucked up so as to protect the cut points and ends.

External treatment of a hive for bees should include not only decorative coloring, but also mandatory two-time treatment with linseed oil, which ensures the resistance of the tree to moisture, temperature changes and the penetration of pests. It is recommended to paint with paint of a white, yellow or blue shade, well perceived by insects. It is useful to cover the cover of the hive with metal, and at the edges the sheets are tucked up so as to protect the cut points and ends.

Evidence requirements for bees

When planning how to make a hive for bees with your own hands, the drawings for the construction are chosen so that the new house is completely comfortable:

When planning how to make a hive for bees with your own hands, the drawings for the construction are chosen so that the new house is completely comfortable:

- A quality house fully protects insects from seasonal changes in temperature and humidity in all weather conditions. Why the hive is equipped with elements of ceiling and side protection, effective both in winter and in summer.

- The colony in the bee hive can expand without hindrance, for which a system for increasing the volume of the house is provided.

- The device of a bee hive should be convenient not only for insects, but also for the beekeeper. That is, the structure should be easily cleaned, disinfected, ventilated and revised.

- It must be remembered that the hives must be carried, assembled and disassembled.

Before making a bee hive, you need to decide on its size. Although many experienced beekeepers have their own preferences and practical options, it is better for beginners to focus on the accepted universal dimensions.

Focusing on the drawing of the bee hive, they make elements of the hulls, bottoms and lids, frames and other parts of the structure with their own hands:

- Dried boards with a thickness of 20 mm are taken for the manufacture of the case. At the same time, for frames, it is better to take the same boards not from conifers, but from deciduous ones, for example, birch or dense aspen.

- The distance between the frames for bees with a typical solution is 37.5 mm, and a gap of 20 mm is left between the bottom of the nest frame.

- Insect passages are 12.5 mm wide.

- An indent of 20 mm is made from the bottom to the lower frame of the frame.

- From the front or back of the bee hive body to the frames is 7.5 mm.

When making a hive, do not forget about insulation. For this purpose, they prepare insulation pillows with a side of 455 mm, which are stuffed with well-dried grass and moss.

The fencing of the living space of the hive from the not yet occupied area is a diaphragm. This detachable element of the bee hive device is also made by hand from a durable 10 mm plywood sheet.

The fencing of the living space of the hive from the not yet occupied area is a diaphragm. This detachable element of the bee hive device is also made by hand from a durable 10 mm plywood sheet.

The assembly of a homemade hive begins with the details of the body, then it is time to attach the frames for the bees. After checking that the dimensions are correct, the hive receives a bottom. The roof is installed last in place. The assembly is carried out on a flat surface so that the structure is stable and durable.

How to make a beehive with your own hands - video

Part 1

Part 2