How to make a lathe yourself from a drill

The carvings created by the hands of a master on a lathe are amazing, and I want to do something similar. A lathe from a drill installed on a bed from a foot sewing machine will allow you to get a souvenir from an inconspicuous bar. The tree is easy to process. For metal processing, a homemade machine needs to be more solid. A self-made lathe from a drill will not be left without work.

The carvings created by the hands of a master on a lathe are amazing, and I want to do something similar. A lathe from a drill installed on a bed from a foot sewing machine will allow you to get a souvenir from an inconspicuous bar. The tree is easy to process. For metal processing, a homemade machine needs to be more solid. A self-made lathe from a drill will not be left without work.

Lathe device

The piece of wood inserted into the lathe for machining must have a round shape. The ribs must first be folded so that the cutter runs smoothly over the surface.

For processing wood and plastic, you can make a simple structure that is easier to hide in a nook, even in an apartment.

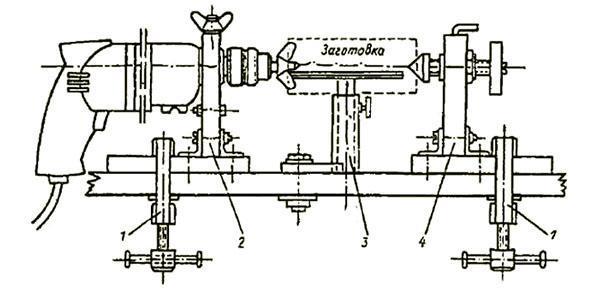

The diagram shows a homemade wood lathe from drill... The rig is installed on a stable platform with an axial through slot, made in any convenient way. A plate attached to a suitable structure is called a bed. This is the basis for the future machine. The size of the bed depends on the length of the workpieces, and the place for placing the working units:

The diagram shows a homemade wood lathe from drill... The rig is installed on a stable platform with an axial through slot, made in any convenient way. A plate attached to a suitable structure is called a bed. This is the basis for the future machine. The size of the bed depends on the length of the workpieces, and the place for placing the working units:

- headstock or leading center;

- tailstock;

- caliper or handyman.

If the motor providing the rotation of the driving part is used in the form of a drill, then the tool must be rigidly fixed with special clamps. A holder in the form of a faceplate is inserted into the chuck, with which the end of the workpiece is attached. The headstock can have one freedom of movement - along the axis. On lathes from a drill for metal, the headstock is welded to the bed tightly.

The center of the tailstock and the headstock are at the same height above the bed and along the axis. The positioning accuracy is important and controlled in relation to the slot on the table plane. The tailstock must have one degree of freedom. The inserted workpiece is clamped between the centers and then the back assembly is fixed.

The center of the tailstock and the headstock are at the same height above the bed and along the axis. The positioning accuracy is important and controlled in relation to the slot on the table plane. The tailstock must have one degree of freedom. The inserted workpiece is clamped between the centers and then the back assembly is fixed.

It is important to set the workpiece in the center so that it does not hit when rotating.

A cuff is called the middle insert, which is fixed under the workpiece. Sawdust falls into it, but the main purpose of the unit is to support the cutter from the working side. The master brings the cutter to the rotating rod, resting on the edge of the handbrake, which is located almost close to the line of rotation. The stop must have freedom of movement perpendicular to the longitudinal axis, it is removed when the workpiece is installed.

The handguard is also therefore vertically adjustable; it should be as close as possible to the work surface so that the turning tool rests against the rib. With large leverage, the tool is difficult to hold and can be pulled out with serious consequences. When grinding conical surfaces, the handcuff is set to the floor with an angle parallel to the cone.

Working on a lathe, you need to remember about your own safety. Always use safety glasses. Clothes should be tight. But hands must be open to feel the instrument.

A lathe from a drill with a collector motor is not a very successful design. Without a constant load, the motor picks up speed, it is "racing". Therefore, an electronic unit is provided to maintain a constant rotational speed. If there is no such device, a reducer is installed for safety reasons. Sometimes designs with high-speed mechanisms are connected via a belt drive. On the base drill factory-made lathes cost about 5,000 rubles.

Let's create a machine with our own hands

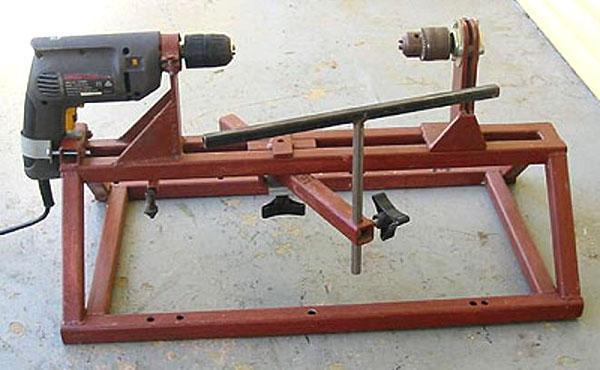

On a solid, stable base, such as a workbench, the drill head is mounted, representing the headstock. It must create conditions for the installation of the spindle so that the holes with the back are coaxial. As an example of creating a base, you can use the drawings of the proposed nodes.

An electric drill, which simultaneously serves as a headstock and an electric rotation drive, is fixed to such a surface with a clamp and a clamp fixed to the tool neck. However, it is possible to mount the drill on a hill above the bed, and then the second attachment point rises to the same height. There are many options for how to make a lathe out of a drill. The main thing is that the principle of axial alignment and reliable fixing of the workpiece is observed. It is to stabilize each node that it is important to think over the fasteners of clamps, drills.

An electric drill, which simultaneously serves as a headstock and an electric rotation drive, is fixed to such a surface with a clamp and a clamp fixed to the tool neck. However, it is possible to mount the drill on a hill above the bed, and then the second attachment point rises to the same height. There are many options for how to make a lathe out of a drill. The main thing is that the principle of axial alignment and reliable fixing of the workpiece is observed. It is to stabilize each node that it is important to think over the fasteners of clamps, drills.

In the process of work, you need to remember about the possible heating of the tool and stop the engine during rest.

Each job requires a certain power of equipment. Therefore, to create chess figures, a miniature machine is needed, and in order to create a curly lining of the sideboard, the dimensions of the bed and the power drive will have different parameters.

Is it possible to create a metal lathe from a drill

In practice, more monumental equipment is used for metal processing. It is important to have a welded stable bed, since the forces when acting on a rotating metal rod are much greater. The emphasis on the machine is on a reliable, screw-movable support. It is he who serves as the fulcrum for the cutter. The solid fastening of the drill with clamps creates a reliable fixing point for the workpiece in the chuck.

The whole structure is welded, including the tailstock. Only such a monolith can reliably accept loads during metal processing. On a lathe from a drill with your own hands, it is permissible to work with small workpieces from soft grades of metal. The material is processed using gentle methods - a file, a needle file, sandpaper. If it is necessary to work in deep processing, to create a profile with cutters, an adjustable slide is required.

The whole structure is welded, including the tailstock. Only such a monolith can reliably accept loads during metal processing. On a lathe from a drill with your own hands, it is permissible to work with small workpieces from soft grades of metal. The material is processed using gentle methods - a file, a needle file, sandpaper. If it is necessary to work in deep processing, to create a profile with cutters, an adjustable slide is required.

It is better to understand how to make a lathe for iron with your own hands, the video will help:

What can be done with a lathe

Even at the design stage of the machine, turning attachments for a drill can be provided. One of them might be a copier. It is used to repeat all curly cuts on a wooden cylinder exactly according to the pattern. Rewinding motors can be a problem, and a drill attachment will do the job. You can use a drill mounted on the bed for grinding, put a polishing pad on it.

Even at the design stage of the machine, turning attachments for a drill can be provided. One of them might be a copier. It is used to repeat all curly cuts on a wooden cylinder exactly according to the pattern. Rewinding motors can be a problem, and a drill attachment will do the job. You can use a drill mounted on the bed for grinding, put a polishing pad on it.

Rotate the workpiece to apply paint. When centrifugally spreading over the surface of the decorative layer, an unpredictable color mosaic is created. The first machine will awaken your interest in creativity and your imagination.

Using available inexpensive materials, you can create yourself an assistant with whom to sculpt exclusive things for your home. At all times, hand-made artwork was appreciated.